- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 07:40

Back to list

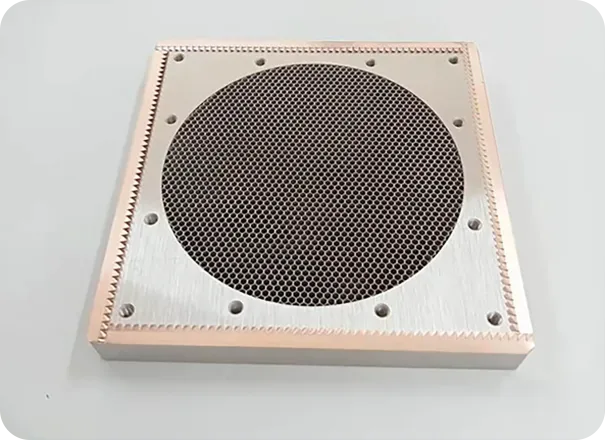

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

MAF (Mass Air Flow) sensors are crucial components in modern vehicles, playing a pivotal role in maintaining efficient engine performance. The term Luftstromgleichrichter, a German word roughly translating to air flow rectifier, refers to a device utilized within these sensors to ensure accurate air flow measurement. This intricately-designed component provides remarkable benefits for automotive technology, and demands keen attention to detail to harness its full potential.

From a professional standpoint, expertise in the application and integration of Luftstromgleichrichters is highly valued within the automotive sector. Engineers and technologists specializing in air flow management device design dedicate significant resources to research and development. Working at the intersection of aerodynamics and electronic engineering, they continuously strive to enhance the effectiveness of these components. This cumulative expertise results in innovations that raise industry standards and drive the development of more efficient and eco-friendly vehicles. Manufacturers are not the sole custodians of their success; automotive technicians also play a vital role in ensuring the proper functioning of MAF sensors with Luftstromgleichrichters. Regular diagnostics and careful installation are necessary to maximize their benefits. A meticulous approach, combined with an in-depth understanding of the sensor's operational mechanics, allows technicians to identify potential issues early and maintain the vehicle’s optimal performance. Reflecting on the Luftstromgleichrichter's significance, its application transcends mere technical specifications. It embodies a commitment to sustainable automotive engineering. The implementation of this component aligns with the broader industry movement towards green technologies, reducing carbon footprints while satisfying regulatory standards. Its small yet profound impact contributes to a cleaner environment and reflects a commitment to corporate responsibility in safeguarding the planet. In essence, the Luftstromgleichrichter within a MAF sensor is a testament to the convergence of innovation, expertise, and reliability in the automotive sphere. From enhancing fuel efficiency and reducing emissions to ensuring consistent engine performance across diverse conditions, its contribution is invaluable. As the automotive industry continues to evolve, the Luftstromgleichrichter will remain a key player in the pursuit of smarter, cleaner, and more efficient vehicle designs.

From a professional standpoint, expertise in the application and integration of Luftstromgleichrichters is highly valued within the automotive sector. Engineers and technologists specializing in air flow management device design dedicate significant resources to research and development. Working at the intersection of aerodynamics and electronic engineering, they continuously strive to enhance the effectiveness of these components. This cumulative expertise results in innovations that raise industry standards and drive the development of more efficient and eco-friendly vehicles. Manufacturers are not the sole custodians of their success; automotive technicians also play a vital role in ensuring the proper functioning of MAF sensors with Luftstromgleichrichters. Regular diagnostics and careful installation are necessary to maximize their benefits. A meticulous approach, combined with an in-depth understanding of the sensor's operational mechanics, allows technicians to identify potential issues early and maintain the vehicle’s optimal performance. Reflecting on the Luftstromgleichrichter's significance, its application transcends mere technical specifications. It embodies a commitment to sustainable automotive engineering. The implementation of this component aligns with the broader industry movement towards green technologies, reducing carbon footprints while satisfying regulatory standards. Its small yet profound impact contributes to a cleaner environment and reflects a commitment to corporate responsibility in safeguarding the planet. In essence, the Luftstromgleichrichter within a MAF sensor is a testament to the convergence of innovation, expertise, and reliability in the automotive sphere. From enhancing fuel efficiency and reducing emissions to ensuring consistent engine performance across diverse conditions, its contribution is invaluable. As the automotive industry continues to evolve, the Luftstromgleichrichter will remain a key player in the pursuit of smarter, cleaner, and more efficient vehicle designs.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025