- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 21, 2025 04:36

Back to list

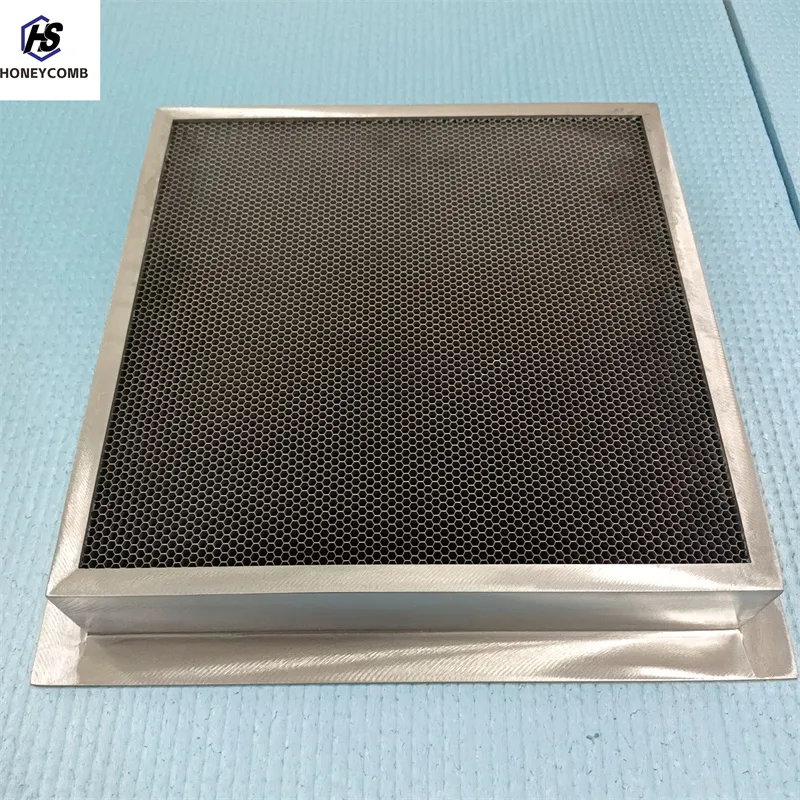

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

The stainless steel honeycomb structure is revolutionizing several industries, from aerospace to architecture, due to its unique combination of strength, versatility, and sustainability. Companies and consumers alike need to understand the intrinsic benefits and applications of stainless steel honeycomb panels to make informed decisions that leverage its potential effectively.

Moreover, the environmental implications of choosing stainless steel honeycomb panels cannot be overlooked. In today's eco-conscious world, the recyclability of stainless steel easily aligns with global sustainability goals. The production processes for these panels are typically more environmentally friendly compared to alternative materials, and the lifespan of rightfully constructed stainless steel honeycomb structures significantly curtails the need for replacement, reducing waste and resource consumption. As experts in material science continue to push the boundaries of what's possible with stainless steel honeycomb structures, industries must keep pace with these advancements to fully exploit the advantages they offer. It's crucial for businesses to align with manufacturers who not only have the technical expertise but also adhere to strict quality control standards to ensure the integrity of the stainless steel used. Trustworthiness in sourcing and manufacturing processes directly correlates with the performance and longevity of the end product. With a proven track record and ongoing advancements, stainless steel honeycomb structures are poised to become a staple in modern design and manufacturing. Industries that embrace this innovative material will benefit not only from its practical applications and aesthetic qualities but also from its alignment with sustainable practices. Therefore, understanding and integrating stainless steel honeycomb panels into relevant areas of application is a strategic move for any forward-thinking organization aiming to enhance performance while supporting environmental stewardship.

Moreover, the environmental implications of choosing stainless steel honeycomb panels cannot be overlooked. In today's eco-conscious world, the recyclability of stainless steel easily aligns with global sustainability goals. The production processes for these panels are typically more environmentally friendly compared to alternative materials, and the lifespan of rightfully constructed stainless steel honeycomb structures significantly curtails the need for replacement, reducing waste and resource consumption. As experts in material science continue to push the boundaries of what's possible with stainless steel honeycomb structures, industries must keep pace with these advancements to fully exploit the advantages they offer. It's crucial for businesses to align with manufacturers who not only have the technical expertise but also adhere to strict quality control standards to ensure the integrity of the stainless steel used. Trustworthiness in sourcing and manufacturing processes directly correlates with the performance and longevity of the end product. With a proven track record and ongoing advancements, stainless steel honeycomb structures are poised to become a staple in modern design and manufacturing. Industries that embrace this innovative material will benefit not only from its practical applications and aesthetic qualities but also from its alignment with sustainable practices. Therefore, understanding and integrating stainless steel honeycomb panels into relevant areas of application is a strategic move for any forward-thinking organization aiming to enhance performance while supporting environmental stewardship.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025