- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 05:36

Back to list

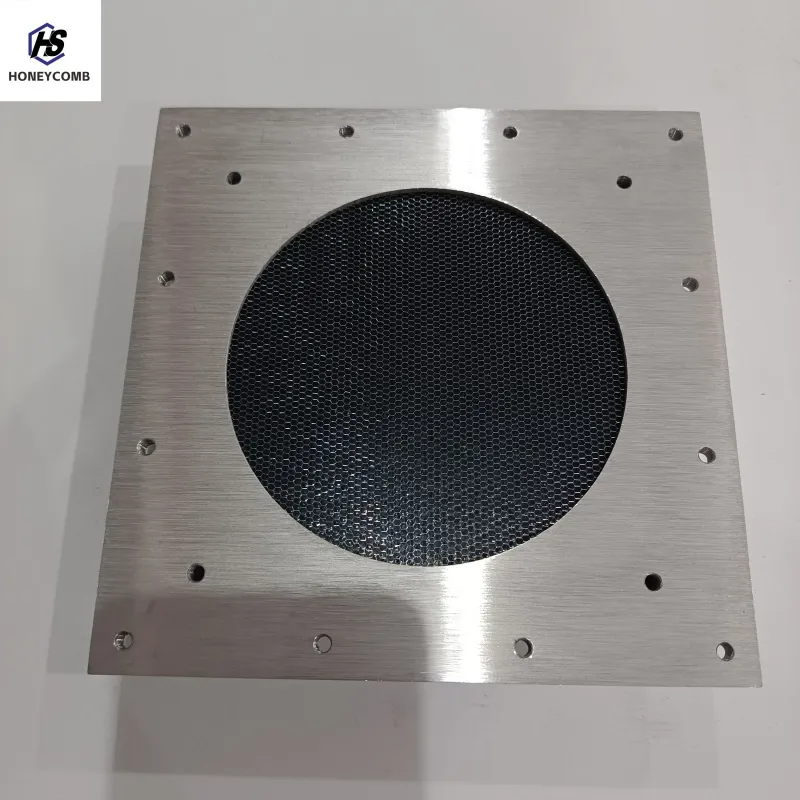

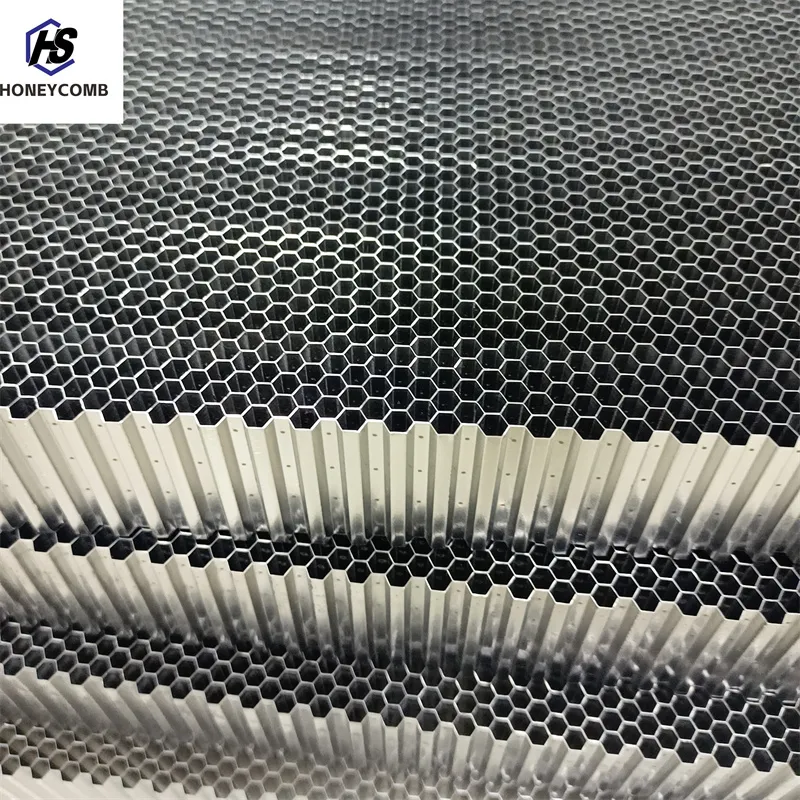

panal en el túnel de viento

In the realm of aerodynamic testing and product development, utilizing a panel in a wind tunnel has become an essential practice. These panels are engineered to optimize the understanding of aerodynamic properties, providing invaluable insights into the behavior of objects in various airflow conditions. Inherently built on principles of physics and engineering, panels used in wind tunnels embody the pinnacle of expertise and precision in aerodynamic testing.

Authority in the use of wind tunnel panels is established through rigorous testing and validation processes. Companies and research institutions rely on experienced professionals who possess a deep understanding of aerodynamic behavior and data interpretation. This trustworthiness is further reinforced by adherence to industry standards and regular calibration of wind tunnel facilities to ensure ongoing accuracy and reliability of test results. Moreover, the innovation in panel technologies continues to advance. With developments in sensor integration, panels now often come equipped with embedded pressure sensors or strain gauges. These technologies provide real-time data feedback, enhancing the ability of engineers to understand complex aerodynamic influences at a granular level. This level of detail not only improves product performance but also accelerates the development process by highlighting design flaws or areas for enhancement early in the testing phase. In summary, panels in wind tunnels are indispensable tools for modern aerodynamic evaluation and product development. They embody the convergence of experience, expertise, authority, and trustworthiness, serving as the backbone of experimental accuracy in the field of aerodynamics. As technology progresses, the continuous refinement of these panels and their associated methodologies ensures they remain at the forefront of innovation, driving advancements in industries that demand the highest levels of aerodynamic efficiency and precision.

Authority in the use of wind tunnel panels is established through rigorous testing and validation processes. Companies and research institutions rely on experienced professionals who possess a deep understanding of aerodynamic behavior and data interpretation. This trustworthiness is further reinforced by adherence to industry standards and regular calibration of wind tunnel facilities to ensure ongoing accuracy and reliability of test results. Moreover, the innovation in panel technologies continues to advance. With developments in sensor integration, panels now often come equipped with embedded pressure sensors or strain gauges. These technologies provide real-time data feedback, enhancing the ability of engineers to understand complex aerodynamic influences at a granular level. This level of detail not only improves product performance but also accelerates the development process by highlighting design flaws or areas for enhancement early in the testing phase. In summary, panels in wind tunnels are indispensable tools for modern aerodynamic evaluation and product development. They embody the convergence of experience, expertise, authority, and trustworthiness, serving as the backbone of experimental accuracy in the field of aerodynamics. As technology progresses, the continuous refinement of these panels and their associated methodologies ensures they remain at the forefront of innovation, driving advancements in industries that demand the highest levels of aerodynamic efficiency and precision.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025