- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 06:59

Back to list

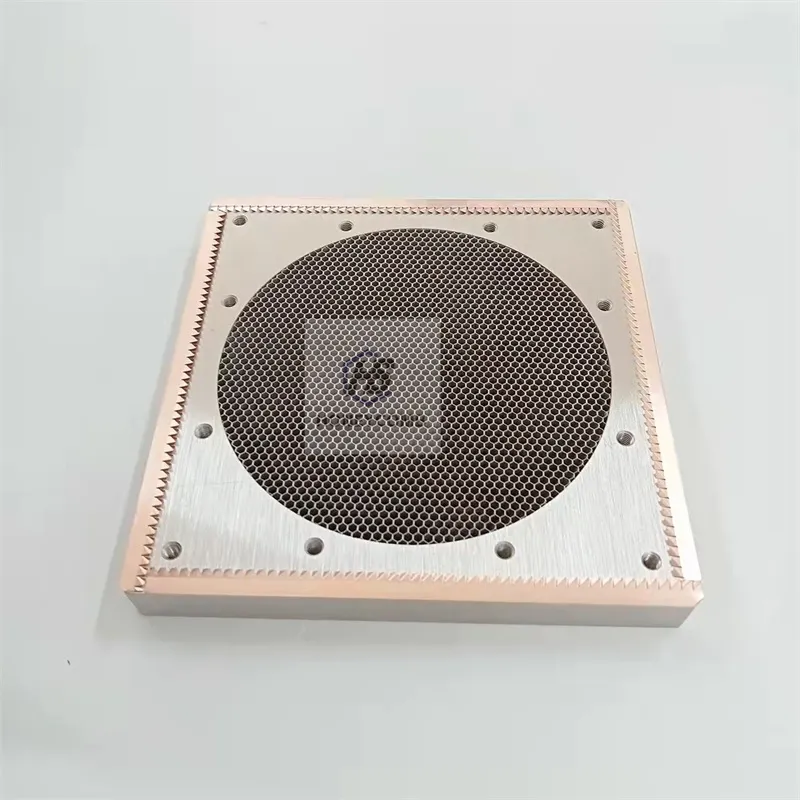

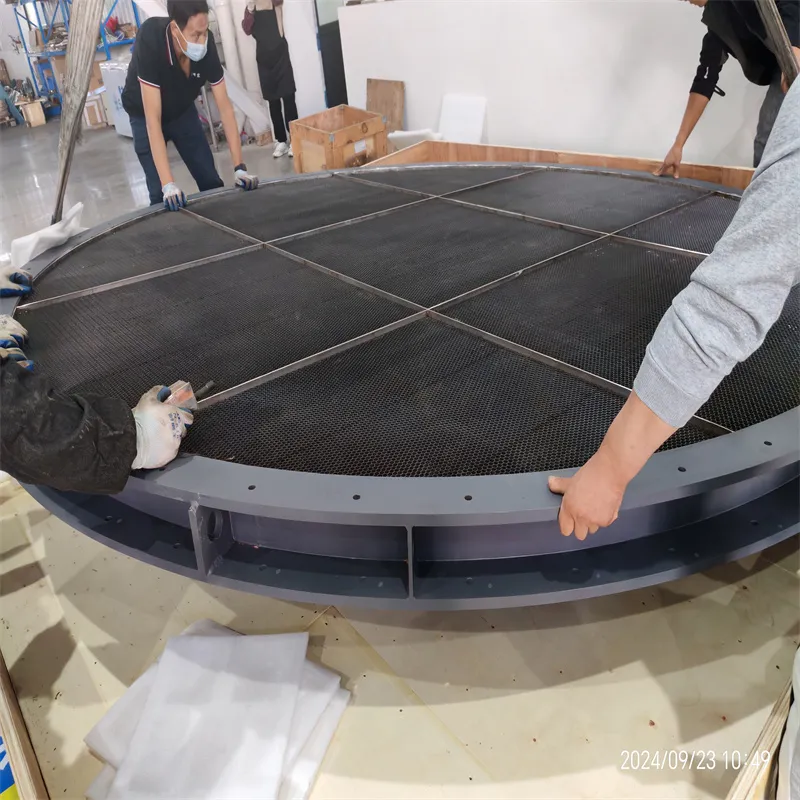

High Shielding Performance 2.0mm Cell Steel Honeycomb Vent For EMI/EMC/RF Shielded

In the vast landscape of modern industrial applications, airflow rectifiers, particularly those known as `luftstromgleichrichter` in parts of Europe, have emerged as pivotal components in the optimization and enhancement of air handling systems. Their significance is grounded in practical experience and backed by specialized expertise, making them an essential subject in the study of fluid dynamics and environmental engineering.

From a user’s perspective, the implementation of `luftstromgleichrichter` introduces tangible benefits in operational contexts. Simplified maintenance requirements and enhanced durability often result in reduced downtime and extended service life of air handling equipment. User testimonials and case studies across various industries reinforce these advantages, adding a layer of trustworthiness to the product’s reputation. Moreover, research studies contribute significantly to the body of knowledge surrounding these rectifiers. Academic publications often delve into cutting-edge developments in materials and design that can further optimize airflow rectifiers. Such research underscores the continuous innovation within the sector, underlining the commitment to enhancing product performance and efficiency. The future of `luftstromgleichrichter` lies in continued integration with smart technologies. As the world pivots towards IoT-enabled systems, the potential for these rectifiers to be part of automated and intelligent HVAC solutions grows. The capability to monitor and adjust airflow in real-time not only epitomizes technological advancement but also ensures that their application aligns with futuristic energy-saving goals. In summation, airflow rectifiers, or `luftstromgleichrichter`, represent a sophisticated intersection of engineering expertise, scientific rigor, and practical application. Their role in optimizing air handling systems is a testament to their design excellence and operational dependability. As industries continue to place premium value on efficiency and sustainability, the deployment of these rectifiers will remain integral. Their resonance within the domains of expertise and authoritativeness assures stakeholders of their pivotal role in enhancing system performance and operational reliability.

From a user’s perspective, the implementation of `luftstromgleichrichter` introduces tangible benefits in operational contexts. Simplified maintenance requirements and enhanced durability often result in reduced downtime and extended service life of air handling equipment. User testimonials and case studies across various industries reinforce these advantages, adding a layer of trustworthiness to the product’s reputation. Moreover, research studies contribute significantly to the body of knowledge surrounding these rectifiers. Academic publications often delve into cutting-edge developments in materials and design that can further optimize airflow rectifiers. Such research underscores the continuous innovation within the sector, underlining the commitment to enhancing product performance and efficiency. The future of `luftstromgleichrichter` lies in continued integration with smart technologies. As the world pivots towards IoT-enabled systems, the potential for these rectifiers to be part of automated and intelligent HVAC solutions grows. The capability to monitor and adjust airflow in real-time not only epitomizes technological advancement but also ensures that their application aligns with futuristic energy-saving goals. In summation, airflow rectifiers, or `luftstromgleichrichter`, represent a sophisticated intersection of engineering expertise, scientific rigor, and practical application. Their role in optimizing air handling systems is a testament to their design excellence and operational dependability. As industries continue to place premium value on efficiency and sustainability, the deployment of these rectifiers will remain integral. Their resonance within the domains of expertise and authoritativeness assures stakeholders of their pivotal role in enhancing system performance and operational reliability.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025