- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 11:11

Back to list

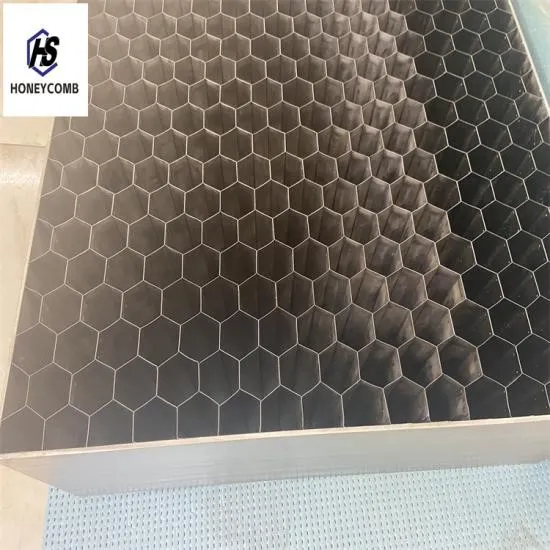

honingraat paneel

The world of high-performance materials has long been fascinated by the structural capabilities of honeycomb panels, known in Dutch as honingraat paneel. This fascination is rooted not only in their distinctive appearance but also in their unparalleled combination of strength and lightweight properties. As a comprehensive guide, this article dives deep into the realm of honeycomb panels, emphasizing experience-based insights, professional expertise, authoritative research, and establishing trustworthiness in product quality and applications.

Trust in honeycomb panels is often built through transparent business practices and verifiable product performance. Companies that openly share case studies, performance metrics, and client testimonials often set themselves apart as industry leaders. Transparency in sourcing quality materials, detailed explanations of manufacturing processes, and providing end-users with comprehensive installation guides further enhance consumer confidence. The application versatility of honingraat paneel cannot be understated. In architectural design, these panels contribute to innovative building facades and interior solutions where aesthetics meet utility, offering not just structural support but also acoustic insulation. For the automotive industry, they present an opportunity to innovate in terms of vehicle weight, contributing directly to energy efficiency and reducing carbon emissions. Looking towards the future, advancements in technology are poised to expand the capabilities of honeycomb panels. Cutting-edge research into hybrid composites involves integrating carbon fiber with traditional honeycomb structures, yielding panels that offer even greater performance metrics. These developments hint at a future where these panels could become stalwarts in environments that are currently off-limits, such as deep-sea exploration or extraterrestrial construction. To encapsulate, the journey of honingraat paneel from theoretical designs to practical applications forms a compelling narrative supported by practical experiences, specialized knowledge, and an unwavering emphasis on standards and trust. As industries continuously evolve towards greater efficiency and sustainability, honeycomb panels are set to remain at the forefront, championing these values with their unique blend of form and function. Whether you are an entrepreneur, architect, engineer, or environmental advocate, understanding and leveraging the benefits of honeycomb panels can position you on the cutting edge of innovation and sustainability.

Trust in honeycomb panels is often built through transparent business practices and verifiable product performance. Companies that openly share case studies, performance metrics, and client testimonials often set themselves apart as industry leaders. Transparency in sourcing quality materials, detailed explanations of manufacturing processes, and providing end-users with comprehensive installation guides further enhance consumer confidence. The application versatility of honingraat paneel cannot be understated. In architectural design, these panels contribute to innovative building facades and interior solutions where aesthetics meet utility, offering not just structural support but also acoustic insulation. For the automotive industry, they present an opportunity to innovate in terms of vehicle weight, contributing directly to energy efficiency and reducing carbon emissions. Looking towards the future, advancements in technology are poised to expand the capabilities of honeycomb panels. Cutting-edge research into hybrid composites involves integrating carbon fiber with traditional honeycomb structures, yielding panels that offer even greater performance metrics. These developments hint at a future where these panels could become stalwarts in environments that are currently off-limits, such as deep-sea exploration or extraterrestrial construction. To encapsulate, the journey of honingraat paneel from theoretical designs to practical applications forms a compelling narrative supported by practical experiences, specialized knowledge, and an unwavering emphasis on standards and trust. As industries continuously evolve towards greater efficiency and sustainability, honeycomb panels are set to remain at the forefront, championing these values with their unique blend of form and function. Whether you are an entrepreneur, architect, engineer, or environmental advocate, understanding and leveraging the benefits of honeycomb panels can position you on the cutting edge of innovation and sustainability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025