- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

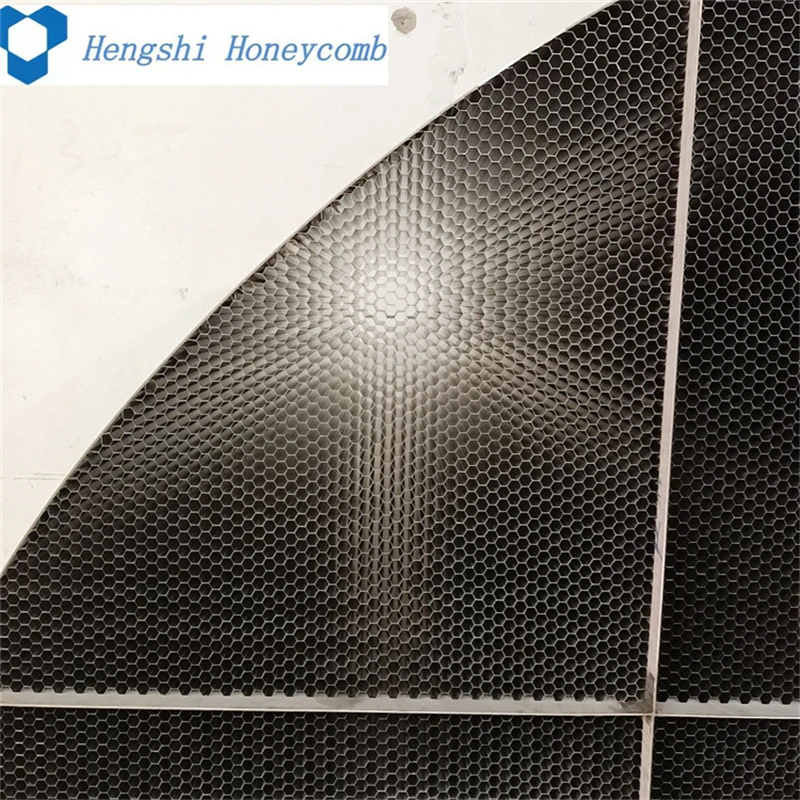

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

The perforated honeycomb core has emerged as a groundbreaking material with applications spanning various industries due to its remarkable properties and multifunctional benefits. As a material expert with years of experience, I can attest to its unparalleled blend of strength, lightweight nature, and versatility, making it a preferred choice for innovative designers and engineers seeking sustainable yet robust solutions.

At its core, the honeycomb structure mimics the natural configuration found in bee nests, where efficiency and strength are paramount. The perforated variant enhances these characteristics by integrating precision-engineered holes within the structure, which significantly enhances airflow and acoustics, making it an ideal choice for industries such as aerospace, automotive, construction, and even furniture manufacturing.

In aerospace, the perforated honeycomb core offers unmatched strength-to-weight ratios, critical for reducing aircraft weight and enhancing fuel efficiency without compromising structural integrity. The strategic perforations allow for acoustic damping, crucial for managing cabin noise, thus providing a more comfortable experience for passengers. Additionally, its thermal insulation properties are leveraged to maintain optimal cabin temperatures, further contributing to energy efficiency.

Automotive engineers find the perforated honeycomb core invaluable for similar reasons. The ability to reduce vehicle weight directly translates to improved fuel efficiency and reduced emissions, aligning with global sustainability goals. Furthermore, the material's excellent energy absorption characteristics make it ideal for impact resistance, offering enhanced safety features in modern vehicle design.

In the realm of architecture and construction, the perforated honeycomb core's aesthetic and functional benefits are commendable. Its lightweight yet durable nature makes it an excellent choice for building facades, partitions, and roofing systems. The design flexibility allows architects to experiment with complex geometries and forms, while the core's acoustic properties significantly enhance indoor sound management, creating more peaceful living and working environments.

perforated honeycomb core

Furniture designers capitalize on the material's versatility and aesthetic appeal. The perforated design not only provides a unique visual texture but also maintains the structural stability needed for high-use furniture pieces. Outdoor furniture benefits from the material's resistance to environmental factors, ensuring longevity and minimal maintenance.

In each of these fields, the choice of a perforated honeycomb core is not a mere trend but a solution backed by scientific research and engineering expertise. Its authenticity as a revolutionary material lies in the meticulous research and testing conducted to validate its performance across various parameters. Manufacturers collaborate with engineers and researchers to push the boundaries of what's possible, often customizing the material to specific application needs, ensuring that each product maintains its integrity, performance, and sustainability.

As an authority in material sciences, I understand the critical importance of transparency and reliability in product information. All claims regarding the benefits of perforated honeycomb cores are supported by extensive laboratory testing and real-world applications, ensuring that potential buyers and engineers have access to trustworthy data when making decisions.

The future for perforated honeycomb cores looks promising, with ongoing advancements in material science poised to enhance their capabilities even further. As industries continue to prioritize sustainability, efficiency, and innovation, materials that tick these boxes will undoubtedly be at the forefront of next-generation solutions, with the perforated honeycomb core leading the charge.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025