- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 16, 2025 04:49

Back to list

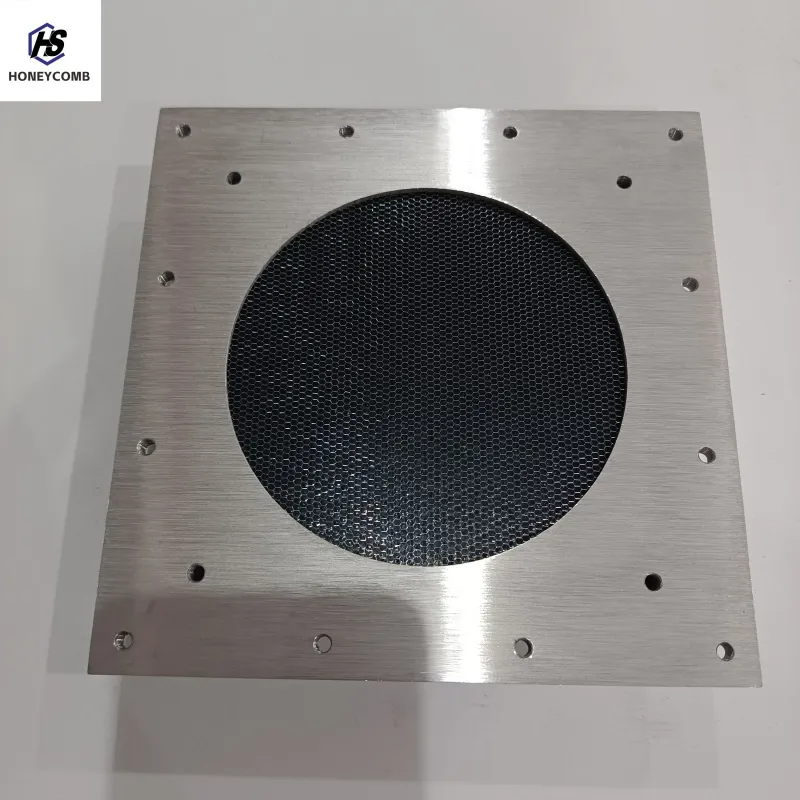

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

Honeycomb seals are a critical innovation in the realm of industrial equipment, offering unparalleled advantages in enhancing the efficiency and reliability of machinery. These seals are widely recognized for their distinctive honeycomb pattern, which consists of a porous structure that aids in controlling leakage and minimizing wear. This cutting-edge design is not just the result of meticulous engineering but decades of research and experience, making it one of the most trusted solutions in high-demand applications such as gas turbines, compressors, and various rotating equipment.

The credibility of honeycomb seals is underscored by numerous case studies documenting their successful deployment across various sectors. For instance, in the aerospace industry, these seals have proven pivotal in enhancing the performance and reliability of jet engines, leading to significant advances in fuel efficiency and emission reductions. In the oil and gas sector, honeycomb seals play an essential role in the operation of compressors, ensuring minimal leakage and optimal pressure control, which are critical for both safety and efficiency. The inherent trustworthiness of honeycomb seals is also reflected in the rigorous quality assurance processes undertaken during manufacturing. Each component is subjected to stringent testing protocols that simulate real-world operating conditions, guaranteeing that only the highest quality products reach the end-user. Furthermore, manufacturers offer comprehensive support services, including installation guidance and performance monitoring, to ensure that the integration of honeycomb seals into any system results in seamless operation and maximum benefit. In essence, honeycomb seals represent a pinnacle of modern engineering, merging innovative design with proven performance. Their role in enhancing operational efficiency, coupled with the assurance of quality and reliability, makes them an indispensable component across various high-stakes industries. As technology continues to evolve, honeycomb seals are poised to remain at the forefront, driving efficiency and sustainability in industrial applications around the globe.

The credibility of honeycomb seals is underscored by numerous case studies documenting their successful deployment across various sectors. For instance, in the aerospace industry, these seals have proven pivotal in enhancing the performance and reliability of jet engines, leading to significant advances in fuel efficiency and emission reductions. In the oil and gas sector, honeycomb seals play an essential role in the operation of compressors, ensuring minimal leakage and optimal pressure control, which are critical for both safety and efficiency. The inherent trustworthiness of honeycomb seals is also reflected in the rigorous quality assurance processes undertaken during manufacturing. Each component is subjected to stringent testing protocols that simulate real-world operating conditions, guaranteeing that only the highest quality products reach the end-user. Furthermore, manufacturers offer comprehensive support services, including installation guidance and performance monitoring, to ensure that the integration of honeycomb seals into any system results in seamless operation and maximum benefit. In essence, honeycomb seals represent a pinnacle of modern engineering, merging innovative design with proven performance. Their role in enhancing operational efficiency, coupled with the assurance of quality and reliability, makes them an indispensable component across various high-stakes industries. As technology continues to evolve, honeycomb seals are poised to remain at the forefront, driving efficiency and sustainability in industrial applications around the globe.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025