- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 05, 2025 03:24

Back to list

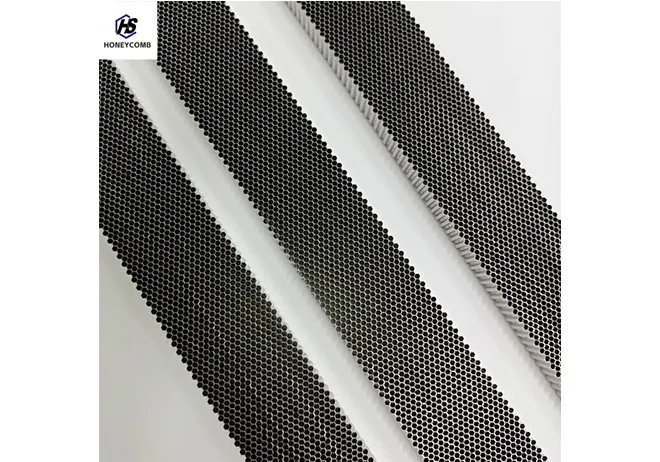

wind tunnel honeycomb

In the vast realm of aerospace technology, the term panal aeroespacial emerges as a focal keyword, drawing attention to advanced aerospace panels crucial in modern aviation and aerospace industries. These panels form the backbone of various aerospace structures, from humble aircraft interiors to sophisticated satellite exteriors. Delving into their significance requires examining real-world applications, expert insights, and industry advancements, ensuring an authoritative and trustworthy analysis.

Trustworthiness in aerospace panel production hinges upon the adherence to international standards such as AS9100, which delineates quality management requirements for the aerospace sector. Certified manufacturers conform to these standards, providing reassurance to stakeholders and users about the integrity and reliability of aerospace panels. The trust is further cemented through rigorous testing protocols like non-destructive testing (NDT), which assesses the structural integrity of panels without causing damage, ensuring they are fit for use in critical aerospace applications. The impact of aerospace panels extends beyond mere functional components; they play a pivotal role in environmental sustainability. The shift towards lightweight, durable panels contributes significantly to reducing the carbon footprint of flights. Lighter aircraft demand less fuel, leading to lower emissions. Moreover, initiatives focusing on recyclable composites underscore the industry’s commitment to sustainable practices, looking to create a circular economy in aerospace materials. Ultimately, the future of aerospace panels looks promising, with burgeoning technologies such as 3D printing poised to redefine manufacturing approaches. 3D printing holds the promise of producing complex panel geometries with unprecedented precision, reducing material wastage and lowering production costs. This technological leap is anticipated to open new frontiers in aerospace design and performance, reinforcing the role of aerospace panels as fundamental enablers of innovation in the aerospace industry. In conclusion, aerospace panels, embodied in the concept of panal aeroespacial, are fundamental to modern aviation and aerospace exploration. Their development is a testament to human ingenuity, rooted in experience, guided by expertise, governed by authority, and upheld by trust. These elements, combined with ongoing advancements, ensure that aerospace panels remain at the forefront of aerospace progress, continually shaping the future of flight and space exploration.

Trustworthiness in aerospace panel production hinges upon the adherence to international standards such as AS9100, which delineates quality management requirements for the aerospace sector. Certified manufacturers conform to these standards, providing reassurance to stakeholders and users about the integrity and reliability of aerospace panels. The trust is further cemented through rigorous testing protocols like non-destructive testing (NDT), which assesses the structural integrity of panels without causing damage, ensuring they are fit for use in critical aerospace applications. The impact of aerospace panels extends beyond mere functional components; they play a pivotal role in environmental sustainability. The shift towards lightweight, durable panels contributes significantly to reducing the carbon footprint of flights. Lighter aircraft demand less fuel, leading to lower emissions. Moreover, initiatives focusing on recyclable composites underscore the industry’s commitment to sustainable practices, looking to create a circular economy in aerospace materials. Ultimately, the future of aerospace panels looks promising, with burgeoning technologies such as 3D printing poised to redefine manufacturing approaches. 3D printing holds the promise of producing complex panel geometries with unprecedented precision, reducing material wastage and lowering production costs. This technological leap is anticipated to open new frontiers in aerospace design and performance, reinforcing the role of aerospace panels as fundamental enablers of innovation in the aerospace industry. In conclusion, aerospace panels, embodied in the concept of panal aeroespacial, are fundamental to modern aviation and aerospace exploration. Their development is a testament to human ingenuity, rooted in experience, guided by expertise, governed by authority, and upheld by trust. These elements, combined with ongoing advancements, ensure that aerospace panels remain at the forefront of aerospace progress, continually shaping the future of flight and space exploration.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025