- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 01:12

Back to list

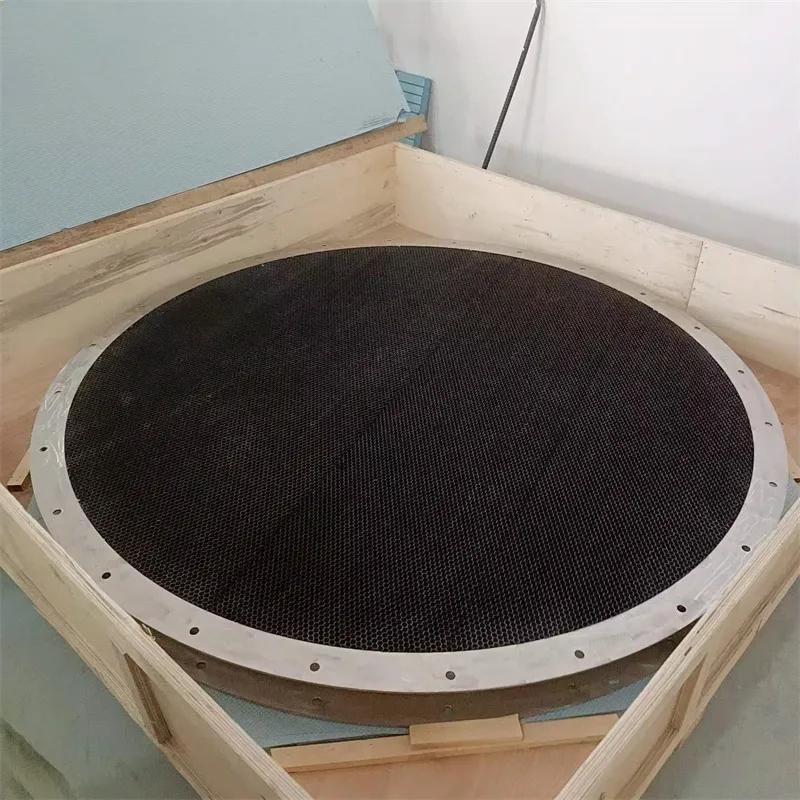

honeycomb sheets

Navigating the landscape of building materials, honeycomb sheets offer a distinctive edge that few materials can match. These sheets, inspired by the natural design of a honeybee's hive, provide a blend of strength, lightweight properties, and versatility that make them invaluable in various industries.

Trust in honeycomb sheets extends beyond their intrinsic properties. Leading-edge manufacturers ensure rigorous testing and certifications that meet international safety standards, guaranteeing reliability and safety in every application. It’s the blend of design ingenuity and manufacturing precision that empowers consumers to trust this material under a multitude of demanding conditions. End-users who have incorporated honeycomb sheets attest to their transformative capabilities. For instance, construction companies report a significant reduction in project timelines and costs, thanks to the ease of installation and reduced labor requirements relative to traditional building materials. In the realm of furniture design, honeycomb panels contribute to sleek, modern aesthetics with an underlying sturdiness that flatters any space, supporting everything from shelves to tables with grace and resilience. The challenges facing potential adopters mainly involve navigating the initial cost and understanding the integration nuances of these high-performance materials. However, the long-term benefits, including lifecycle cost savings and improved operational efficiencies, present a compelling case. Industry professionals often highlight training and education as critical components in maximizing the utility of honeycomb sheets, ensuring that stakeholders are adequately equipped to leverage all advantages comprehensively. Ultimately, honeycomb sheets are a testament to nature-inspired innovation meeting industrial demand. Their rising popularity is a direct response to a world increasingly moving towards materials that guarantee performance flexibility, sustainability, and economic value. By incorporating honeycomb technology, industries not only elevate their products but also align themselves with a future focused on smart, sustainable solutions.

Trust in honeycomb sheets extends beyond their intrinsic properties. Leading-edge manufacturers ensure rigorous testing and certifications that meet international safety standards, guaranteeing reliability and safety in every application. It’s the blend of design ingenuity and manufacturing precision that empowers consumers to trust this material under a multitude of demanding conditions. End-users who have incorporated honeycomb sheets attest to their transformative capabilities. For instance, construction companies report a significant reduction in project timelines and costs, thanks to the ease of installation and reduced labor requirements relative to traditional building materials. In the realm of furniture design, honeycomb panels contribute to sleek, modern aesthetics with an underlying sturdiness that flatters any space, supporting everything from shelves to tables with grace and resilience. The challenges facing potential adopters mainly involve navigating the initial cost and understanding the integration nuances of these high-performance materials. However, the long-term benefits, including lifecycle cost savings and improved operational efficiencies, present a compelling case. Industry professionals often highlight training and education as critical components in maximizing the utility of honeycomb sheets, ensuring that stakeholders are adequately equipped to leverage all advantages comprehensively. Ultimately, honeycomb sheets are a testament to nature-inspired innovation meeting industrial demand. Their rising popularity is a direct response to a world increasingly moving towards materials that guarantee performance flexibility, sustainability, and economic value. By incorporating honeycomb technology, industries not only elevate their products but also align themselves with a future focused on smart, sustainable solutions.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025