- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 14:36

Back to list

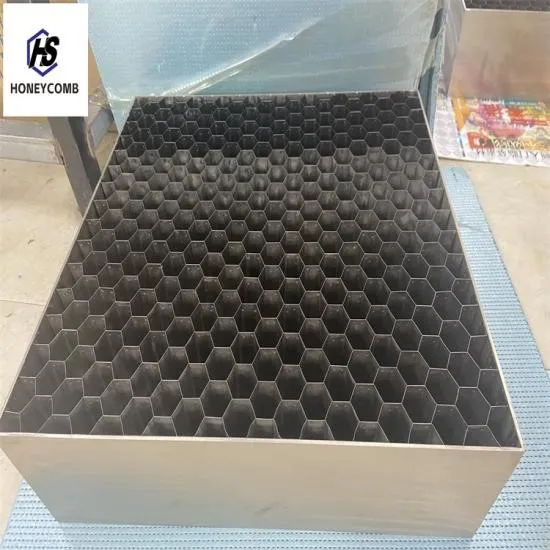

placa metálica de panal

The metallic honeycomb panel is revolutionizing various industries, becoming indispensable due to its unique blend of durability, aesthetic appeal, and performance efficiency. This expert piece delves into the transformative characteristics of metallic honeycomb panels, substantiating their growing relevancy in today's technological and architectural advancements.

Innovation in Production Advances in manufacturing technologies have strengthened the adoption of metallic honeycomb panels. Techniques like adhesive-free bonding and 3D printing integration enhance the structural cohesion and adaptability of panels to custom shapes and sizes. This innovation speeds up installation processes, reducing labor costs and associated time, further proving their economic viability alongside raw performance metrics. Expert Endorsements Structural engineers and material scientists continue to validate the immense benefits of metallic honeycomb panels through rigorous testing and real-world applications. These endorsements underpin the growing confidence in the panels' reliability and effectiveness across diverse settings. Their ongoing research and development endeavors promise future enhancements that could introduce even smarter functionality, such as integrated sensors for structural health monitoring. Trust in Proven Performance Numerous case studies highlight the panels' success across industries. Examples include their use in high-profile architectural projects where they withstand harsh environmental conditions and retain their luster over decades. In transportation, the panels have contributed to notable advancements in vehicle performance and passenger safety, earning the trust of leading manufacturers and consumers alike. In conclusion, metallic honeycomb panels exhibit qualities that address modern demands for efficiency, sustainability, and design finesse. Their continued evolution and versatility signify a material that not only adapts to but also anticipates future industry challenges, ensuring they remain at the forefront of material innovation and application. Their impeccable credentials in expert circles further solidify their status as a pillar of modern material science.

Innovation in Production Advances in manufacturing technologies have strengthened the adoption of metallic honeycomb panels. Techniques like adhesive-free bonding and 3D printing integration enhance the structural cohesion and adaptability of panels to custom shapes and sizes. This innovation speeds up installation processes, reducing labor costs and associated time, further proving their economic viability alongside raw performance metrics. Expert Endorsements Structural engineers and material scientists continue to validate the immense benefits of metallic honeycomb panels through rigorous testing and real-world applications. These endorsements underpin the growing confidence in the panels' reliability and effectiveness across diverse settings. Their ongoing research and development endeavors promise future enhancements that could introduce even smarter functionality, such as integrated sensors for structural health monitoring. Trust in Proven Performance Numerous case studies highlight the panels' success across industries. Examples include their use in high-profile architectural projects where they withstand harsh environmental conditions and retain their luster over decades. In transportation, the panels have contributed to notable advancements in vehicle performance and passenger safety, earning the trust of leading manufacturers and consumers alike. In conclusion, metallic honeycomb panels exhibit qualities that address modern demands for efficiency, sustainability, and design finesse. Their continued evolution and versatility signify a material that not only adapts to but also anticipates future industry challenges, ensuring they remain at the forefront of material innovation and application. Their impeccable credentials in expert circles further solidify their status as a pillar of modern material science.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025