- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 05:01

Back to list

raddrizzatore dell'aria di aspirazione

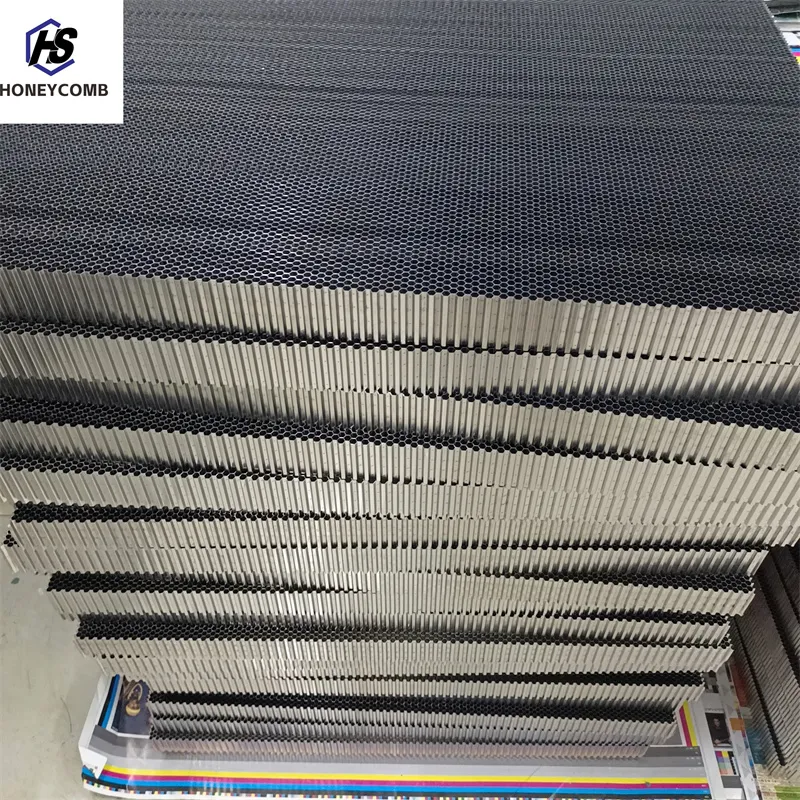

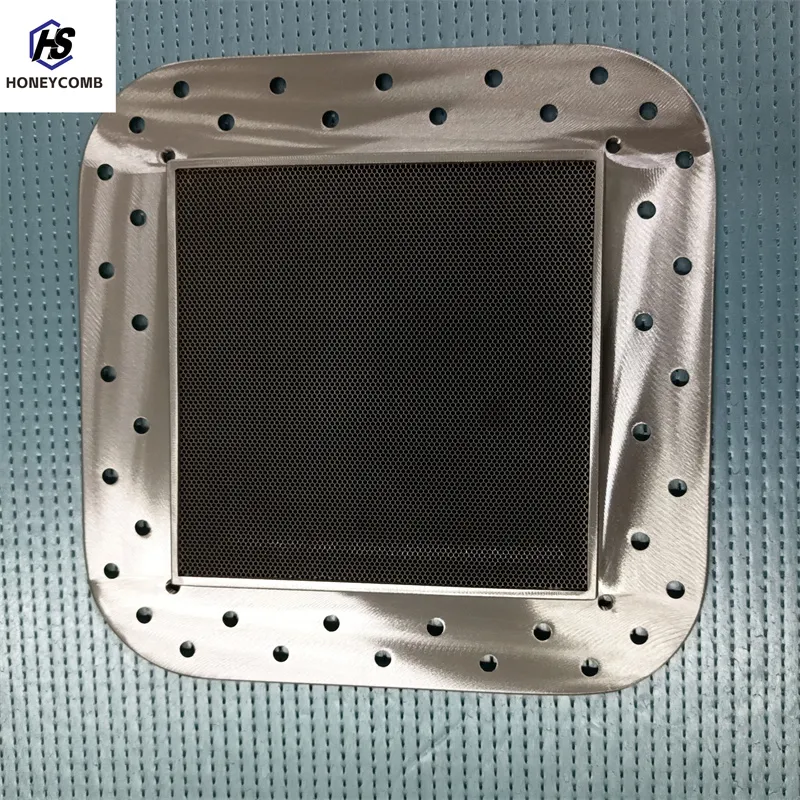

The intake air rectifier, or raddrizzatore dell'aria di aspirazione, is a critical component in automotive and industrial sectors, aimed at enhancing engine efficiency and performance. Its design and application not only improve airflow dynamics but also contribute significantly to fuel efficiency and engine longevity.

Authoritative figures in the automotive industry often discuss the importance of such components at engineering conferences and symposia. Research has consistently shown that enhancements in airflow dynamics can lead to up to a 15% increase in engine efficiency, which can translate to significant economic savings over a vehicle's lifetime. This efficiency also extends to industrial engines, where minor improvements in air intake systems can lead to substantial productivity gains. The trustworthiness of these devices is validated through rigorous testing and real-world applications. Manufacturers subject air intake rectifiers to extensive durability tests, vibration analysis, and thermal cycling to ensure reliability under varied conditions. Certification by regulatory bodies, combined with performance endorsements by professional automotive engineers, further establishes their credibility. Prospective buyers and industry professionals should focus on units with proven track records and those that come with credible certifications from recognized quality assurance bodies. Reviews and case studies from reputable sources can provide insights into the real-world performance and benefits of implementing these systems. In conclusion, the role of the intake air rectifier transcends its basic function within an engine. It embodies a fusion of scientific principles and practical applications, making it an indispensable component for modern vehicles and industrial engines. As technology continues to advance, the ongoing evolution of these systems promises even greater strides in efficiency and environmental stewardship, underscoring the indispensable role they play in the future landscape of engine technology.

Authoritative figures in the automotive industry often discuss the importance of such components at engineering conferences and symposia. Research has consistently shown that enhancements in airflow dynamics can lead to up to a 15% increase in engine efficiency, which can translate to significant economic savings over a vehicle's lifetime. This efficiency also extends to industrial engines, where minor improvements in air intake systems can lead to substantial productivity gains. The trustworthiness of these devices is validated through rigorous testing and real-world applications. Manufacturers subject air intake rectifiers to extensive durability tests, vibration analysis, and thermal cycling to ensure reliability under varied conditions. Certification by regulatory bodies, combined with performance endorsements by professional automotive engineers, further establishes their credibility. Prospective buyers and industry professionals should focus on units with proven track records and those that come with credible certifications from recognized quality assurance bodies. Reviews and case studies from reputable sources can provide insights into the real-world performance and benefits of implementing these systems. In conclusion, the role of the intake air rectifier transcends its basic function within an engine. It embodies a fusion of scientific principles and practical applications, making it an indispensable component for modern vehicles and industrial engines. As technology continues to advance, the ongoing evolution of these systems promises even greater strides in efficiency and environmental stewardship, underscoring the indispensable role they play in the future landscape of engine technology.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025