- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 03:15

Back to list

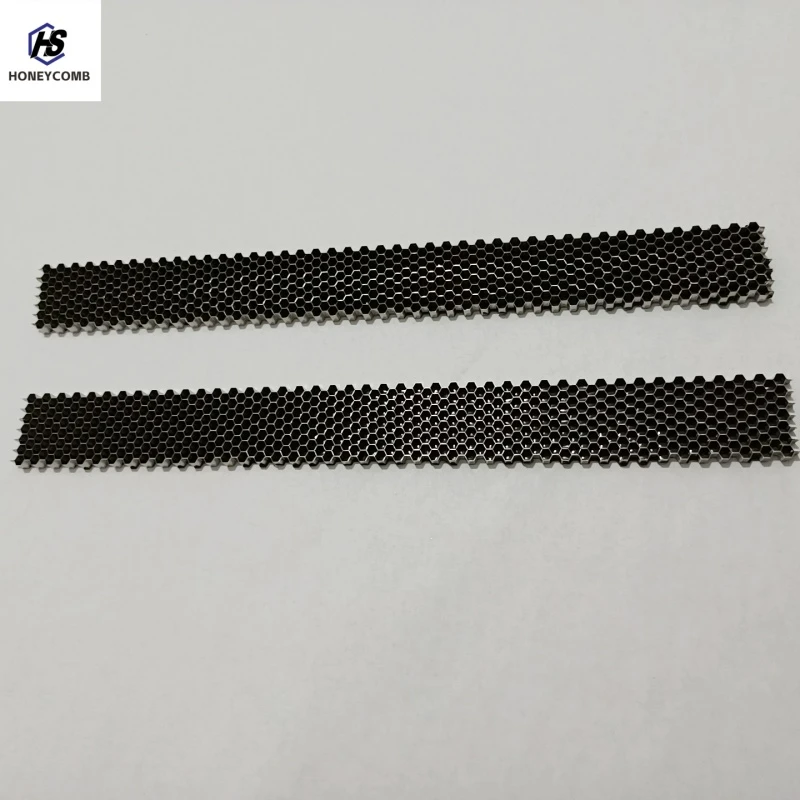

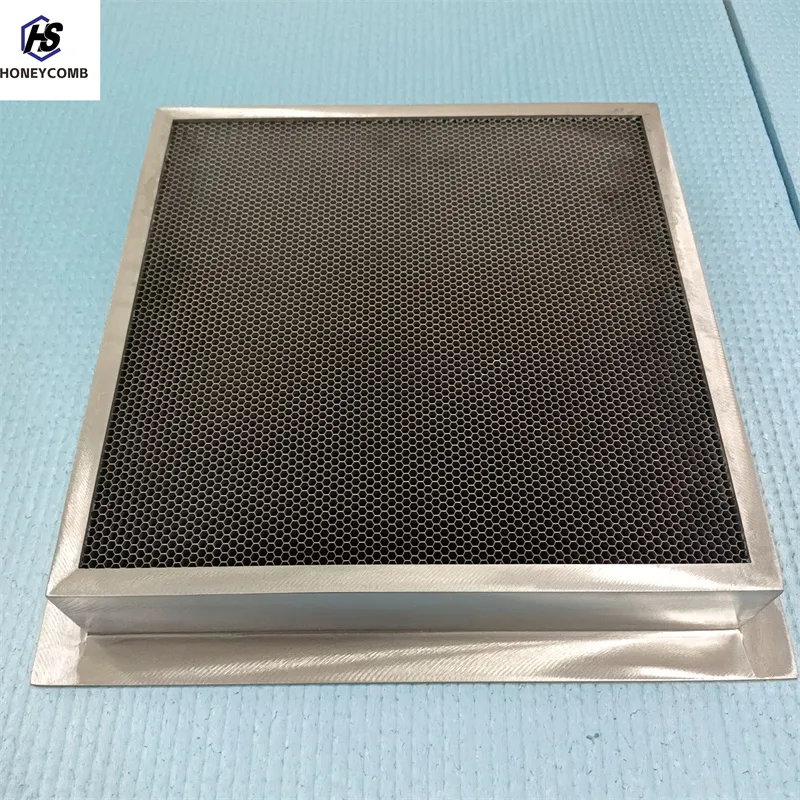

Filter Straightener Widely Used in Various Flow Field Wind Tunnel Water Tunnel for Testing Design

Aluminum 5052 honeycomb core has rapidly become a cornerstone in various industries due to its remarkable combination of strength, lightweight properties, and durability. Recognized for enhancing product performance in applications ranging from aerospace to architecture, the expertise surrounding its use continues to grow. Through a professional lens, examining the key benefits, uses, and innovations involving this material underscores its authoritative position in modern engineering solutions.

Advancements in manufacturing processes continually enhance the capabilities of aluminum 5052 honeycomb products. With innovative fabrication techniques, professionals now create bespoke solutions tailored to specific requirements, from customized panel sizes to varying core densities. This expertise enables manufacturers to deliver ultra-precise components tailored for specialized applications, further solidifying the material's standing as a reliable resource. Sustainability is another essential aspect, as aluminum 5052 honeycomb cores are fully recyclable. Industry leaders in sustainability initiatives advocate for using such materials due to their reduced environmental impact and contribution to the circular economy. The ability to recycle these products without loss of performance characteristics adds a significant dimension of trustworthiness in using aluminum honeycomb cores as a forward-thinking, eco-conscious choice. Professionals engaged in the research and development of aluminum honeycomb structures emphasize the material's adaptability in emerging technologies, such as unmanned aerial vehicles (UAVs) and electric vehicles (EVs). The continuous collaborative efforts between industry veterans and research institutions drive innovations that expand the potential applications of aluminum honeycomb technology. In conclusion, the aluminum 5052 honeycomb core is more than just a material; it represents an intersection of engineering prowess, environmental consideration, and versatile utility. Its ongoing evolution and the expertise developed around its use reinforce its position as a critical component in diverse industries. As technologies and requirements evolve, the unique properties and enhancements of this material promise to keep it at the forefront of engineering solutions, offering a trustworthy and authoritative option for future innovations.

Advancements in manufacturing processes continually enhance the capabilities of aluminum 5052 honeycomb products. With innovative fabrication techniques, professionals now create bespoke solutions tailored to specific requirements, from customized panel sizes to varying core densities. This expertise enables manufacturers to deliver ultra-precise components tailored for specialized applications, further solidifying the material's standing as a reliable resource. Sustainability is another essential aspect, as aluminum 5052 honeycomb cores are fully recyclable. Industry leaders in sustainability initiatives advocate for using such materials due to their reduced environmental impact and contribution to the circular economy. The ability to recycle these products without loss of performance characteristics adds a significant dimension of trustworthiness in using aluminum honeycomb cores as a forward-thinking, eco-conscious choice. Professionals engaged in the research and development of aluminum honeycomb structures emphasize the material's adaptability in emerging technologies, such as unmanned aerial vehicles (UAVs) and electric vehicles (EVs). The continuous collaborative efforts between industry veterans and research institutions drive innovations that expand the potential applications of aluminum honeycomb technology. In conclusion, the aluminum 5052 honeycomb core is more than just a material; it represents an intersection of engineering prowess, environmental consideration, and versatile utility. Its ongoing evolution and the expertise developed around its use reinforce its position as a critical component in diverse industries. As technologies and requirements evolve, the unique properties and enhancements of this material promise to keep it at the forefront of engineering solutions, offering a trustworthy and authoritative option for future innovations.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025