- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 07:19

Back to list

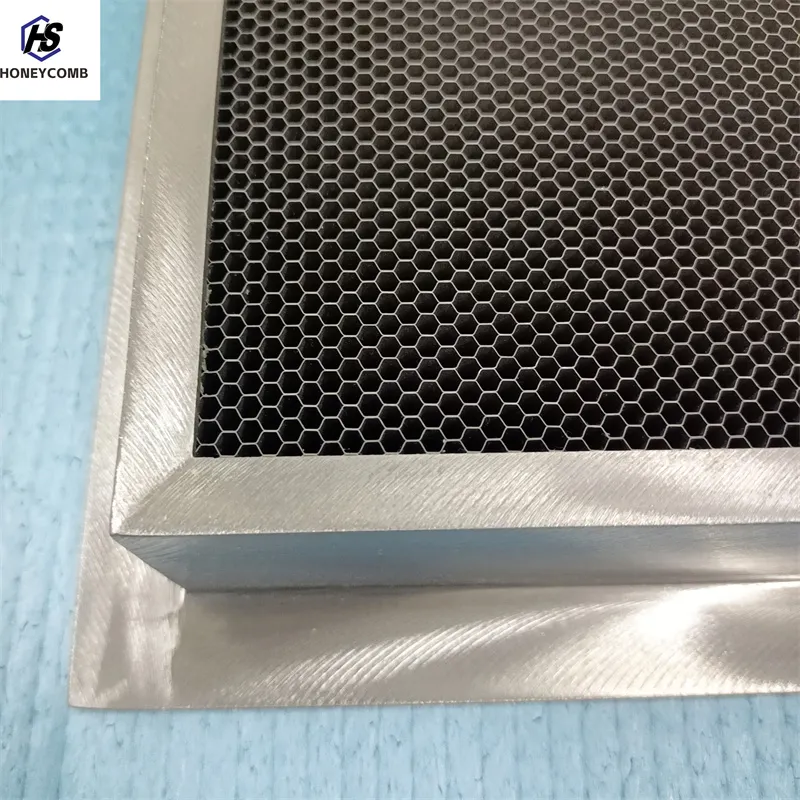

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The MAF Glätter, a groundbreaking innovation in the field of surface finishing, represents a transformative leap for industries requiring impeccable surface smoothness and precision. This advanced tool addresses the nuanced needs of modern manufacturing, showcasing not only sophisticated engineering but also significant enhancements in operational efficiency and product quality.

From an operational perspective, the MAF Glätter is designed to be user-friendly, thus transforming the industry standard for surface finishing tools. Its intuitive interface allows operators of varying skill levels to achieve optimal results without extensive training, favoring organizations seeking to maximize productivity and minimize operational costs. The adaptability of the MAF Glätter across different settings and requirements, as experienced by users globally, reinforces its standing as a versatile tool that every manufacturing unit should consider incorporating into their processes. Furthermore, the MAF Glätter is built with a commitment to safety and reliability, factors that enhance trust with users. Advanced safety protocols are embedded within its operation system, ensuring that even high-speed processing is conducted safely without compromising on quality. Such assurance is crucial for maintaining industry-standard safety protocols, gaining trust, and establishing long-term client relationships. The authoritative standing of the MAF Glätter is further underscored by its regulatory compliance with international standards, including ISO certifications. Such recognition not only legitimizes its market presence but also provides clients with confidence in their investment, knowing that they are acquiring equipment that is recognized and respected globally. Overall, the MAF Glätter is not just a surface finishing tool but a comprehensive solution that embodies innovation, expertise, and reliability. As manufacturing processes advance, tools like the MAF Glätter play an essential role in driving this forward by offering improved methodologies that save time, cut costs, and enhance product quality. Industries worldwide are moving towards more sustainable and efficient practices, and integrating the MAF Glätter into these processes serves as a testament to a company’s commitment to quality and innovation.

From an operational perspective, the MAF Glätter is designed to be user-friendly, thus transforming the industry standard for surface finishing tools. Its intuitive interface allows operators of varying skill levels to achieve optimal results without extensive training, favoring organizations seeking to maximize productivity and minimize operational costs. The adaptability of the MAF Glätter across different settings and requirements, as experienced by users globally, reinforces its standing as a versatile tool that every manufacturing unit should consider incorporating into their processes. Furthermore, the MAF Glätter is built with a commitment to safety and reliability, factors that enhance trust with users. Advanced safety protocols are embedded within its operation system, ensuring that even high-speed processing is conducted safely without compromising on quality. Such assurance is crucial for maintaining industry-standard safety protocols, gaining trust, and establishing long-term client relationships. The authoritative standing of the MAF Glätter is further underscored by its regulatory compliance with international standards, including ISO certifications. Such recognition not only legitimizes its market presence but also provides clients with confidence in their investment, knowing that they are acquiring equipment that is recognized and respected globally. Overall, the MAF Glätter is not just a surface finishing tool but a comprehensive solution that embodies innovation, expertise, and reliability. As manufacturing processes advance, tools like the MAF Glätter play an essential role in driving this forward by offering improved methodologies that save time, cut costs, and enhance product quality. Industries worldwide are moving towards more sustainable and efficient practices, and integrating the MAF Glätter into these processes serves as a testament to a company’s commitment to quality and innovation.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025