- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:52

Back to list

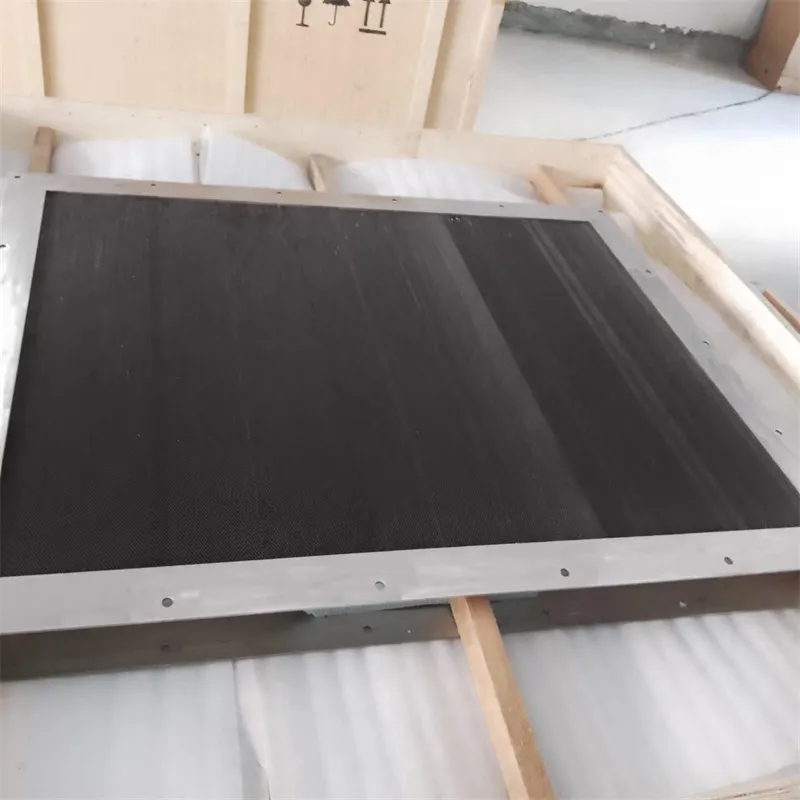

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The fascinating efficiency of honeycomb plates has propelled their popularity across diverse industries, from aerospace to architecture. These structures mimic the natural design of a bee’s honeycomb, providing incredible strength-to-weight ratios that offer the sought-after balance between durability and lightness. At the core of this innovation lies an ingenious design, highly respected by engineers and architects worldwide.

The trustworthiness of honeycomb structures is backed by extensive research and historical application outcomes. The methodology behind their design is rooted in biomimicry and fundamental physics, showcasing nature’s inherent wisdom. Research studies consistently validate their performance under rigorous testing conditions, spanning temperature fluctuations, impact resistance, and prolonged exposure to harsh environments. As a product, they epitomize the blend of scientific principles with real-world application—mirroring a legacy that has been tested over millions of years of evolution. Professionals leveraging honeycomb plates benefit from a wealth of expertise shared across global platforms. Educational forums, technical webinars, and international symposiums have developed around this technology. These platforms are indispensable resources for professionals seeking to deepen their understanding of material properties and manufacturing techniques, enabling innovative applications across all manner of projects. When specifying honeycomb products, selection of the proper material composition and configuration is paramount to achieving desired outcomes. Engaging with manufacturers who possess authoritative expertise ensures that products meet specific project demands—whether they're bearing loads, providing impact resistance, insulating, or a combination of multiple functions. Trust is earned through demonstrated quality and the capability to tailor solutions to industry-specific requirements, affirming the customer's confidence in their investment. In summary, honeycomb plates offer a myriad of advantages derived from their light weight, strength, and popularity across various high-stake industries. They exemplify a sophisticated harmony between organic inspiration and advanced engineering. Choosing honeycomb solutions not only optimizes structural performance but also aligns with sustainable living and operational efficiency goals. Through continued advancement and application, honeycomb plates promise to remain at the forefront of innovative technology, capable of transforming industries and pushing the limits of engineering creativity.

The trustworthiness of honeycomb structures is backed by extensive research and historical application outcomes. The methodology behind their design is rooted in biomimicry and fundamental physics, showcasing nature’s inherent wisdom. Research studies consistently validate their performance under rigorous testing conditions, spanning temperature fluctuations, impact resistance, and prolonged exposure to harsh environments. As a product, they epitomize the blend of scientific principles with real-world application—mirroring a legacy that has been tested over millions of years of evolution. Professionals leveraging honeycomb plates benefit from a wealth of expertise shared across global platforms. Educational forums, technical webinars, and international symposiums have developed around this technology. These platforms are indispensable resources for professionals seeking to deepen their understanding of material properties and manufacturing techniques, enabling innovative applications across all manner of projects. When specifying honeycomb products, selection of the proper material composition and configuration is paramount to achieving desired outcomes. Engaging with manufacturers who possess authoritative expertise ensures that products meet specific project demands—whether they're bearing loads, providing impact resistance, insulating, or a combination of multiple functions. Trust is earned through demonstrated quality and the capability to tailor solutions to industry-specific requirements, affirming the customer's confidence in their investment. In summary, honeycomb plates offer a myriad of advantages derived from their light weight, strength, and popularity across various high-stake industries. They exemplify a sophisticated harmony between organic inspiration and advanced engineering. Choosing honeycomb solutions not only optimizes structural performance but also aligns with sustainable living and operational efficiency goals. Through continued advancement and application, honeycomb plates promise to remain at the forefront of innovative technology, capable of transforming industries and pushing the limits of engineering creativity.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025