- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 05, 2025 02:52

Back to list

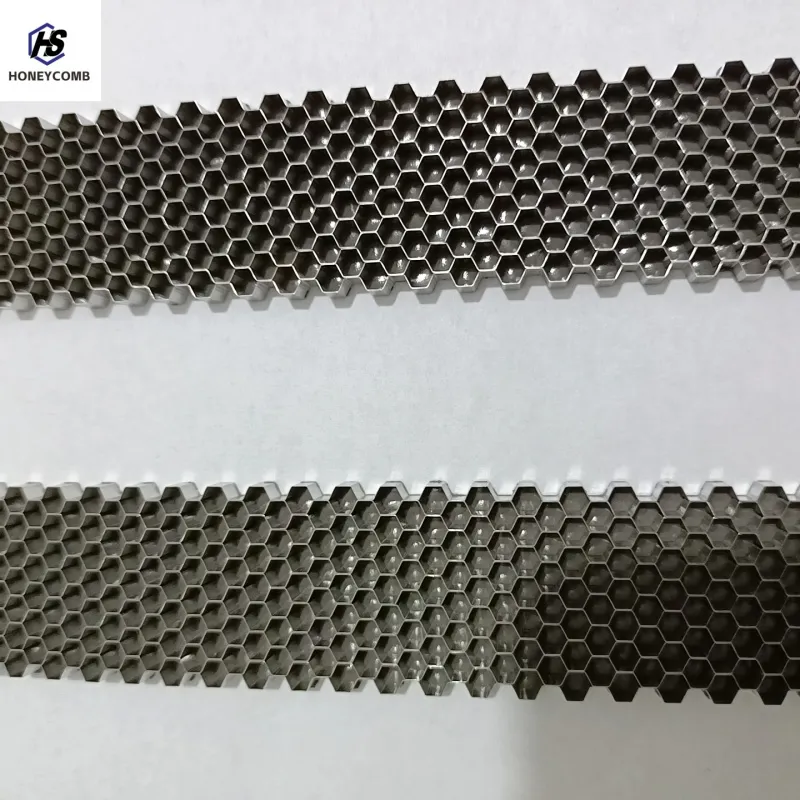

air flow straightener

The exceptional versatility of honeycomb core materials has cemented their position as indispensable components in modern engineering and design. These materials derive their unparalleled performance from their structural geometry, which mirrors the natural efficiency of a bee's nest. The meticulous arrangement offers optimal strength-to-weight ratios, making them the material of choice for industries where performance, durability, and weight efficiency take precedence.

Manufacturing with honeycomb core materials extends beyond the macro scale, too, into everyday products that demand a balance of durability and weight efficiency. In sporting goods, for example, the performance of bicycles, skis, and surfboards is markedly enhanced through the strategic use of these cores. The same benefits are seen in protective gear, where both professional athletes and casual users rely on the superior impact absorption and distribution properties of honeycomb structures to safeguard against injuries. Innovation and adaptability align perfectly with honeycomb core materials. As industries pivot towards sustainability, the recyclability and eco-friendly nature of these materials become increasingly paramount. Water-based adhesives and non-toxic resins ensure that their production has a minimal environmental footprint. Moreover, ongoing advancements in material science seek to enhance the capabilities of honeycomb structures further, optimizing them for use in ever-more demanding conditions and broadening their application scope. The authority of honeycomb core materials in various industries is reinforced by ongoing research and technological development. Paralleling the natural design seen in beehives, these materials demonstrate an innate equilibrium between structural performance and resource efficiency. Trust arises from decades of empirical evidence and practical application that confirm their role as pivotal components in advancing technology and design efficiency. Emphasizing expertise, those working extensively with honeycomb core materials draw upon a wealth of knowledge in engineering and physics to exploit their full potential. The recurring theme across various applications is their contribution to sustainability and efficiency without a trade-off in quality or reliability. For any organization, whether pioneering aerodynamics or setting new standards in sustainable architecture, honeycomb core materials offer an unparalleled opportunity to innovate with confidence and authority. Their capacity to enhance product performance while supporting eco-conscious manufacturing underpins the material's enduring relevance and trusted status among engineers, designers, and manufacturers worldwide.

Manufacturing with honeycomb core materials extends beyond the macro scale, too, into everyday products that demand a balance of durability and weight efficiency. In sporting goods, for example, the performance of bicycles, skis, and surfboards is markedly enhanced through the strategic use of these cores. The same benefits are seen in protective gear, where both professional athletes and casual users rely on the superior impact absorption and distribution properties of honeycomb structures to safeguard against injuries. Innovation and adaptability align perfectly with honeycomb core materials. As industries pivot towards sustainability, the recyclability and eco-friendly nature of these materials become increasingly paramount. Water-based adhesives and non-toxic resins ensure that their production has a minimal environmental footprint. Moreover, ongoing advancements in material science seek to enhance the capabilities of honeycomb structures further, optimizing them for use in ever-more demanding conditions and broadening their application scope. The authority of honeycomb core materials in various industries is reinforced by ongoing research and technological development. Paralleling the natural design seen in beehives, these materials demonstrate an innate equilibrium between structural performance and resource efficiency. Trust arises from decades of empirical evidence and practical application that confirm their role as pivotal components in advancing technology and design efficiency. Emphasizing expertise, those working extensively with honeycomb core materials draw upon a wealth of knowledge in engineering and physics to exploit their full potential. The recurring theme across various applications is their contribution to sustainability and efficiency without a trade-off in quality or reliability. For any organization, whether pioneering aerodynamics or setting new standards in sustainable architecture, honeycomb core materials offer an unparalleled opportunity to innovate with confidence and authority. Their capacity to enhance product performance while supporting eco-conscious manufacturing underpins the material's enduring relevance and trusted status among engineers, designers, and manufacturers worldwide.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025