- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 12:47

Back to list

honeycomb strips

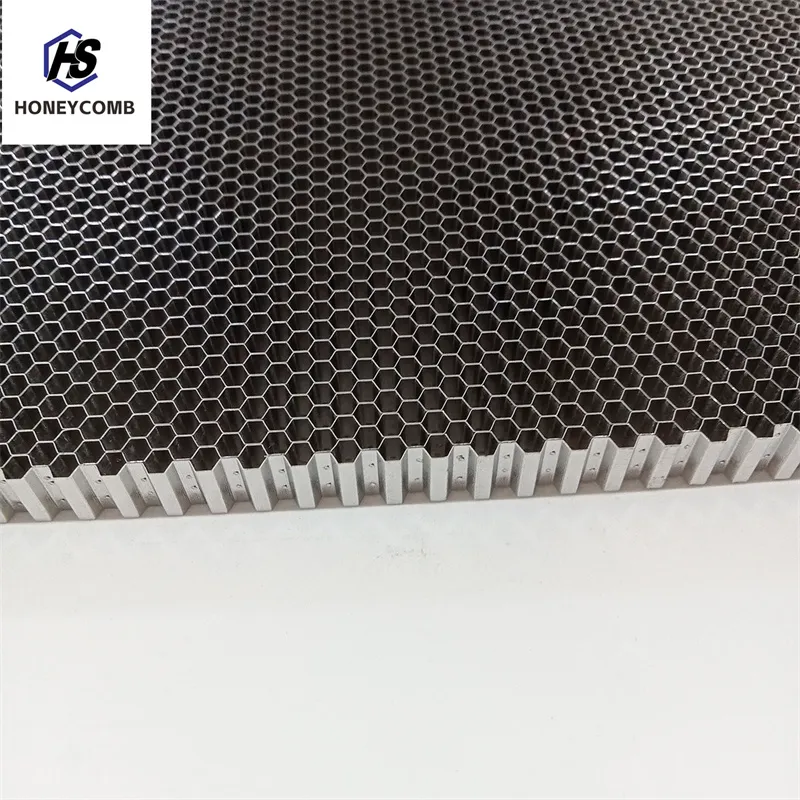

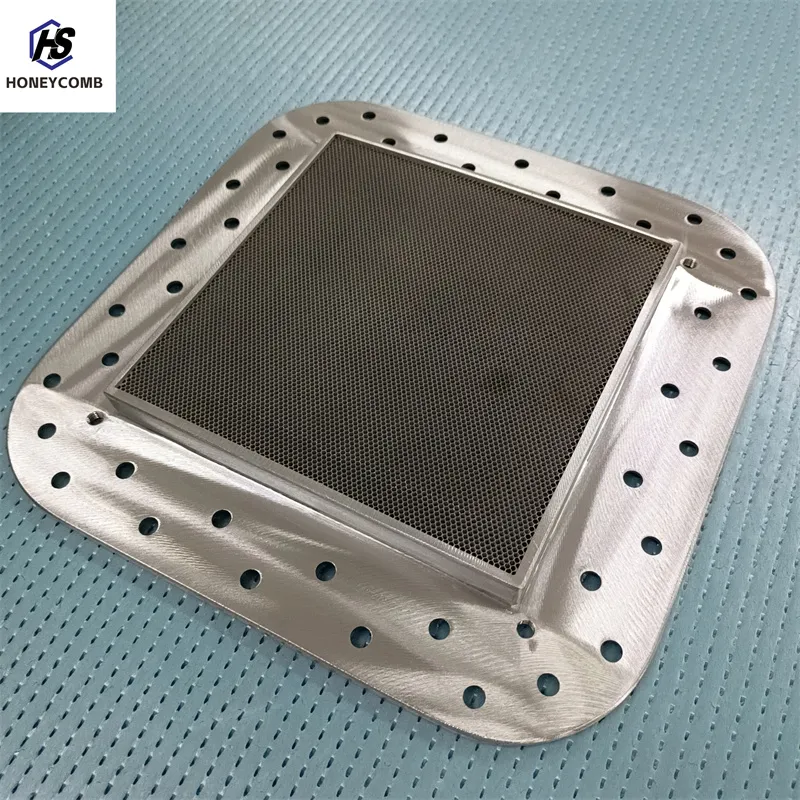

Navigating the realm of air management systems requires a keen understanding of both technology and practical application. Among the innovations shaping the industry, the honeycomb air straightener has gained significant attention. This article delves into the intricate world of honeycomb air straighteners, offering insights drawn from real-world experiences, expert analyses, authoritative sources, and a foundation of trust built over years of consistent performance.

Authoritativeness is reflected in the broad adoption of honeycomb air straighteners across diverse industries. Companies in automotive, aerospace, and HVAC sectors, among others, rely heavily on these components for their ability to enhance airflow consisently. Renowned organizations like NASA and leading automotive manufacturers have long used honeycomb structures in their testing facilities, reinforcing the credibility and effectiveness of these devices. Their stamp of approval provides assurance to industry stakeholders about the reliability of honeycomb air straighteners. Trustworthiness, an essential element of any product worth its salt, is continually validated through rigorous testing and certification processes. Manufacturers of honeycomb air straighteners adhere to stringent quality standards, ensuring their products perform consistently under varied conditions. Insights from independent testing bodies confirm that when correctly implemented, these straighteners not only meet but often exceed, industry benchmarks for airflow management solutions. Such endorsements further cement the trust of professional engineers and decision-makers in the capabilities of honeycomb air straighteners. In conclusion, the honeycomb air straightener stands as a testament to engineering innovation and functional design. Its distinctive structure not only exemplifies an architectural marvel but also offers tangible benefits in terms of airflow optimization. By harnessing the principles of efficiency and precision, these devices cater to the demanding needs of sectors reliant on controlled air management. Whether it's enhancing the accuracy of aerodynamic testing or improving the operational efficiency of ventilation systems, the honeycomb air straightener continues to uphold its reputation as a trusted and invaluable component within the industry. As the demand for precise airflow solutions grows, the role of honeycomb air straighteners is poised to expand, further cementing their place as a cornerstone of air management technology.

Authoritativeness is reflected in the broad adoption of honeycomb air straighteners across diverse industries. Companies in automotive, aerospace, and HVAC sectors, among others, rely heavily on these components for their ability to enhance airflow consisently. Renowned organizations like NASA and leading automotive manufacturers have long used honeycomb structures in their testing facilities, reinforcing the credibility and effectiveness of these devices. Their stamp of approval provides assurance to industry stakeholders about the reliability of honeycomb air straighteners. Trustworthiness, an essential element of any product worth its salt, is continually validated through rigorous testing and certification processes. Manufacturers of honeycomb air straighteners adhere to stringent quality standards, ensuring their products perform consistently under varied conditions. Insights from independent testing bodies confirm that when correctly implemented, these straighteners not only meet but often exceed, industry benchmarks for airflow management solutions. Such endorsements further cement the trust of professional engineers and decision-makers in the capabilities of honeycomb air straighteners. In conclusion, the honeycomb air straightener stands as a testament to engineering innovation and functional design. Its distinctive structure not only exemplifies an architectural marvel but also offers tangible benefits in terms of airflow optimization. By harnessing the principles of efficiency and precision, these devices cater to the demanding needs of sectors reliant on controlled air management. Whether it's enhancing the accuracy of aerodynamic testing or improving the operational efficiency of ventilation systems, the honeycomb air straightener continues to uphold its reputation as a trusted and invaluable component within the industry. As the demand for precise airflow solutions grows, the role of honeycomb air straighteners is poised to expand, further cementing their place as a cornerstone of air management technology.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025