- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:50

Back to list

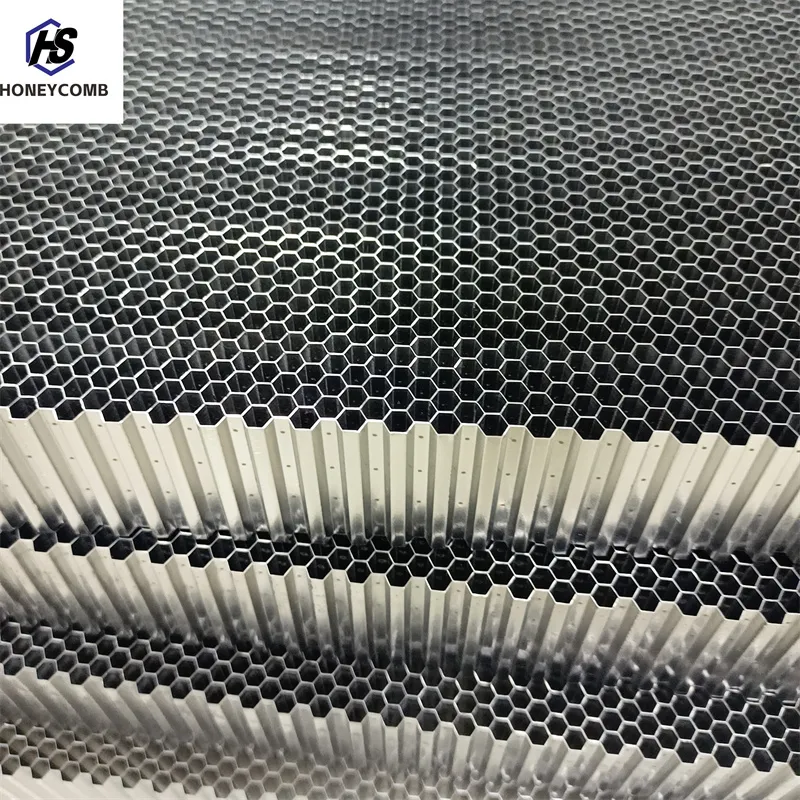

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

Perforated honeycomb cores are revolutionizing various industries with their unique combination of lightweight properties, strength, and versatility. These advanced materials are particularly making waves in the aerospace, transportation, and construction sectors. As global industries push towards sustainability and efficiency, the demand for perforated honeycomb cores is on the rise, offering a compelling balance of performance and environmental benefits.

The production of perforated honeycomb cores aligns well with eco-friendly practices. Many manufacturers are adopting sustainable sourcing and production processes, using recyclable materials, and reducing energy consumption during fabrication. These environmentally conscious practices resonate with eco-minded companies aiming to minimize their carbon footprints. As the global emphasis on sustainability grows, perforated honeycomb cores stand out not only for their technical merits but also for their eco-friendly appeal. In the realm of customization and adaptability, perforated honeycomb cores excel. They can be tailored to specific needs—varying in dimensions, cell size, thickness, and material composition—to meet precise engineering requirements. This adaptability makes them an indispensable component in industries with specialized demands, such as customized transport solutions and innovative building designs. Engineers and architects are continually exploring new applications, leveraging the material’s flexibility to push the boundaries of innovation. Trust in perforated honeycomb cores is bolstered by rigorous testing and compliance with international standards. Leading manufacturers conduct comprehensive evaluations to ensure the cores meet or exceed industry specifications for safety, durability, and performance. When integrated into critical applications, these assurance measures serve to cement their reliability and trustworthiness, making them a go-to choice for critical projects in defense, aerospace, and automotive industries. To sum up, perforated honeycomb cores are not just materials; they represent a convergence of engineering excellence, sustainability, and modern innovation. Their ability to offer lightweight yet robust solutions, combined with eco-friendly production and customization capabilities, places them at the forefront of materials science. As industries continue to evolve, the versatility and benefits of perforated honeycomb cores are likely to inspire further advancements, meeting the demands of contemporary and future engineering and environmental challenges head-on. Equipped with cutting-edge properties and a proven track record, these cores underscore a commitment to progress, shaping a sustainable future across multiple sectors.

The production of perforated honeycomb cores aligns well with eco-friendly practices. Many manufacturers are adopting sustainable sourcing and production processes, using recyclable materials, and reducing energy consumption during fabrication. These environmentally conscious practices resonate with eco-minded companies aiming to minimize their carbon footprints. As the global emphasis on sustainability grows, perforated honeycomb cores stand out not only for their technical merits but also for their eco-friendly appeal. In the realm of customization and adaptability, perforated honeycomb cores excel. They can be tailored to specific needs—varying in dimensions, cell size, thickness, and material composition—to meet precise engineering requirements. This adaptability makes them an indispensable component in industries with specialized demands, such as customized transport solutions and innovative building designs. Engineers and architects are continually exploring new applications, leveraging the material’s flexibility to push the boundaries of innovation. Trust in perforated honeycomb cores is bolstered by rigorous testing and compliance with international standards. Leading manufacturers conduct comprehensive evaluations to ensure the cores meet or exceed industry specifications for safety, durability, and performance. When integrated into critical applications, these assurance measures serve to cement their reliability and trustworthiness, making them a go-to choice for critical projects in defense, aerospace, and automotive industries. To sum up, perforated honeycomb cores are not just materials; they represent a convergence of engineering excellence, sustainability, and modern innovation. Their ability to offer lightweight yet robust solutions, combined with eco-friendly production and customization capabilities, places them at the forefront of materials science. As industries continue to evolve, the versatility and benefits of perforated honeycomb cores are likely to inspire further advancements, meeting the demands of contemporary and future engineering and environmental challenges head-on. Equipped with cutting-edge properties and a proven track record, these cores underscore a commitment to progress, shaping a sustainable future across multiple sectors.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025