- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 08:40

Back to list

pannello a nido d'ape

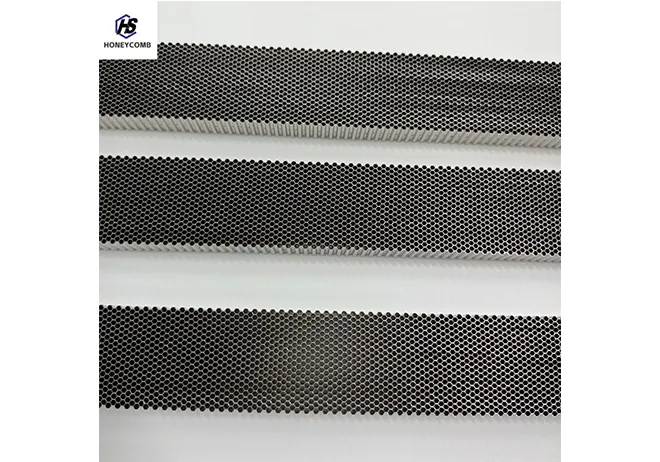

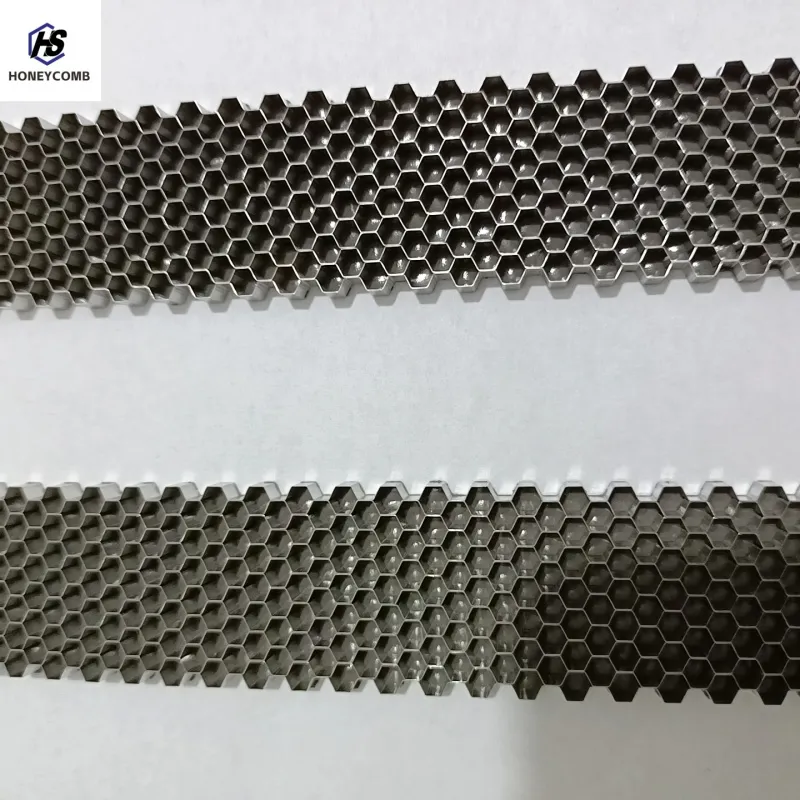

In the ever-evolving landscape of innovative materials, the pannello a nido d'ape, or honeycomb panel, has carved a niche for itself due to its exceptional versatility and performance characteristics. This structural innovation, inspired by the geometry and efficiency of natural honeycomb, has enabled advancements in numerous industries. Our intent here is to delve into the nuances of honeycomb panels, unveiling the tangible benefits and expert insights derived from extensive user experiences and professional evaluations.

Trust in honeycomb panels is solidified by their inherent durability and resistance to environmental degradation. In marine settings, for instance, these panels withstand moisture, salt, and other corrosive elements, preserving their integrity over prolonged periods. This resilience minimizes maintenance demands, assuring users of long-term value and performance consistency. Adding a layer of technical sophistication, honeycomb panels also exhibit excellent thermal and acoustic insulation properties. Aeronautical engineers, in particular, have praised these attributes, which enhance passenger comfort while maintaining cabin integrity. Similarly, in residential building applications, these panels contribute to quieter, more energy-efficient environments that align with sustainable development goals. Sustainability, a growing priority in material selection, positions honeycomb panels as a forward-thinking choice. The core materials often comprise recycled components, and the manufacturing process itself demands less energy compared to traditional materials like solid metals or dense composites. Such eco-conscious manufacturing not only meets the rising regulatory standards but also appeals to environmentally aware consumers aiming to reduce their carbon footprint. In conclusion, the honeycomb panel's integration into product design embodies a blend of innovation and practical utility, drawing from real-world applications and expert validations. As industries continue to embrace sustainable practices and the demand for lightweight, durable solutions grows, honeycomb panels are poised to remain at the forefront of material selection. Path-breaking research and continued field testing will further establish their role in the architectural, industrial, and transport sectors, ensuring that they are not just a trend but a mainstay in modern construction and design methodologies.

Trust in honeycomb panels is solidified by their inherent durability and resistance to environmental degradation. In marine settings, for instance, these panels withstand moisture, salt, and other corrosive elements, preserving their integrity over prolonged periods. This resilience minimizes maintenance demands, assuring users of long-term value and performance consistency. Adding a layer of technical sophistication, honeycomb panels also exhibit excellent thermal and acoustic insulation properties. Aeronautical engineers, in particular, have praised these attributes, which enhance passenger comfort while maintaining cabin integrity. Similarly, in residential building applications, these panels contribute to quieter, more energy-efficient environments that align with sustainable development goals. Sustainability, a growing priority in material selection, positions honeycomb panels as a forward-thinking choice. The core materials often comprise recycled components, and the manufacturing process itself demands less energy compared to traditional materials like solid metals or dense composites. Such eco-conscious manufacturing not only meets the rising regulatory standards but also appeals to environmentally aware consumers aiming to reduce their carbon footprint. In conclusion, the honeycomb panel's integration into product design embodies a blend of innovation and practical utility, drawing from real-world applications and expert validations. As industries continue to embrace sustainable practices and the demand for lightweight, durable solutions grows, honeycomb panels are poised to remain at the forefront of material selection. Path-breaking research and continued field testing will further establish their role in the architectural, industrial, and transport sectors, ensuring that they are not just a trend but a mainstay in modern construction and design methodologies.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025