- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 02:32

Back to list

nid d'abeille aérospatiale

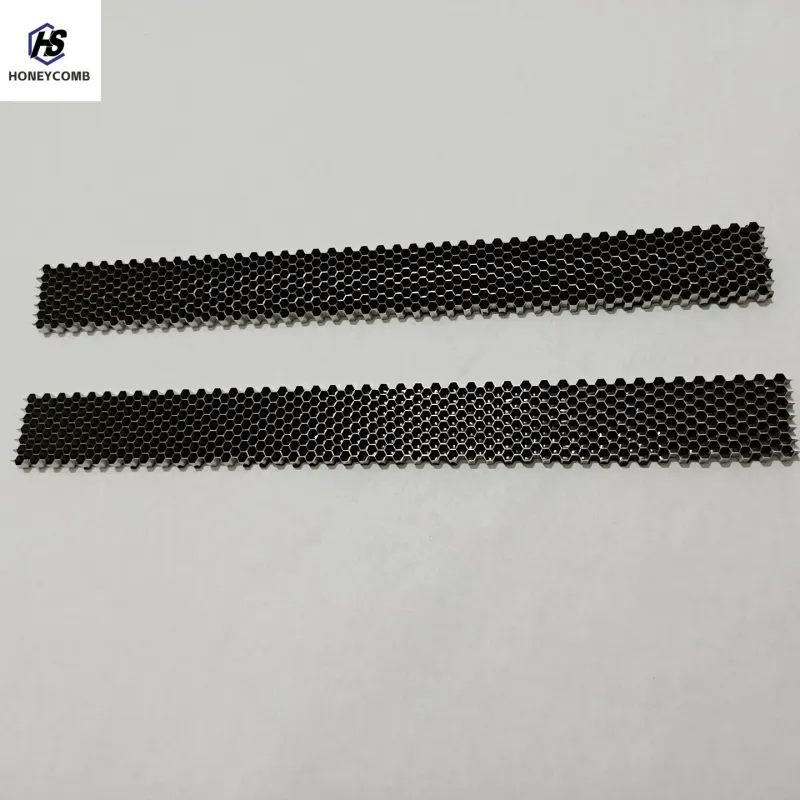

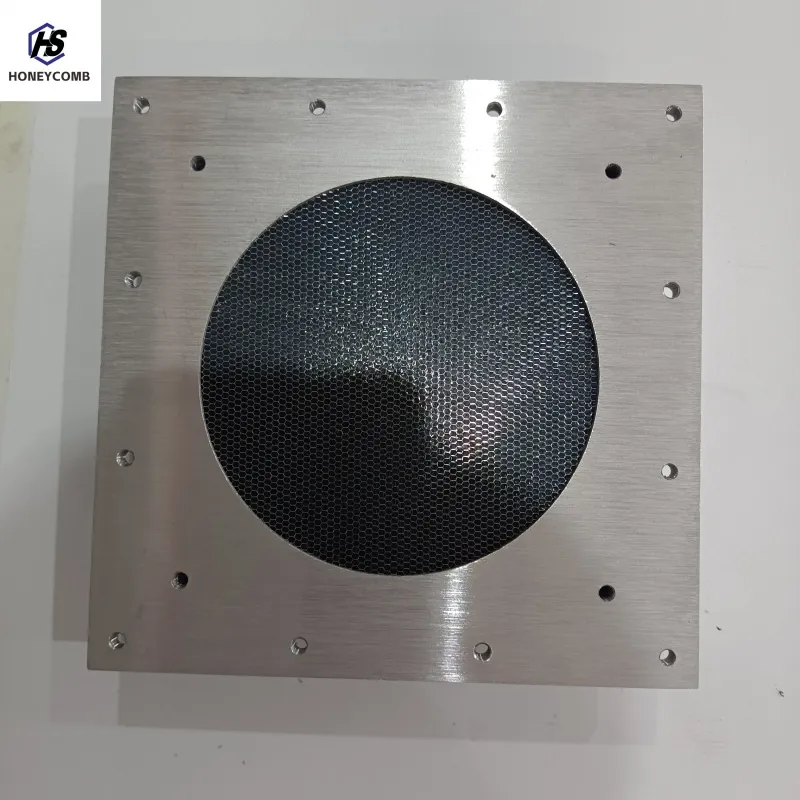

Aspiring aerospace enthusiasts and professionals often seek reliable and accurate information on innovative technologies. One such intriguing term that may surface during your exploration is nid d'abeille aérospatiale, or aerospace honeycomb structure. Its marked significance in aeronautics and space exploration stems from its unique attributes inspired by nature itself.

In the manufacturing realm, expertise in producing these materials is vital. Numerous companies specialize in the development and refinement of honeycomb panels and cores. Such expertise provides assurance in quality, adherence to strict aerospace standards, and customization to specified requirements of leading aerospace manufacturers. Yet, the successful integration and application of these structures depend significantly on the expertness of aeronautics professionals and materials scientists. Their continuous research and development enhance these solutions, making them more adaptable, sustainable, and efficient for future aerospace advancements. Authoritativeness in this domain is strengthened by renowned institutions and governmental bodies dedicated to aerospace technology. They play critical roles not only in regulation aspects but also in advancing research initiatives that keep pushing the boundaries of what engineered honeycomb structures can achieve. Trustworthiness intersects with the stringent certification processes required for materials and components deployed in aeronautics. This ensures that every element meets exhaustive safety and performance criteria, chosen only after meticulous evaluation and testing. For individuals or entities invested in this sector, understanding the intricacies and innovations surrounding honeycomb structures is crucial. Staying abreast of material advancements, evolving engineering techniques, and regulatory shifts offers a competitive edge. In essence, aerospace honeycomb structure (nid d'abeille aérospatiale) embodies a vital confluence of nature-inspired design and cutting-edge engineering. The capability to revolutionize structural efficiency while maintaining rigorous safety and performance standards marks it as a cornerstone technology in contemporary and future aerospace applications. Whether you are an industry expert, budding engineer, or technology enthusiast, the wise application and understanding of this structure guarantee a robust foundation for aerospace innovation and exploration.

In the manufacturing realm, expertise in producing these materials is vital. Numerous companies specialize in the development and refinement of honeycomb panels and cores. Such expertise provides assurance in quality, adherence to strict aerospace standards, and customization to specified requirements of leading aerospace manufacturers. Yet, the successful integration and application of these structures depend significantly on the expertness of aeronautics professionals and materials scientists. Their continuous research and development enhance these solutions, making them more adaptable, sustainable, and efficient for future aerospace advancements. Authoritativeness in this domain is strengthened by renowned institutions and governmental bodies dedicated to aerospace technology. They play critical roles not only in regulation aspects but also in advancing research initiatives that keep pushing the boundaries of what engineered honeycomb structures can achieve. Trustworthiness intersects with the stringent certification processes required for materials and components deployed in aeronautics. This ensures that every element meets exhaustive safety and performance criteria, chosen only after meticulous evaluation and testing. For individuals or entities invested in this sector, understanding the intricacies and innovations surrounding honeycomb structures is crucial. Staying abreast of material advancements, evolving engineering techniques, and regulatory shifts offers a competitive edge. In essence, aerospace honeycomb structure (nid d'abeille aérospatiale) embodies a vital confluence of nature-inspired design and cutting-edge engineering. The capability to revolutionize structural efficiency while maintaining rigorous safety and performance standards marks it as a cornerstone technology in contemporary and future aerospace applications. Whether you are an industry expert, budding engineer, or technology enthusiast, the wise application and understanding of this structure guarantee a robust foundation for aerospace innovation and exploration.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025