- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:54

Back to list

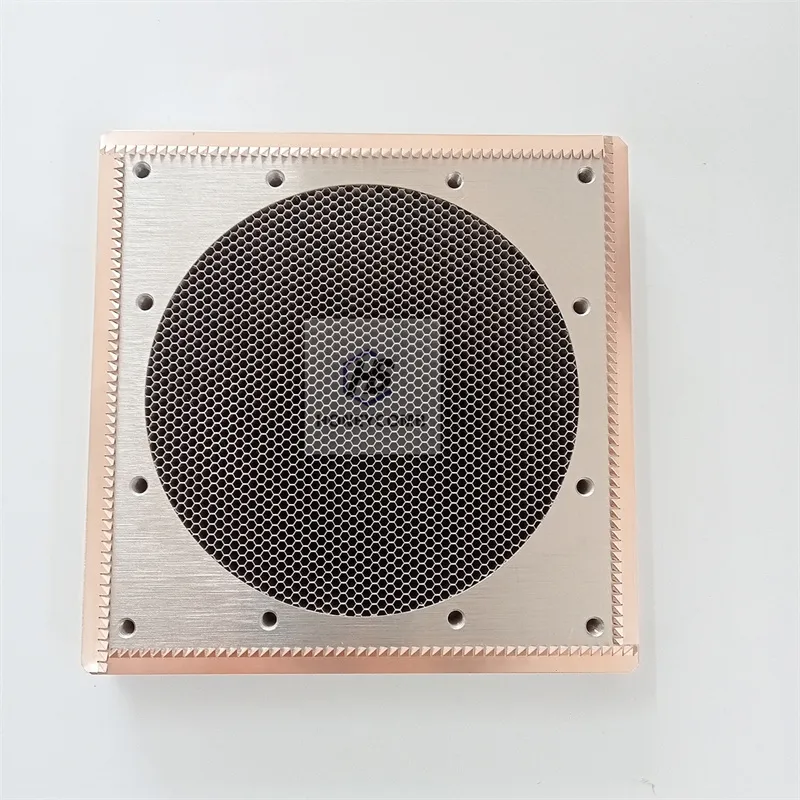

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Metal honeycombs have emerged as a fascinating innovation in materials engineering, promising a wide array of applications across industries. Constructed from metallic sheets arranged in a honeycomb pattern, these structures boast an exceptional combination of lightweight and high strength, along with resilience, thermal conductivity, and corrosion resistance. The unique properties of metal honeycombs are derived from their geometric configuration, inspired by nature's own brilliance.

From an expertise standpoint, the production of metal honeycombs requires advanced knowledge of metallurgy and engineering design. It involves precise control over material selection and fabrication techniques, ensuring that the final product meets rigorous industry standards. This expertise guarantees that metal honeycombs perform reliably in their intended applications, resonating with the authoritative demands of sectors such as space exploration and transportation infrastructure. The trustworthiness of metal honeycomb structures is underscored by their extensive testing and proven performance in demanding conditions. Industries that utilize these materials count on their consistent quality and reliability, supported by years of research and development. The integrity of these structures reassures stakeholders of their suitability in long-term applications, from high-stakes aerospace missions to everyday automotive safety. In conclusion, metal honeycombs represent a cutting-edge intersection of natural design and advanced engineering. Their advantages resonate across multiple domains, offering pioneering solutions that address contemporary challenges in efficiency, safety, and sustainability. As industries continue to explore the potential of these materials, the role of metal honeycombs in shaping the future of technology and infrastructure becomes increasingly evident.

From an expertise standpoint, the production of metal honeycombs requires advanced knowledge of metallurgy and engineering design. It involves precise control over material selection and fabrication techniques, ensuring that the final product meets rigorous industry standards. This expertise guarantees that metal honeycombs perform reliably in their intended applications, resonating with the authoritative demands of sectors such as space exploration and transportation infrastructure. The trustworthiness of metal honeycomb structures is underscored by their extensive testing and proven performance in demanding conditions. Industries that utilize these materials count on their consistent quality and reliability, supported by years of research and development. The integrity of these structures reassures stakeholders of their suitability in long-term applications, from high-stakes aerospace missions to everyday automotive safety. In conclusion, metal honeycombs represent a cutting-edge intersection of natural design and advanced engineering. Their advantages resonate across multiple domains, offering pioneering solutions that address contemporary challenges in efficiency, safety, and sustainability. As industries continue to explore the potential of these materials, the role of metal honeycombs in shaping the future of technology and infrastructure becomes increasingly evident.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025