- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 08:04

Back to list

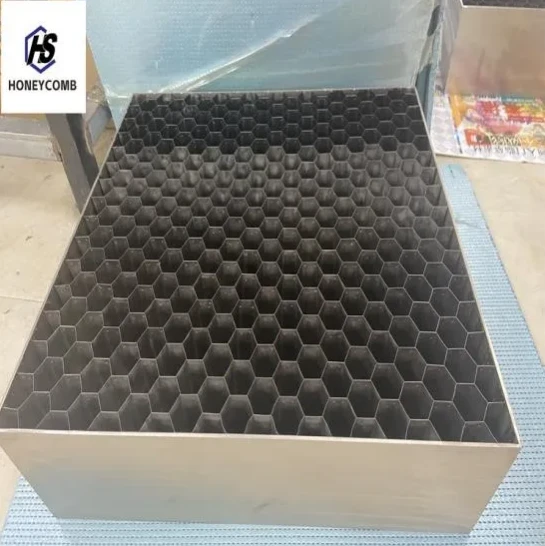

raddrizzatore di flusso a nido d'ape

The Revolutionary Impact of Honeycomb Flow Straighteners on Fluid Dynamics

The petroleum industry also benefits from this technology, where monitoring the flow of oil and gas is fraught with challenges due to the complex nature of these fluids. Honeycomb flow straighteners are utilized to maintain the consistency of flow through pipes, mitigating the risk of blockages and ensuring the safe and efficient transport of resources. The credibility and trustworthiness of these devices are reflected in their widespread application across such critical infrastructure. One might wonder, what makes these devices essential across so many sectors? The answer lies in their proven ability to meet rigorous industrial demands. Produced from high-quality materials like stainless steel or aluminum, they are durable and capable of withstanding extreme temperatures and pressures. The robustness of honeycomb flow straighteners ensures long-term performance and reliability, making them a trusted component in fluid regulatory systems. Moreover, their simple installation and minimal maintenance requirements add to their appeal, offering a cost-effective solution for enhancing fluid flow efficiency. As industries increasingly lean towards systems that reduce environmental impact, the energy savings achieved through improved fluid dynamics further cement the value of incorporating honeycomb flow straighteners in various applications. As an expert, it is essential to acknowledge the innovative strides this product represents within the engineering community. Its authoritative use and reliable performance are transforming fluid management in substantial ways, providing engineers with the tool needed to overcome complex flow challenges. When accuracy and consistency are paramount, honeycomb flow straighteners offer a cutting-edge solution that is both trusted and proven. In conclusion, honeycomb flow straighteners are more than just a component; they are a testament to engineering brilliance applied in real-world scenarios. As industries evolve, the demand for efficient and reliable fluid management tools will intensify, positioning honeycomb flow straighteners at the forefront of technological advancement in fluid dynamics. The investment in these devices signals a commitment to precision, efficiency, and sustainability, ensuring they remain integral to future developments in a wide array of industries.

The petroleum industry also benefits from this technology, where monitoring the flow of oil and gas is fraught with challenges due to the complex nature of these fluids. Honeycomb flow straighteners are utilized to maintain the consistency of flow through pipes, mitigating the risk of blockages and ensuring the safe and efficient transport of resources. The credibility and trustworthiness of these devices are reflected in their widespread application across such critical infrastructure. One might wonder, what makes these devices essential across so many sectors? The answer lies in their proven ability to meet rigorous industrial demands. Produced from high-quality materials like stainless steel or aluminum, they are durable and capable of withstanding extreme temperatures and pressures. The robustness of honeycomb flow straighteners ensures long-term performance and reliability, making them a trusted component in fluid regulatory systems. Moreover, their simple installation and minimal maintenance requirements add to their appeal, offering a cost-effective solution for enhancing fluid flow efficiency. As industries increasingly lean towards systems that reduce environmental impact, the energy savings achieved through improved fluid dynamics further cement the value of incorporating honeycomb flow straighteners in various applications. As an expert, it is essential to acknowledge the innovative strides this product represents within the engineering community. Its authoritative use and reliable performance are transforming fluid management in substantial ways, providing engineers with the tool needed to overcome complex flow challenges. When accuracy and consistency are paramount, honeycomb flow straighteners offer a cutting-edge solution that is both trusted and proven. In conclusion, honeycomb flow straighteners are more than just a component; they are a testament to engineering brilliance applied in real-world scenarios. As industries evolve, the demand for efficient and reliable fluid management tools will intensify, positioning honeycomb flow straighteners at the forefront of technological advancement in fluid dynamics. The investment in these devices signals a commitment to precision, efficiency, and sustainability, ensuring they remain integral to future developments in a wide array of industries.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025