- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 08:00

Back to list

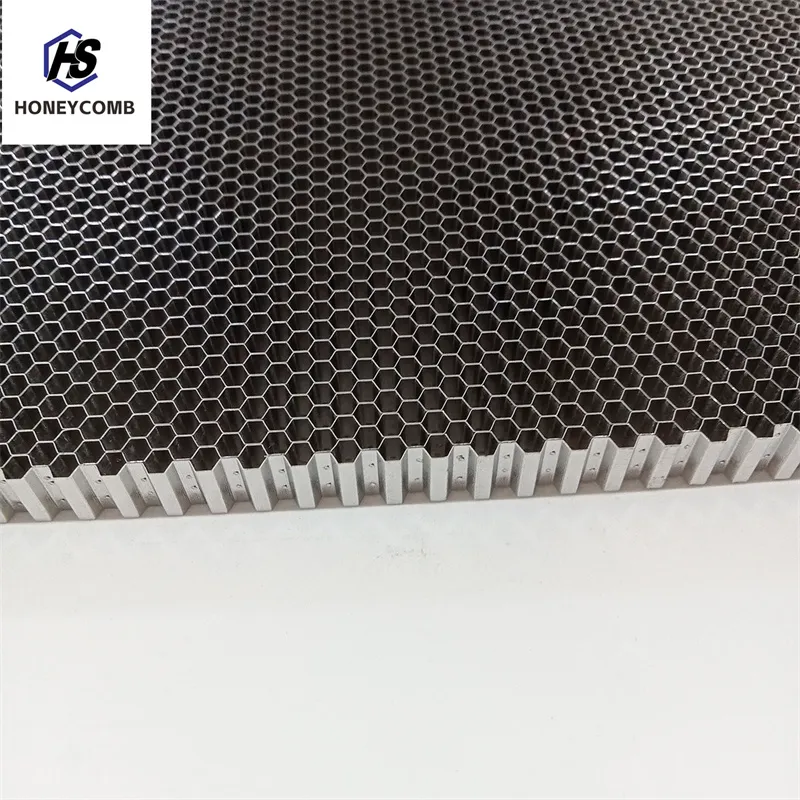

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The MAF-Wabensieb, a term that might not immediately ring bells for some, stands as a pioneer when it comes to mesh screening technology. This unique product bridges the gap between efficiency and reliability, offering industries an undeniable tool that enhances productivity while maintaining superior quality. But what makes MAF-Wabensieb not just another mesh screen in the market?

Authoritative industry leaders have endorsed the MAF-Wabensieb, recognizing its potential to safeguard quality while enhancing yield. For sectors where the integrity of the final product is non-negotiable, the MAF-Wabensieb ensures that contaminants are meticulously filtered out during the production process, thereby guaranteeing the purity and quality of the end product. Furthermore, trust in the MAF-Wabensieb has been cultivated over time by its manufacturer’s responsiveness and commitment to customer service. Users have consistently praised the support team for providing knowledgeable assistance and timely interventions whenever required. This level of customer interaction has fortified the MAF-Wabensieb’s reputation as not just a product, but a partnership enterprise. The MAF-Wabensieb doesn't just adapt to industry needs; it anticipates them. Its design has been refined to align with the evolving technologies and methodologies in industrial screening practices. As industries push towards more sustainable and energy-efficient methods, the MAF-Wabensieb stands ready to support those initiatives with eco-friendly and energy-efficient models that do not sacrifice performance. In conclusion, the MAF-Wabensieb is more than a product; it is a symbol of technological advancement and industrial expertise. It embodies a harmony of efficiency, reliability, and innovation, making it indispensable for businesses wishing to remain competitive in an ever-evolving industrial landscape. As firms continue to seek products that deliver exceptional performance without compromising quality, the MAF-Wabensieb emerges as a steadfast solution that promises and delivers excellence.

Authoritative industry leaders have endorsed the MAF-Wabensieb, recognizing its potential to safeguard quality while enhancing yield. For sectors where the integrity of the final product is non-negotiable, the MAF-Wabensieb ensures that contaminants are meticulously filtered out during the production process, thereby guaranteeing the purity and quality of the end product. Furthermore, trust in the MAF-Wabensieb has been cultivated over time by its manufacturer’s responsiveness and commitment to customer service. Users have consistently praised the support team for providing knowledgeable assistance and timely interventions whenever required. This level of customer interaction has fortified the MAF-Wabensieb’s reputation as not just a product, but a partnership enterprise. The MAF-Wabensieb doesn't just adapt to industry needs; it anticipates them. Its design has been refined to align with the evolving technologies and methodologies in industrial screening practices. As industries push towards more sustainable and energy-efficient methods, the MAF-Wabensieb stands ready to support those initiatives with eco-friendly and energy-efficient models that do not sacrifice performance. In conclusion, the MAF-Wabensieb is more than a product; it is a symbol of technological advancement and industrial expertise. It embodies a harmony of efficiency, reliability, and innovation, making it indispensable for businesses wishing to remain competitive in an ever-evolving industrial landscape. As firms continue to seek products that deliver exceptional performance without compromising quality, the MAF-Wabensieb emerges as a steadfast solution that promises and delivers excellence.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025