- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 13:32

Back to list

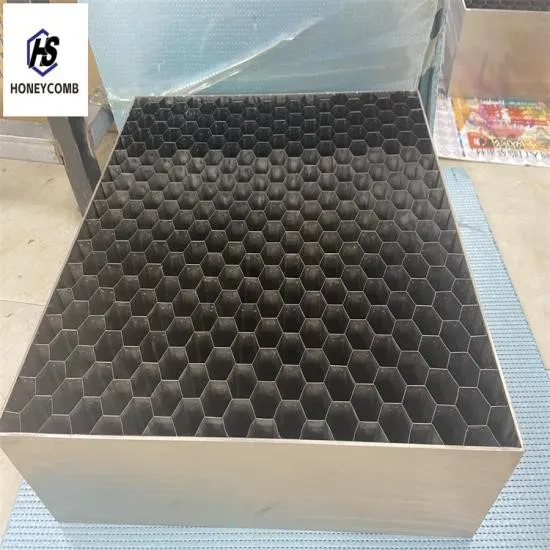

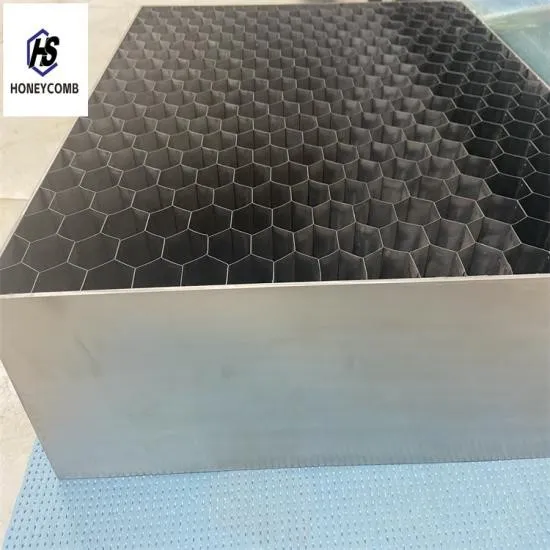

Revolutionize Your wind tunnel testing with precision Honeycomb cells ultimate aerodynamic Efficiency

The cellular marvel of the perforated honeycomb core holds the potential to redefine industries with its unique blend of strength and versatility. Initially mimicked from nature's own engineering genius—the honeycomb, these cores are becoming increasingly integral across multiple sectors such as aerospace, construction, and mechanical engineering.

From an expertise perspective, the lifecycle performance of perforated honeycomb cores is impressive. Their resistance to corrosion, coupled with stability under thermal and mechanical stress, extends their lifespan significantly when compared to traditional solid materials. Industry researchers underscore the relatively low maintenance and replacement costs associated with these cores, making them not only an advanced choice but also an economical one over time. Furthermore, the environmental benefits cannot be overstated. Producing these cores involves less material than equivalent solid structures, reducing resource extraction and waste. When composed of recyclable metals or composites, their environmental footprint diminishes even further. Sustainability experts advocate for their use pointing out how they align well with green building standards and contribute positively to a circular economy. Trust in perforated honeycomb core technology is supported by a growing body of validation. Extensive industry testing and case studies confirm their performance benefits. Manufacturing companies with ISO certifications ensure stringent quality control, enhancing reliability and consistency in product output. End-users can entrust these cores to consistently meet high performance and safety standards, safeguarding both investments and operational objectives. As the industrial landscape continues to evolve, perforated honeycomb cores are positioned at the leading edge of material innovation. They embody a synergy of nature’s ingenuity and cutting-edge manufacturing, offering newer pathways for engineers, builders, and designers to explore and expand. In a world continually pushing towards sustainability without sacrificing performance, the perforated honeycomb core stands as a testament to what can be achieved when humanity takes cues from the natural world.

From an expertise perspective, the lifecycle performance of perforated honeycomb cores is impressive. Their resistance to corrosion, coupled with stability under thermal and mechanical stress, extends their lifespan significantly when compared to traditional solid materials. Industry researchers underscore the relatively low maintenance and replacement costs associated with these cores, making them not only an advanced choice but also an economical one over time. Furthermore, the environmental benefits cannot be overstated. Producing these cores involves less material than equivalent solid structures, reducing resource extraction and waste. When composed of recyclable metals or composites, their environmental footprint diminishes even further. Sustainability experts advocate for their use pointing out how they align well with green building standards and contribute positively to a circular economy. Trust in perforated honeycomb core technology is supported by a growing body of validation. Extensive industry testing and case studies confirm their performance benefits. Manufacturing companies with ISO certifications ensure stringent quality control, enhancing reliability and consistency in product output. End-users can entrust these cores to consistently meet high performance and safety standards, safeguarding both investments and operational objectives. As the industrial landscape continues to evolve, perforated honeycomb cores are positioned at the leading edge of material innovation. They embody a synergy of nature’s ingenuity and cutting-edge manufacturing, offering newer pathways for engineers, builders, and designers to explore and expand. In a world continually pushing towards sustainability without sacrificing performance, the perforated honeycomb core stands as a testament to what can be achieved when humanity takes cues from the natural world.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025