- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 15:12

Back to list

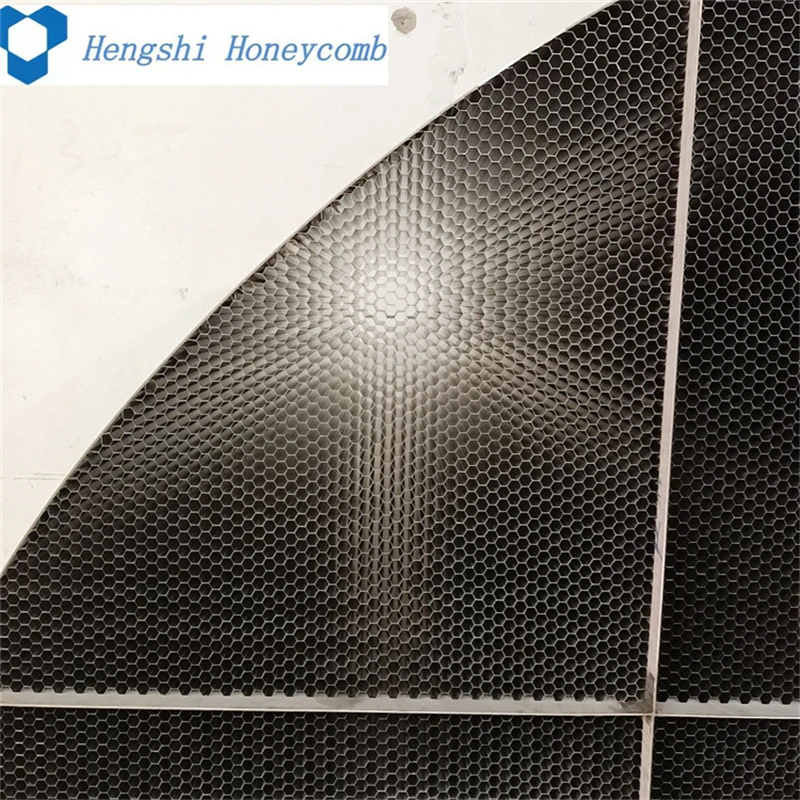

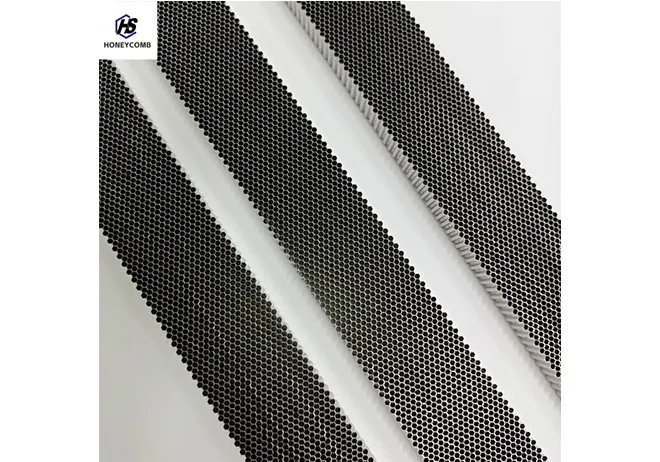

placa de panal metálico

The use of metal honeycomb panels has revolutionized various industries, offering a blend of durability, lightweight structure, and aesthetic appeal. As an innovative material, metal honeycomb panels play a critical role in architecture, furniture design, automotive manufacturing, and aerospace applications. Understanding its expansive potential is key to leveraging this product effectively.

Aerospace is another sector where metal honeycomb panels have proven indispensable. Their lightweight yet robust nature aligns perfectly with the industry's focus on improving payload and fuel efficiency. Coupled with thermal resistance and fire retardancy, these panels contribute to constructing aircraft interiors that meet stringent safety and performance standards without excess weight. Choosing metal honeycomb panels extends beyond their practical benefits; environmental considerations play a significant role. Many of these panels are made from recycled materials, and at the end of their life cycle, they can be recycled again. This quality makes them a sustainable choice, aligning with global efforts to reduce carbon footprints. For businesses looking to implement metal honeycomb panels, collaboration with experienced manufacturers is essential. Working closely with experts ensures that the panels meet specific requirements, which may vary considerably between applications. Expertise in materials science and engineering allows for modifications and enhancements that optimize function and cost-efficiency. Credibility in selecting and implementing these materials is bolstered by choosing products tested and certified by recognized bodies. Certification not only assures quality but also confirms that the materials comply with industry-specific standards for safety and performance. In summary, metal honeycomb panels stand as a testament to human ingenuity, merging form and function in various groundbreaking applications. Whether in the towering skyscrapers of bustling cities, sleek vehicles traversing highways, or aircraft soaring through the skies, these panels offer unmatched advantages. As industries continue to evolve, embracing materials like these will undoubtedly shape a more sustainable, efficient, and aesthetically pleasing future.

Aerospace is another sector where metal honeycomb panels have proven indispensable. Their lightweight yet robust nature aligns perfectly with the industry's focus on improving payload and fuel efficiency. Coupled with thermal resistance and fire retardancy, these panels contribute to constructing aircraft interiors that meet stringent safety and performance standards without excess weight. Choosing metal honeycomb panels extends beyond their practical benefits; environmental considerations play a significant role. Many of these panels are made from recycled materials, and at the end of their life cycle, they can be recycled again. This quality makes them a sustainable choice, aligning with global efforts to reduce carbon footprints. For businesses looking to implement metal honeycomb panels, collaboration with experienced manufacturers is essential. Working closely with experts ensures that the panels meet specific requirements, which may vary considerably between applications. Expertise in materials science and engineering allows for modifications and enhancements that optimize function and cost-efficiency. Credibility in selecting and implementing these materials is bolstered by choosing products tested and certified by recognized bodies. Certification not only assures quality but also confirms that the materials comply with industry-specific standards for safety and performance. In summary, metal honeycomb panels stand as a testament to human ingenuity, merging form and function in various groundbreaking applications. Whether in the towering skyscrapers of bustling cities, sleek vehicles traversing highways, or aircraft soaring through the skies, these panels offer unmatched advantages. As industries continue to evolve, embracing materials like these will undoubtedly shape a more sustainable, efficient, and aesthetically pleasing future.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025