- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 08, 2025 04:58

Back to list

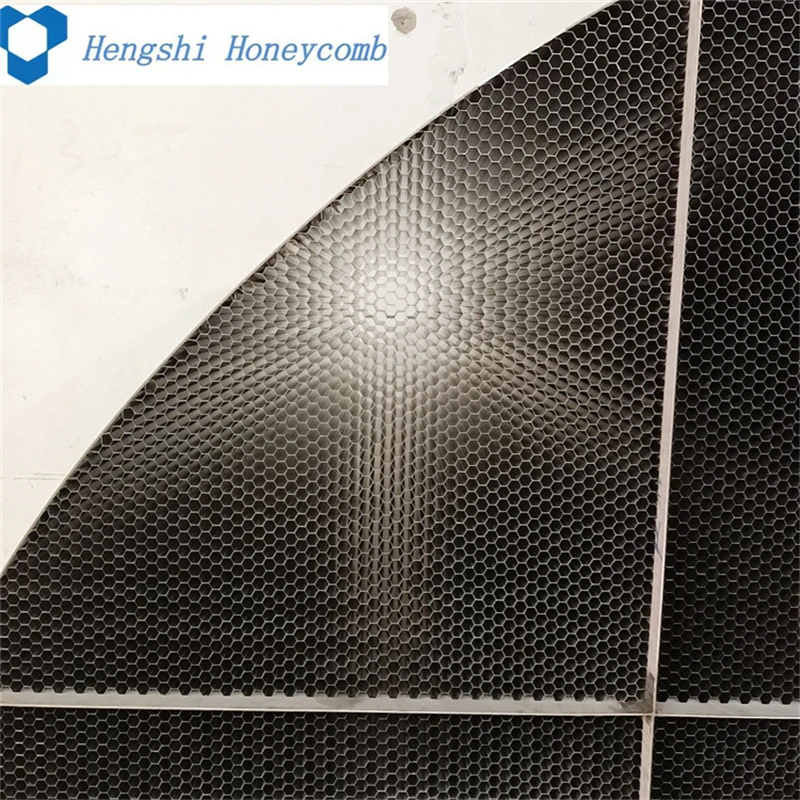

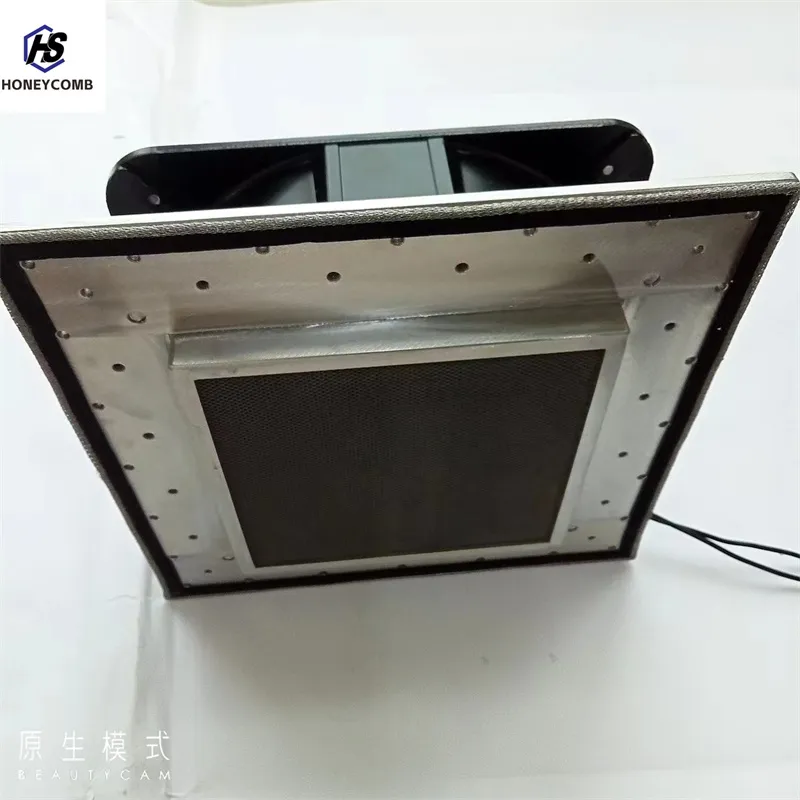

maf honeycomb screen

Metallic honeycombs have emerged as a transformative material in various industries, offering a unique blend of strength, lightness, and versatility. Their structure is inspired by nature, mimicking the efficient and resilient design of natural honeycombs, which provides remarkable mechanical properties tailored for a variety of applications.

The expertise involved in manufacturing metallic honeycombs also extends to their corrosion resistance and longevity, which are crucial for their use in various environments, from marine to industrial settings. Engineers employ special coatings and alloys that enhance the natural durability of metallic honeycombs. This extends their lifespan in corrosive environments, offering a cost-effective solution over time. End-users have reported positive experiences and substantial cost and performance benefits when incorporating metallic honeycomb products into their structures and systems. This level of experience satisfaction contributes to the growing trust in metallic honeycombs and solidifies their place as an authoritative choice for engineering and design solutions. Each advancement and adaptation of metallic honeycombs reinforce their position as a pivotal material in sustainable development. By harnessing the durability and recyclability of metals, alongside their inherent design efficiencies, industries are increasingly relying on metallic honeycombs to drive innovation with a reduced environmental footprint. In sum, the capability of metallic honeycombs to combine robustness and lightweight characteristics makes them indispensable in high-performance applications across multiple sectors. They embody the core principles of modern engineering maximizing performance, minimizing waste, and pushing the frontier of what materials science can achieve. The continuous research and development in this field are bound to further enhance their applicability and effectiveness, maintaining their status as a trustworthy and authoritative material in both current and future technological landscapes.

The expertise involved in manufacturing metallic honeycombs also extends to their corrosion resistance and longevity, which are crucial for their use in various environments, from marine to industrial settings. Engineers employ special coatings and alloys that enhance the natural durability of metallic honeycombs. This extends their lifespan in corrosive environments, offering a cost-effective solution over time. End-users have reported positive experiences and substantial cost and performance benefits when incorporating metallic honeycomb products into their structures and systems. This level of experience satisfaction contributes to the growing trust in metallic honeycombs and solidifies their place as an authoritative choice for engineering and design solutions. Each advancement and adaptation of metallic honeycombs reinforce their position as a pivotal material in sustainable development. By harnessing the durability and recyclability of metals, alongside their inherent design efficiencies, industries are increasingly relying on metallic honeycombs to drive innovation with a reduced environmental footprint. In sum, the capability of metallic honeycombs to combine robustness and lightweight characteristics makes them indispensable in high-performance applications across multiple sectors. They embody the core principles of modern engineering maximizing performance, minimizing waste, and pushing the frontier of what materials science can achieve. The continuous research and development in this field are bound to further enhance their applicability and effectiveness, maintaining their status as a trustworthy and authoritative material in both current and future technological landscapes.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025