- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 05, 2025 02:18

Back to list

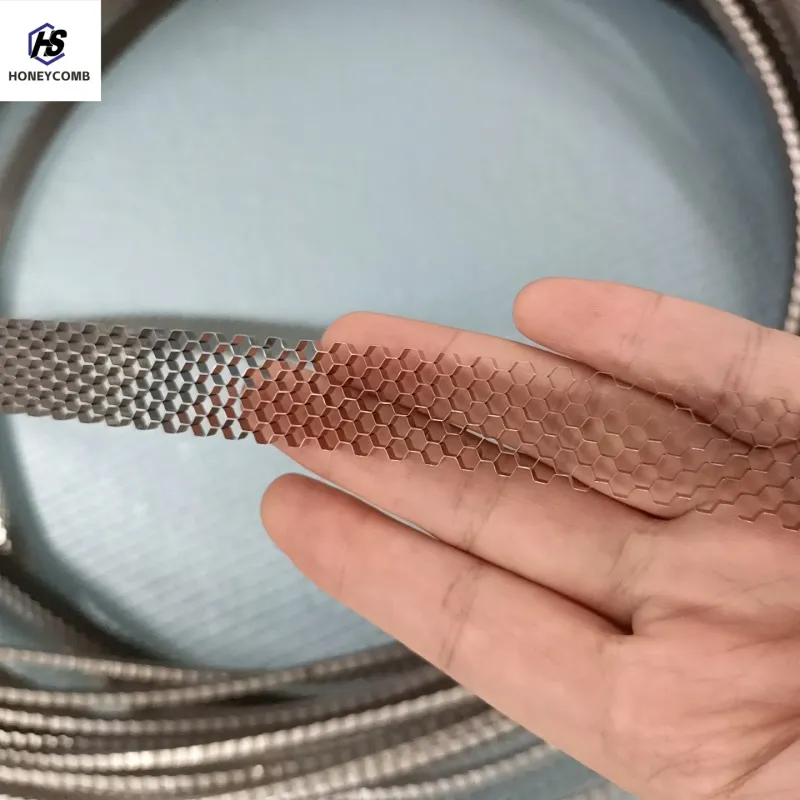

maf honeycomb screen

Nest honeycomb panels, with their distinctive structure, have revolutionized various industries due to their excellent strength-to-weight ratio and versatile applications. Commonly used in aerospace, construction, and interior design, these panels offer significant benefits that extend beyond their basic physical properties. They are a testament to engineering innovation, bringing both functional and aesthetic advantages.

Despite their many advantages, the production and customization of honeycomb panels require a deep understanding of materials science and engineering. The choice of materials for the core and skins can vary based on application requirements. For instance, aluminum honeycomb panels provide corrosion resistance and are suitable for environments exposed to moisture, while paper-based cores are often employed for temporary structures where biodegradability is a concern. Manufacturers must possess technical expertise and advanced production capabilities to deliver panels that meet specific project needs while maintaining structural integrity and aesthetic appeal. Trust in honeycomb panel solutions comes from not only their inherent qualities but also from the reputation of manufacturers and suppliers. A proven track record in producing high-quality panels is essential. Look for certifications and compliance with international standards as indicators of a product's credibility. Partnering with industry experts who offer a comprehensive understanding of material properties, design implications, and installation techniques is crucial in achieving successful project outcomes. The future of honeycomb panels looks promising as research and innovation continue to enhance their capabilities. Developments in materials science may introduce even more sustainable and efficient variants. An increased focus on green technologies and circular economy principles suggests that the life cycle of honeycomb panels, from production through recycling, will become even more environmentally friendly. As industries strive to meet evolving demands for efficient, lightweight, and sustainable materials, honeycomb panels will undoubtedly remain at the forefront of these advancements. In conclusion, honeycomb panels epitomize the blend of natural inspiration and technological prowess. Their multifaceted applications across various sectors underline their importance in modern design and engineering. With continuous innovations and an emphasis on sustainable practices, honeycomb panels will continue to shape the future of numerous industries, providing solutions that balance functionality with ecological responsibility.

Despite their many advantages, the production and customization of honeycomb panels require a deep understanding of materials science and engineering. The choice of materials for the core and skins can vary based on application requirements. For instance, aluminum honeycomb panels provide corrosion resistance and are suitable for environments exposed to moisture, while paper-based cores are often employed for temporary structures where biodegradability is a concern. Manufacturers must possess technical expertise and advanced production capabilities to deliver panels that meet specific project needs while maintaining structural integrity and aesthetic appeal. Trust in honeycomb panel solutions comes from not only their inherent qualities but also from the reputation of manufacturers and suppliers. A proven track record in producing high-quality panels is essential. Look for certifications and compliance with international standards as indicators of a product's credibility. Partnering with industry experts who offer a comprehensive understanding of material properties, design implications, and installation techniques is crucial in achieving successful project outcomes. The future of honeycomb panels looks promising as research and innovation continue to enhance their capabilities. Developments in materials science may introduce even more sustainable and efficient variants. An increased focus on green technologies and circular economy principles suggests that the life cycle of honeycomb panels, from production through recycling, will become even more environmentally friendly. As industries strive to meet evolving demands for efficient, lightweight, and sustainable materials, honeycomb panels will undoubtedly remain at the forefront of these advancements. In conclusion, honeycomb panels epitomize the blend of natural inspiration and technological prowess. Their multifaceted applications across various sectors underline their importance in modern design and engineering. With continuous innovations and an emphasis on sustainable practices, honeycomb panels will continue to shape the future of numerous industries, providing solutions that balance functionality with ecological responsibility.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025