- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 06:41

Back to list

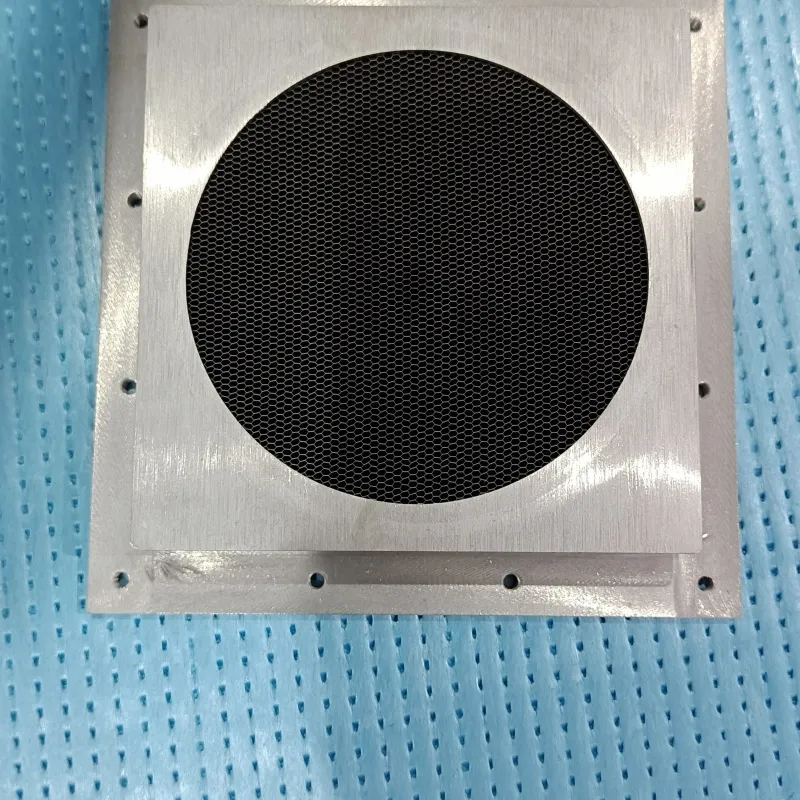

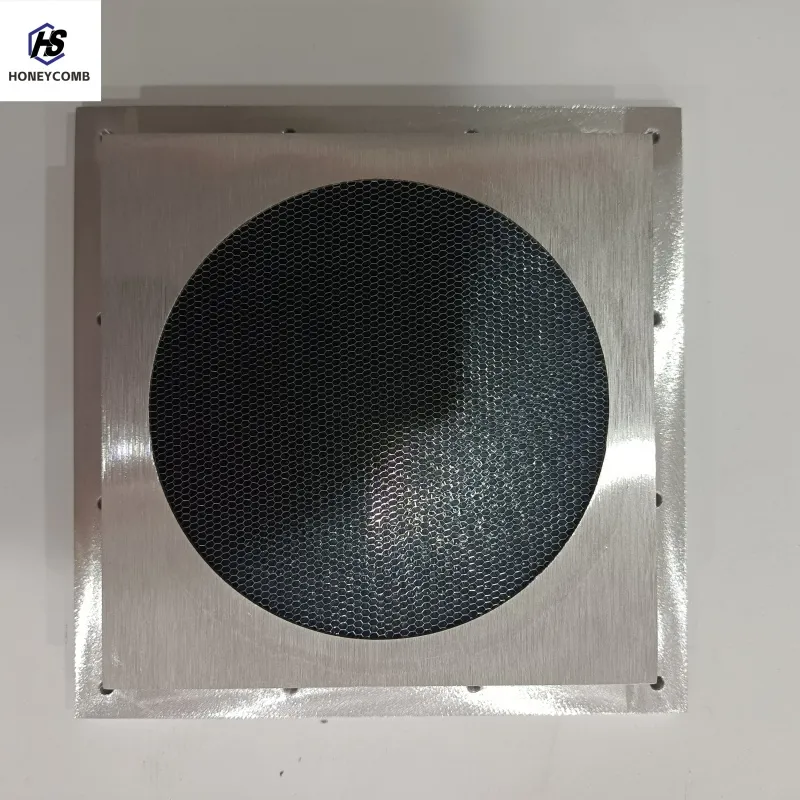

Honeycomb Stainless Steel Air Flow Straightener / Steel Honeycomb Wind Tunnel

In the increasingly complex world of electronics and engineering, the term Wabenluftstromgleichrichter might appear as an enigmatic phenomenon to many. However, for industry veterans and enthusiasts, it represents a groundbreaking advancement in air flow rectification technology. This article explores the Wabenluftstromgleichrichter with a keen focus on its practical applications, technical expertise, authoritative benefits, and the trustworthiness it has garnered across various sectors.

Trustworthiness is a key component of any cutting-edge technology, and Wabenluftstromgleichrichter does not fall short in delivering this assurance. Industry players who have integrated this system report consistent performance improvements and decreased operational costs. Testimonials from professionals in aerospace industries and climatology laboratories attest to the significant advancements achieved through these rectifiers. For businesses interested in adopting this technology, it’s crucial to understand the real-world experience of industries that have capitalized on its benefits. Take, for instance, a leading automotive manufacturer that incorporated Wabenluftstromgleichrichter into their cooling systems. The result was a marked improvement in engine efficiency, contributing to both reduced fuel consumption and emissions. Such case studies offer an authentic glimpse into the capability of this technology to transform industrial processes. In conclusion, as industries pivot towards sustainable and efficient technologies, the Wabenluftstromgleichrichter emerges as a frontrunner. Its design maximizes airflow efficiency, backed by scientific expertise and industry validation. Companies aiming to enhance their operational efficiency would find investing in such innovative solutions a step towards future-proofing their infrastructure. As more stakeholders embrace this technology, its role in propelling industries towards a greener and technologically advanced future becomes indisputable, driving both economic and environmental benefits across sectors globally.

Trustworthiness is a key component of any cutting-edge technology, and Wabenluftstromgleichrichter does not fall short in delivering this assurance. Industry players who have integrated this system report consistent performance improvements and decreased operational costs. Testimonials from professionals in aerospace industries and climatology laboratories attest to the significant advancements achieved through these rectifiers. For businesses interested in adopting this technology, it’s crucial to understand the real-world experience of industries that have capitalized on its benefits. Take, for instance, a leading automotive manufacturer that incorporated Wabenluftstromgleichrichter into their cooling systems. The result was a marked improvement in engine efficiency, contributing to both reduced fuel consumption and emissions. Such case studies offer an authentic glimpse into the capability of this technology to transform industrial processes. In conclusion, as industries pivot towards sustainable and efficient technologies, the Wabenluftstromgleichrichter emerges as a frontrunner. Its design maximizes airflow efficiency, backed by scientific expertise and industry validation. Companies aiming to enhance their operational efficiency would find investing in such innovative solutions a step towards future-proofing their infrastructure. As more stakeholders embrace this technology, its role in propelling industries towards a greener and technologically advanced future becomes indisputable, driving both economic and environmental benefits across sectors globally.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025