- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 13:17

Back to list

maf straightener

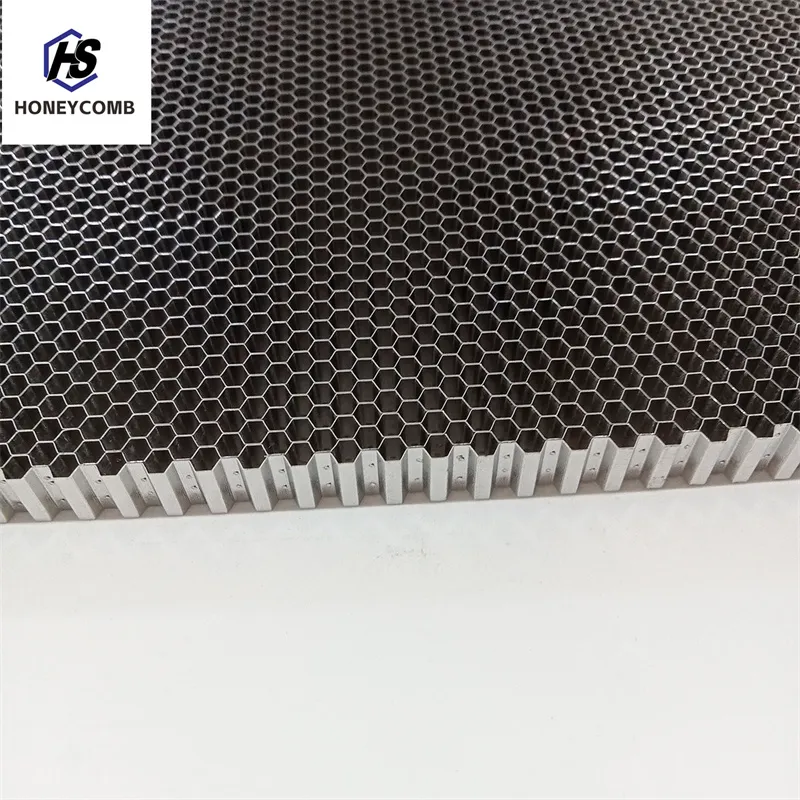

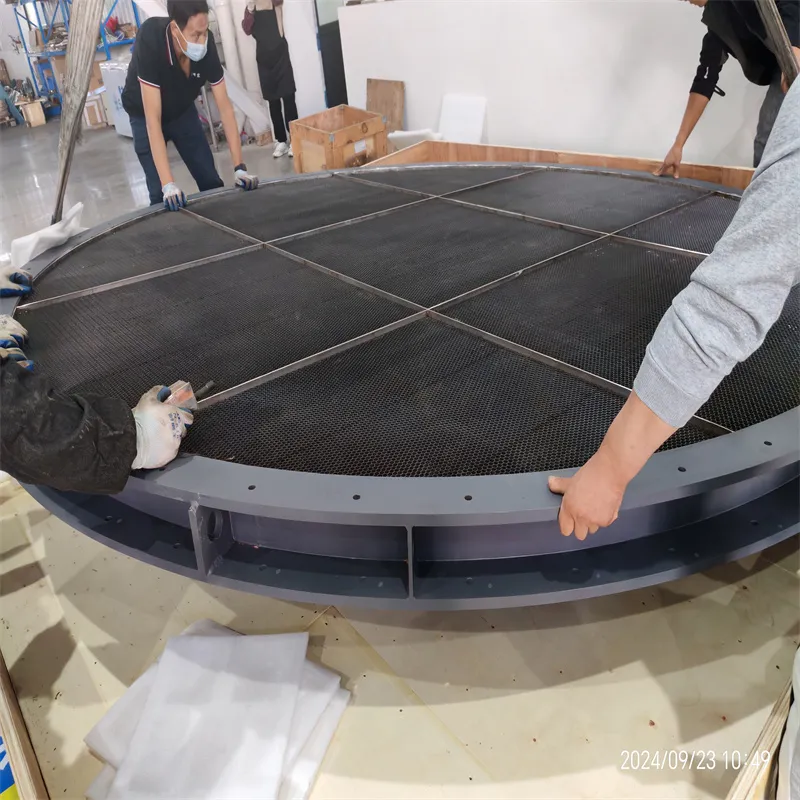

Aluminum honeycomb panels have gained immense popularity in recent years due to their numerous applications in various industries. These panels are lightweight, strong, and have remarkable compressive strength, making them ideal for both structural and decorative purposes. The use of aluminum honeycomb sheets is particularly noteworthy in sectors such as aerospace, automotive, and construction, where material reliability and performance are paramount.

The authoritative aspect of aluminum honeycomb panels is backed by rigorous testing and certifications. Manufacturers adhere to stringent international standards, ensuring the panels meet safety and performance criteria. Institutions like the American Society for Testing and Materials (ASTM) provide guidelines that verify the panels' capabilities under various environmental conditions. This assurance is critical for stakeholders who prioritize safety and durability. Trustworthiness of aluminum honeycomb technology is also reinforced by numerous positive testimonials from industry veterans and satisfied clients. Companies in the automotive sector have reported significant advancements in vehicle design, attributing success to the lightweight and durable nature of these panels. Collaborative projects between manufacturers and automotive giants showcase the panels' contribution to innovation in sustainable transportation solutions. In summary, the utilization of aluminum honeycomb panels presents a compelling case in modern engineering and architecture. The myriad benefits—from energy savings and cost-effectiveness to design flexibility and environmental impact—make these panels a worthy consideration for contemporary construction and manufacturing challenges. Trust in this advanced material continues to grow as more sectors recognize and validate its transformative potential. Embracing aluminum honeycomb not only represents a step forward in material science but also a commitment to sustainability and efficiency.

The authoritative aspect of aluminum honeycomb panels is backed by rigorous testing and certifications. Manufacturers adhere to stringent international standards, ensuring the panels meet safety and performance criteria. Institutions like the American Society for Testing and Materials (ASTM) provide guidelines that verify the panels' capabilities under various environmental conditions. This assurance is critical for stakeholders who prioritize safety and durability. Trustworthiness of aluminum honeycomb technology is also reinforced by numerous positive testimonials from industry veterans and satisfied clients. Companies in the automotive sector have reported significant advancements in vehicle design, attributing success to the lightweight and durable nature of these panels. Collaborative projects between manufacturers and automotive giants showcase the panels' contribution to innovation in sustainable transportation solutions. In summary, the utilization of aluminum honeycomb panels presents a compelling case in modern engineering and architecture. The myriad benefits—from energy savings and cost-effectiveness to design flexibility and environmental impact—make these panels a worthy consideration for contemporary construction and manufacturing challenges. Trust in this advanced material continues to grow as more sectors recognize and validate its transformative potential. Embracing aluminum honeycomb not only represents a step forward in material science but also a commitment to sustainability and efficiency.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025