- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 08, 2025 04:34

Back to list

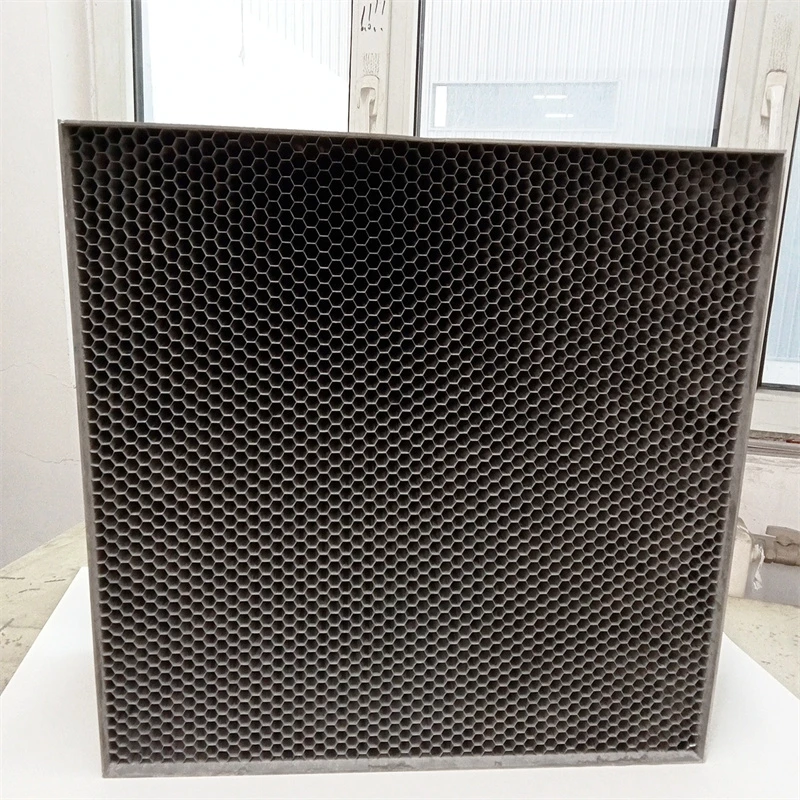

honeycomb core steel door

Metal honeycomb cores are revolutionizing the way industries think about structural integrity, reducing weight without sacrificing strength. Widely recognized for their lightweight and robust architecture, these materials are becoming the backbone of multiple applications across automotive, aerospace, and construction industries.

Despite the myriad advantages, implementing metal honeycomb cores does require expert understanding and precise manufacturing techniques. Dependable performance depends on the meticulous selection of materials, such as aluminum or titanium, each contributing specific benefits. Aluminum stands out for its corrosion resistance and flexibility, making it suitable for general applications. Titanium, although costlier, is prized for its high strength and low thermal expansion, making it indispensable for high-performance and critical applications like aerospace. Given the complex demands of industries using this technology, the role of trust and expertise cannot be overstated. Businesses choosing to implement metal honeycomb core solutions must rely on manufacturers with proven experience and a track record of reliability. These manufacturers should have rigorous testing protocols and adhere to industry standards to ensure that all products meet or exceed performance requirements. A critical facet of trustworthiness in this sector is transparency in the sourcing of raw materials and the sustainability of manufacturing processes. Companies that prioritize environmental responsibility reassure their clients of not only the quality of the metal honeycomb cores but also their ethical commitment to reducing their ecological footprint. This aspect is becoming increasingly important as businesses and consumers alike demand products that align with sustainability principles. Additionally, real-world case studies and user testimonials provide indispensable insights into the capabilities of metal honeycomb cores, proving their value in demanding environments. These firsthand accounts from engineers and architects underscore the practicality and effectiveness of metal honeycomb solutions, fostering confidence in their application. In conclusion, metal honeycomb cores represent an optimal fusion of nature-inspired design and advanced engineering, offering a versatile solution for a variety of industrial challenges. Their unique properties enable industries to meet stringent performance, safety, and environmental targets. As technology advances, the continuous development of metal honeycomb cores promises to unlock new possibilities and further establish their place as a crucial material in the modern engineering toolkit.

Despite the myriad advantages, implementing metal honeycomb cores does require expert understanding and precise manufacturing techniques. Dependable performance depends on the meticulous selection of materials, such as aluminum or titanium, each contributing specific benefits. Aluminum stands out for its corrosion resistance and flexibility, making it suitable for general applications. Titanium, although costlier, is prized for its high strength and low thermal expansion, making it indispensable for high-performance and critical applications like aerospace. Given the complex demands of industries using this technology, the role of trust and expertise cannot be overstated. Businesses choosing to implement metal honeycomb core solutions must rely on manufacturers with proven experience and a track record of reliability. These manufacturers should have rigorous testing protocols and adhere to industry standards to ensure that all products meet or exceed performance requirements. A critical facet of trustworthiness in this sector is transparency in the sourcing of raw materials and the sustainability of manufacturing processes. Companies that prioritize environmental responsibility reassure their clients of not only the quality of the metal honeycomb cores but also their ethical commitment to reducing their ecological footprint. This aspect is becoming increasingly important as businesses and consumers alike demand products that align with sustainability principles. Additionally, real-world case studies and user testimonials provide indispensable insights into the capabilities of metal honeycomb cores, proving their value in demanding environments. These firsthand accounts from engineers and architects underscore the practicality and effectiveness of metal honeycomb solutions, fostering confidence in their application. In conclusion, metal honeycomb cores represent an optimal fusion of nature-inspired design and advanced engineering, offering a versatile solution for a variety of industrial challenges. Their unique properties enable industries to meet stringent performance, safety, and environmental targets. As technology advances, the continuous development of metal honeycomb cores promises to unlock new possibilities and further establish their place as a crucial material in the modern engineering toolkit.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025