- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 00:54

Back to list

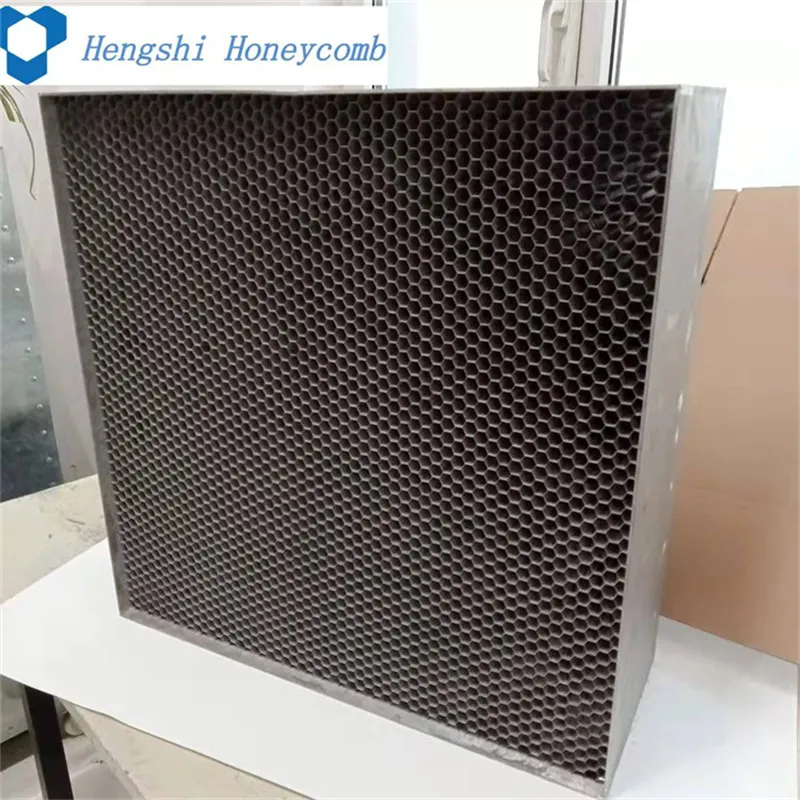

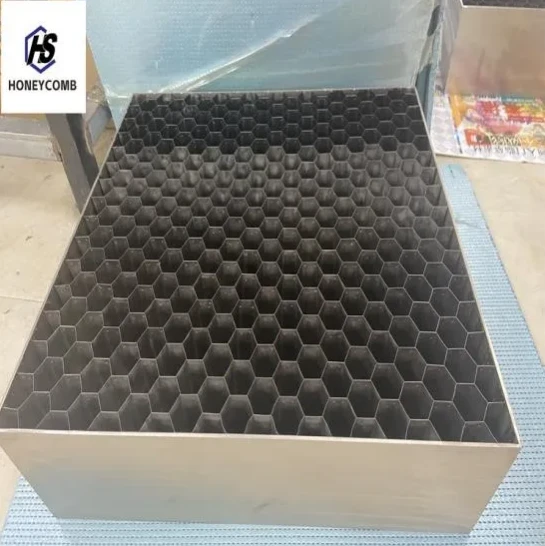

honeycomb sheet

Honeycomb sheets have transformed various industries with their remarkable properties, offering unique advantages that cater to a wide array of applications. Derived from the natural geometric design of honeycombs, these sheets excel in delivering superior strength-to-weight ratios, making them crucial for sectors that demand both durability and lightweight attributes.

The expertise required for manufacturing honeycomb sheets involves precision and high-quality material selection. It is critical that manufacturers maintain strict processes to ensure each sheet meets industry standards. Typically made from aluminum, paper, or advanced composites, these sheets undergo rigorous testing for compression, shear, and tensile strength. This adherence to quality reflects the establishment of trust between manufacturers and consumers, cementing the reliability of honeycomb technology. The versatility of honeycomb sheets extends to the realm of interior design as well. Designers utilize them in furniture to create pieces that are both aesthetically pleasing and functionally robust. Such practices highlight the adaptability of honeycomb sheets, showcasing their potential beyond traditional industrial applications. Trust in honeycomb sheet applications grows alongside emerging innovations. Researchers continue to explore biodegradable options within the honeycomb design framework, aiming to reduce the carbon footprint associated with production and disposal. These initiatives align with global sustainability goals and reflect the ongoing commitment of the material science community to enhance the eco-friendliness of honeycomb applications. The authoritative stance of honeycomb sheets in multiple industries underscores their indispensable role in contemporary material science. Investment in research and development further fortifies their position as an essential component in modern engineering and design solutions. In summation, honeycomb sheets stand as a testament to human ingenuity, echoing the efficiency of nature's blueprints. Their widespread use across various sectors reflects not only their mechanical superiority but also an unyielding trust in their capabilities to innovate and improve industry standards. As advancements continue, honeycomb sheets remain at the forefront, prepared to meet the demands of smarter and more sustainable solutions for the future.

The expertise required for manufacturing honeycomb sheets involves precision and high-quality material selection. It is critical that manufacturers maintain strict processes to ensure each sheet meets industry standards. Typically made from aluminum, paper, or advanced composites, these sheets undergo rigorous testing for compression, shear, and tensile strength. This adherence to quality reflects the establishment of trust between manufacturers and consumers, cementing the reliability of honeycomb technology. The versatility of honeycomb sheets extends to the realm of interior design as well. Designers utilize them in furniture to create pieces that are both aesthetically pleasing and functionally robust. Such practices highlight the adaptability of honeycomb sheets, showcasing their potential beyond traditional industrial applications. Trust in honeycomb sheet applications grows alongside emerging innovations. Researchers continue to explore biodegradable options within the honeycomb design framework, aiming to reduce the carbon footprint associated with production and disposal. These initiatives align with global sustainability goals and reflect the ongoing commitment of the material science community to enhance the eco-friendliness of honeycomb applications. The authoritative stance of honeycomb sheets in multiple industries underscores their indispensable role in contemporary material science. Investment in research and development further fortifies their position as an essential component in modern engineering and design solutions. In summation, honeycomb sheets stand as a testament to human ingenuity, echoing the efficiency of nature's blueprints. Their widespread use across various sectors reflects not only their mechanical superiority but also an unyielding trust in their capabilities to innovate and improve industry standards. As advancements continue, honeycomb sheets remain at the forefront, prepared to meet the demands of smarter and more sustainable solutions for the future.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025