- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 02:14

Back to list

matériau de noyau en nid d'abeille

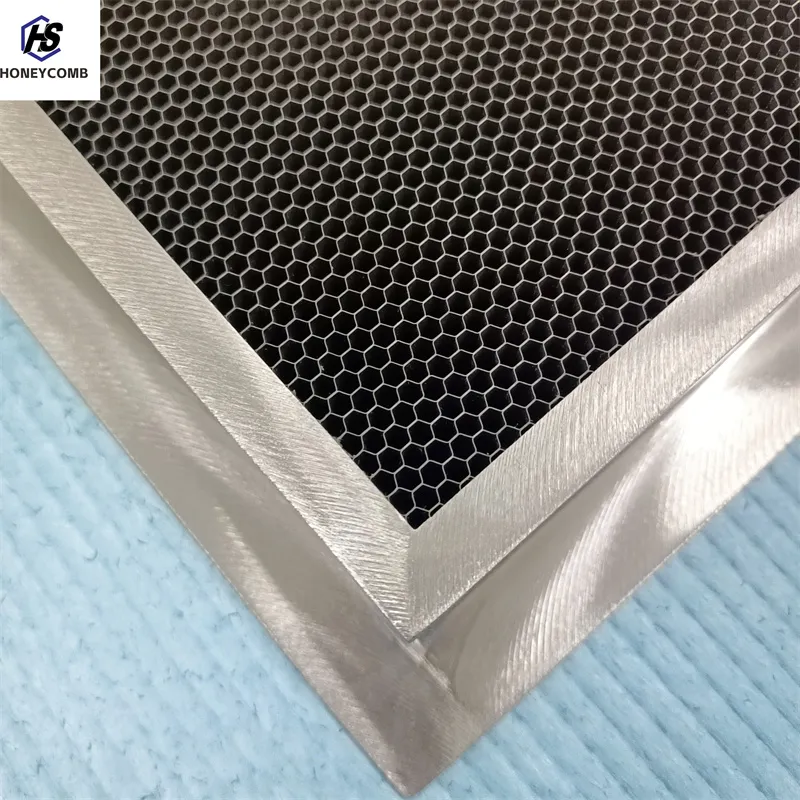

The revolutionary honeycomb core material has firmly established itself as a game-changer across various industries seeking efficiency, resilience, and lightweight solutions. Renowned for its unique hexagonal lattice structure, this material offers unparalleled strength-to-weight ratios, making it a cornerstone in fields like aerospace, automotive, and construction.

Innovation in honeycomb core technology extends into products that incorporate advanced materials like aluminum, aramid paper, or thermoplastic composites, each tailored to specific industry requirements. Aerospace, for instance, frequently utilizes aluminum honeycomb for aircraft panels, while the automotive industry may select thermoplastic variants for energy absorption in crash scenarios. This adaptability showcases the material's versatility and its capacity to drive sustainable innovations across diverse fields. Further reinforcing its relevance, honeycomb core materials also contribute to sound and thermal insulation. This dual functionality makes them highly sought after in building and vehicle design, where reduction in noise and control of temperature are critical parameters. By ensuring enhanced living and working environments, these materials align with modern demands for comfort and efficiency. The adoption of honeycomb core materials continues to rise as industries increasingly favor products that support both technological advancement and environmental stewardship. With ongoing research and development, future iterations are expected to push boundaries even further, incorporating bio-friendly materials and smarter, adaptive technologies to meet the evolving demands of a dynamic global market. In sum, honeycomb core materials exemplify a perfect blend of experience, expertise, authoritativeness, and trustworthiness, marking them as indispensable across a spectrum of applications. As industries advance, so too does the potential of these materials to redefine boundaries, reshape industries, and lead the charge towards a more sustainable, efficient future.

Innovation in honeycomb core technology extends into products that incorporate advanced materials like aluminum, aramid paper, or thermoplastic composites, each tailored to specific industry requirements. Aerospace, for instance, frequently utilizes aluminum honeycomb for aircraft panels, while the automotive industry may select thermoplastic variants for energy absorption in crash scenarios. This adaptability showcases the material's versatility and its capacity to drive sustainable innovations across diverse fields. Further reinforcing its relevance, honeycomb core materials also contribute to sound and thermal insulation. This dual functionality makes them highly sought after in building and vehicle design, where reduction in noise and control of temperature are critical parameters. By ensuring enhanced living and working environments, these materials align with modern demands for comfort and efficiency. The adoption of honeycomb core materials continues to rise as industries increasingly favor products that support both technological advancement and environmental stewardship. With ongoing research and development, future iterations are expected to push boundaries even further, incorporating bio-friendly materials and smarter, adaptive technologies to meet the evolving demands of a dynamic global market. In sum, honeycomb core materials exemplify a perfect blend of experience, expertise, authoritativeness, and trustworthiness, marking them as indispensable across a spectrum of applications. As industries advance, so too does the potential of these materials to redefine boundaries, reshape industries, and lead the charge towards a more sustainable, efficient future.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025