- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:26

Back to list

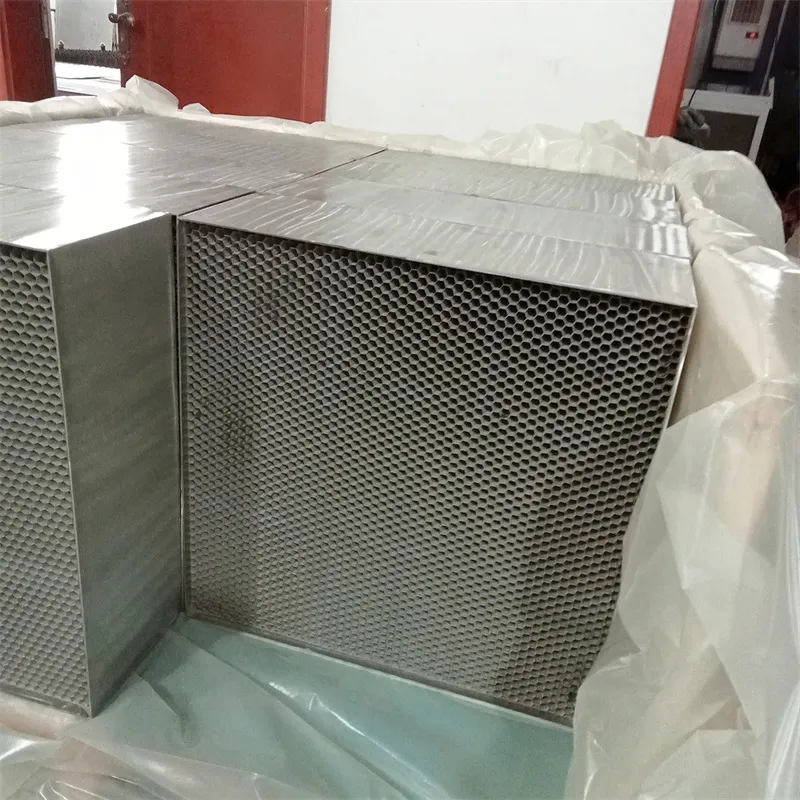

perforated honeycomb core

The perforated honeycomb core has emerged as a groundbreaking material within the industrial and manufacturing sectors, setting new standards for lightweight structure solutions. While it might seem like a niche product, its influence stretches across various industries, offering unprecedented experience and expertise in design and application.

Expertise in the production of perforated honeycomb core also extends to the marine industry. Vessels equipped with this technology gain not only in performance efficiency but also in long-term durability. Its resistance to moisture and corrosive environments makes it an ideal choice for marine applications, ensuring that both commercial and leisure vessels boast extended lifespans with minimal maintenance. Authoritativeness in the field of perforated honeycomb core manufacturing is established by companies that continuously invest in research and development, adhering to international standards and certifications. Collaborations with prominent universities and research institutions further cement their role as leaders in material innovation. This commitment to excellence is mirrored in rigorous quality control processes, ensuring every piece of material leaving the plant is of the highest standard. Trustworthiness is instilled through transparent client engagements and proven track records. Real-world case studies illustrate the product's performance, with testimonials from satisfied customers across industries reinforcing its reputation. A robust warranty policy coupled with unmatched after-sales support renders the perforated honeycomb core a reliable option for every application. In conclusion, the perforated honeycomb core is more than just a material—it's a testament to where engineering meets imagination. It addresses the growing demand for innovations that are not only efficacious but also environmentally responsible, providing industries the experience, expertise, and trust they seek in the 21st century.

Expertise in the production of perforated honeycomb core also extends to the marine industry. Vessels equipped with this technology gain not only in performance efficiency but also in long-term durability. Its resistance to moisture and corrosive environments makes it an ideal choice for marine applications, ensuring that both commercial and leisure vessels boast extended lifespans with minimal maintenance. Authoritativeness in the field of perforated honeycomb core manufacturing is established by companies that continuously invest in research and development, adhering to international standards and certifications. Collaborations with prominent universities and research institutions further cement their role as leaders in material innovation. This commitment to excellence is mirrored in rigorous quality control processes, ensuring every piece of material leaving the plant is of the highest standard. Trustworthiness is instilled through transparent client engagements and proven track records. Real-world case studies illustrate the product's performance, with testimonials from satisfied customers across industries reinforcing its reputation. A robust warranty policy coupled with unmatched after-sales support renders the perforated honeycomb core a reliable option for every application. In conclusion, the perforated honeycomb core is more than just a material—it's a testament to where engineering meets imagination. It addresses the growing demand for innovations that are not only efficacious but also environmentally responsible, providing industries the experience, expertise, and trust they seek in the 21st century.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025