- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 28, 2025 04:06

Back to list

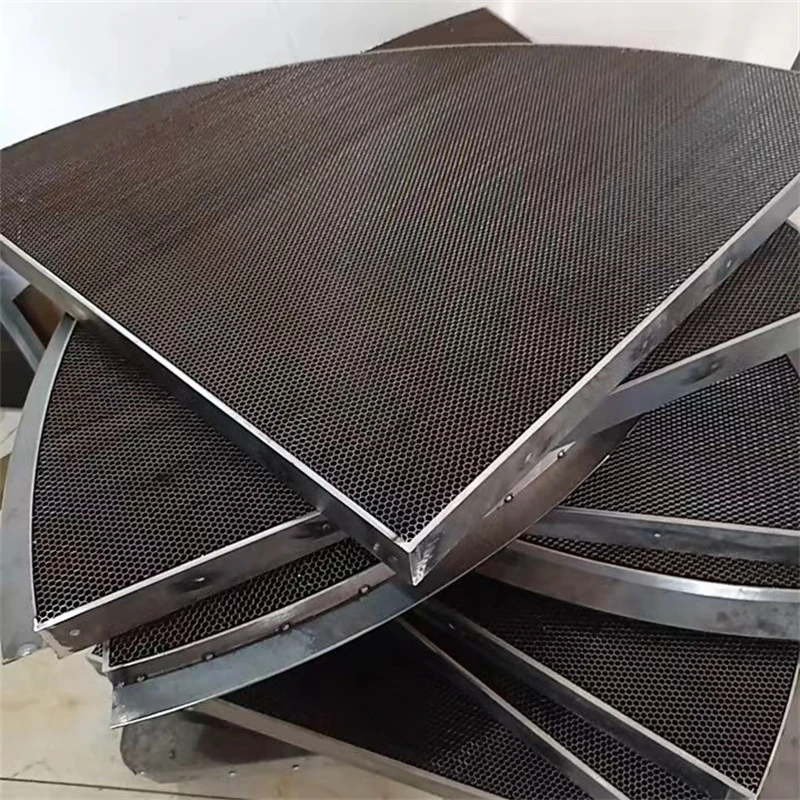

intake air straightener

Stainless steel honeycomb panels are revolutionizing industries ranging from aerospace to architecture, with their remarkable combination of strength, lightweight properties, and corrosion resistance. These panels are not merely a part of modern engineering; they represent a leap forward in material science, bringing benefits that are transforming both design and functionality worldwide.

This burgeoning sector owes its reliability and performance capacities to rigorous testing and quality assurance processes. Panels undergo thorough mechanical testing to assess their resistance to impact, pressure, and fatigue. They are subjected to environmental simulations that test their resilience against various weather conditions, ensuring their applicability in any climate. Such stringent evaluations foster trust among consumers and businesses that require absolute dependability from the materials they choose. Trustworthiness is further reinforced through industry certifications. Leaders in stainless steel honeycomb panel manufacturing consistently acquire certifications from recognized global standards organizations, reflecting their commitment to quality and excellence. This achievement not only strengthens their reputation but also provides consumers with confidence that the products adhere to international safety and performance criteria. Moreover, the environmental impact plays a crucial role in the rising popularity of stainless steel honeycomb panels. Given the current global push towards sustainable practices, the material's recyclability makes it an attractive option for environmentally conscious projects. The panels can be fully recycled at the end of their life cycle, minimizing waste and contributing positively to green building practices. Professionals working with stainless steel honeycomb panels often highlight the blend of expertise and innovation involved in their deployment. Engineers and architects who incorporate these panels into their projects enjoy a sense of authority, able to leverage cutting-edge technology to deliver top-notch results. Their utilization is a testament to how interdisciplinary collaboration between science and creativity can produce superior construction outcomes. In summary, stainless steel honeycomb panels are setting new milestones in various industries through their impeccable design and unrivaled performance. As more industries discover their potential, these panels will surely grow in demand, continuously reshaping the landscapes of modern engineering and design. Whether it's enhancing the fuel efficiency of an aircraft or the longevity of a maritime vessel, these innovative panels are proving to be indispensable assets in a world increasingly focused on efficiency, reliability, and sustainability.

This burgeoning sector owes its reliability and performance capacities to rigorous testing and quality assurance processes. Panels undergo thorough mechanical testing to assess their resistance to impact, pressure, and fatigue. They are subjected to environmental simulations that test their resilience against various weather conditions, ensuring their applicability in any climate. Such stringent evaluations foster trust among consumers and businesses that require absolute dependability from the materials they choose. Trustworthiness is further reinforced through industry certifications. Leaders in stainless steel honeycomb panel manufacturing consistently acquire certifications from recognized global standards organizations, reflecting their commitment to quality and excellence. This achievement not only strengthens their reputation but also provides consumers with confidence that the products adhere to international safety and performance criteria. Moreover, the environmental impact plays a crucial role in the rising popularity of stainless steel honeycomb panels. Given the current global push towards sustainable practices, the material's recyclability makes it an attractive option for environmentally conscious projects. The panels can be fully recycled at the end of their life cycle, minimizing waste and contributing positively to green building practices. Professionals working with stainless steel honeycomb panels often highlight the blend of expertise and innovation involved in their deployment. Engineers and architects who incorporate these panels into their projects enjoy a sense of authority, able to leverage cutting-edge technology to deliver top-notch results. Their utilization is a testament to how interdisciplinary collaboration between science and creativity can produce superior construction outcomes. In summary, stainless steel honeycomb panels are setting new milestones in various industries through their impeccable design and unrivaled performance. As more industries discover their potential, these panels will surely grow in demand, continuously reshaping the landscapes of modern engineering and design. Whether it's enhancing the fuel efficiency of an aircraft or the longevity of a maritime vessel, these innovative panels are proving to be indispensable assets in a world increasingly focused on efficiency, reliability, and sustainability.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025