- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 11:29

Back to list

industriële honingraat

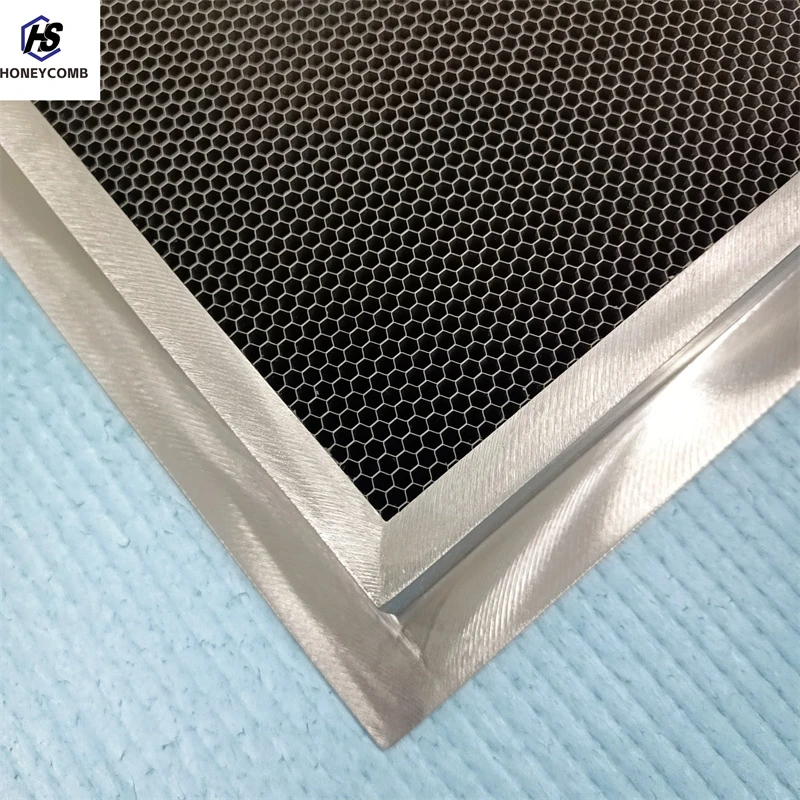

Industrial honeycomb structures have been revolutionizing various sectors, from aerospace to construction, due to their remarkable balance of strength, weight, and versatility. This extraordinary configuration, inspired by natural honeycombs, offers unparalleled advantages for industries requiring robust yet lightweight materials.

The consistent evolution in industrial honeycomb technology also highlights its importance in packaging solutions. Companies demand sustainable and lightweight packaging materials to reduce transportation costs and environmental impact. Honeycomb panels offer exceptional cushioning and protection, safeguarding goods during transit while decreasing the carbon footprint associated with packaging materials. The growing reliance on these structures underlines the need for stringent quality control and testing standards. Manufacturers must adhere to exact engineering specifications to ensure safety and performance. These standards are critical to maintaining credibility and trustworthiness within the industry. As a result, leading manufacturers invest in advanced testing facilities and quality assurance protocols to meet these rigorous demands. Furthermore, the environmental implications of industrial honeycomb structures cannot be overlooked. The materials used in these structures are typically recyclable, aligning with circular economy principles. Many manufacturers prioritize sourcing sustainable materials and optimizing production methodologies to minimize environmental impact, enhancing the ecological appeal of these structures. The future of industrial honeycomb technology looks promising, with ongoing research focused on enhancing material properties and expanding application possibilities. As industries worldwide face mounting pressure to innovate and improve efficiency, these structures stand out as pivotal components that can drive advancements in performance, sustainability, and cost-effectiveness. Stakeholders, from engineers to environmental scientists, agree that the integration of industrial honeycomb structures will play a central role in shaping the future of numerous sectors. Their versatility and adaptability ensure a wide array of applications, potentially transforming entire industries. In Conclusion, industrial honeycomb structures epitomize the synergy between nature-inspired innovation and cutting-edge engineering. Their widespread application across diverse industries underscores their unmatched capabilities in improving strength, reducing weight, and promoting sustainable practices. As technology continues to evolve, there is little doubt that the role of industrial honeycombs will expand, ushering in an era of enhanced industrial performance and ecological responsibility.

The consistent evolution in industrial honeycomb technology also highlights its importance in packaging solutions. Companies demand sustainable and lightweight packaging materials to reduce transportation costs and environmental impact. Honeycomb panels offer exceptional cushioning and protection, safeguarding goods during transit while decreasing the carbon footprint associated with packaging materials. The growing reliance on these structures underlines the need for stringent quality control and testing standards. Manufacturers must adhere to exact engineering specifications to ensure safety and performance. These standards are critical to maintaining credibility and trustworthiness within the industry. As a result, leading manufacturers invest in advanced testing facilities and quality assurance protocols to meet these rigorous demands. Furthermore, the environmental implications of industrial honeycomb structures cannot be overlooked. The materials used in these structures are typically recyclable, aligning with circular economy principles. Many manufacturers prioritize sourcing sustainable materials and optimizing production methodologies to minimize environmental impact, enhancing the ecological appeal of these structures. The future of industrial honeycomb technology looks promising, with ongoing research focused on enhancing material properties and expanding application possibilities. As industries worldwide face mounting pressure to innovate and improve efficiency, these structures stand out as pivotal components that can drive advancements in performance, sustainability, and cost-effectiveness. Stakeholders, from engineers to environmental scientists, agree that the integration of industrial honeycomb structures will play a central role in shaping the future of numerous sectors. Their versatility and adaptability ensure a wide array of applications, potentially transforming entire industries. In Conclusion, industrial honeycomb structures epitomize the synergy between nature-inspired innovation and cutting-edge engineering. Their widespread application across diverse industries underscores their unmatched capabilities in improving strength, reducing weight, and promoting sustainable practices. As technology continues to evolve, there is little doubt that the role of industrial honeycombs will expand, ushering in an era of enhanced industrial performance and ecological responsibility.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025