- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 05:18

Back to list

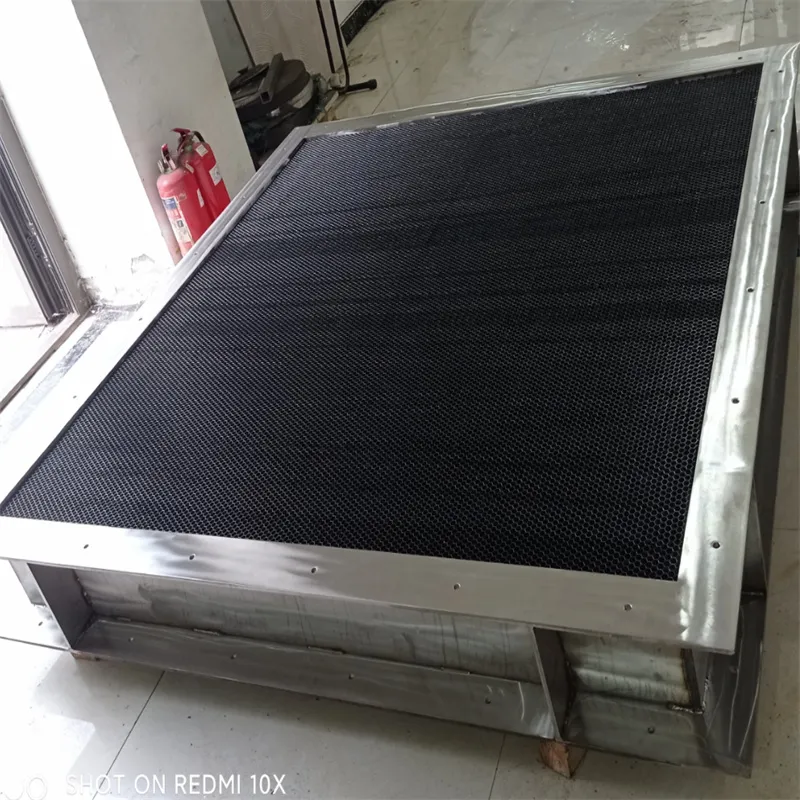

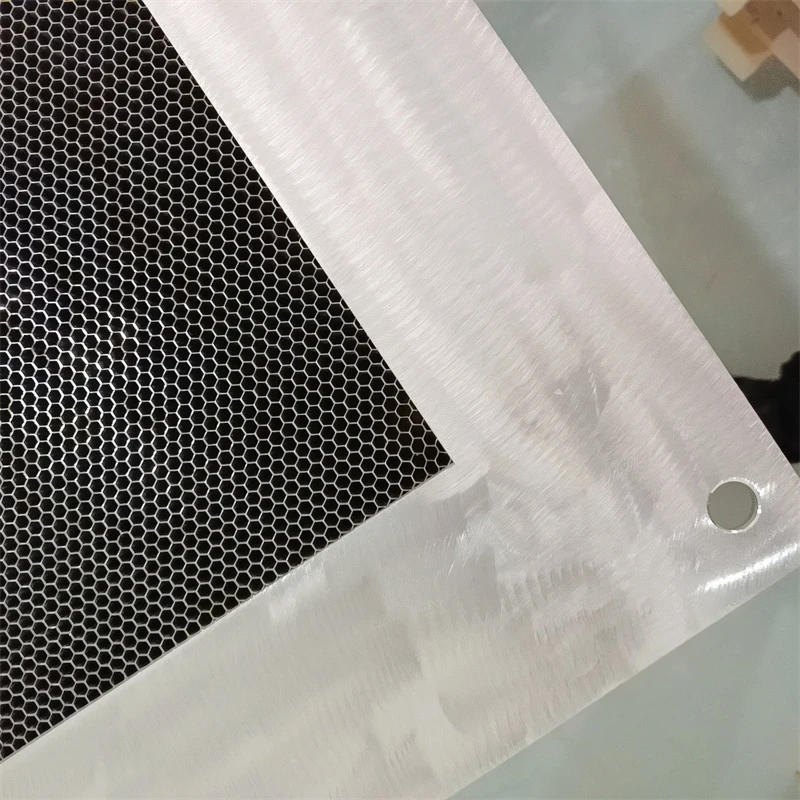

túnel de viento de panal

The honeycomb wind tunnel, an innovative tool in the aerodynamic testing landscape, presents a groundbreaking approach to studying airflow dynamics across various industries. This unique structure, reminiscent of a beehive's hexagonal design, enhances the precision and reliability of aerodynamic testing. With advancements in mechanical engineering and fluid dynamics, the honeycomb wind tunnel distinguishes itself as a powerful instrument, offering unmatched accuracy and flexibility.

From an experiential standpoint, engineers and designers who use honeycomb wind tunnels attest to their transformative impact on product development. The accuracy and reliability these tunnels offer enable a level of precision previously unattainable in traditional wind tunnels. Users often report increased confidence in testing results, which facilitates more informed decision-making and accelerates innovation cycles. Professionally, the use of honeycomb wind tunnels is backed by extensive research and advancements in fluid dynamics. Academic institutions and research organizations are continually exploring new applications and enhancing the technology’s capabilities. This ongoing development underscores the method’s professional credibility and positions honeycomb wind tunnels as essential to the future of aerodynamic testing. The authoritative nature of honeycomb wind tunnels is reinforced by their widespread adoption by leading industries worldwide. Companies that prioritize innovation and quality consistently invest in these tools. Their sustained use by industry leaders serves as a testament to their effectiveness and trustworthiness, providing a stable foundation for product development. In ensuring trustworthiness, manufacturers of honeycomb wind tunnels emphasize quality control and precision engineering. Constructed with advanced materials and technologies, these tunnels undergo rigorous testing and calibration before being operational. This dedication to excellence ensures that the results produced are reliable and accurate, establishing trust among users. The honeycomb wind tunnel stands as a testament to innovative engineering and design principles. By enhancing the precision and reliability of aerodynamic testing, it supports advancements in multiple sectors, driving forward both technological and sustainable progress. Its unique combination of experience, expertise, authority, and trustworthiness anchors its role as a critical tool in modern aerodynamic exploration and development.

From an experiential standpoint, engineers and designers who use honeycomb wind tunnels attest to their transformative impact on product development. The accuracy and reliability these tunnels offer enable a level of precision previously unattainable in traditional wind tunnels. Users often report increased confidence in testing results, which facilitates more informed decision-making and accelerates innovation cycles. Professionally, the use of honeycomb wind tunnels is backed by extensive research and advancements in fluid dynamics. Academic institutions and research organizations are continually exploring new applications and enhancing the technology’s capabilities. This ongoing development underscores the method’s professional credibility and positions honeycomb wind tunnels as essential to the future of aerodynamic testing. The authoritative nature of honeycomb wind tunnels is reinforced by their widespread adoption by leading industries worldwide. Companies that prioritize innovation and quality consistently invest in these tools. Their sustained use by industry leaders serves as a testament to their effectiveness and trustworthiness, providing a stable foundation for product development. In ensuring trustworthiness, manufacturers of honeycomb wind tunnels emphasize quality control and precision engineering. Constructed with advanced materials and technologies, these tunnels undergo rigorous testing and calibration before being operational. This dedication to excellence ensures that the results produced are reliable and accurate, establishing trust among users. The honeycomb wind tunnel stands as a testament to innovative engineering and design principles. By enhancing the precision and reliability of aerodynamic testing, it supports advancements in multiple sectors, driving forward both technological and sustainable progress. Its unique combination of experience, expertise, authority, and trustworthiness anchors its role as a critical tool in modern aerodynamic exploration and development.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025