- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 21, 2025 04:14

Back to list

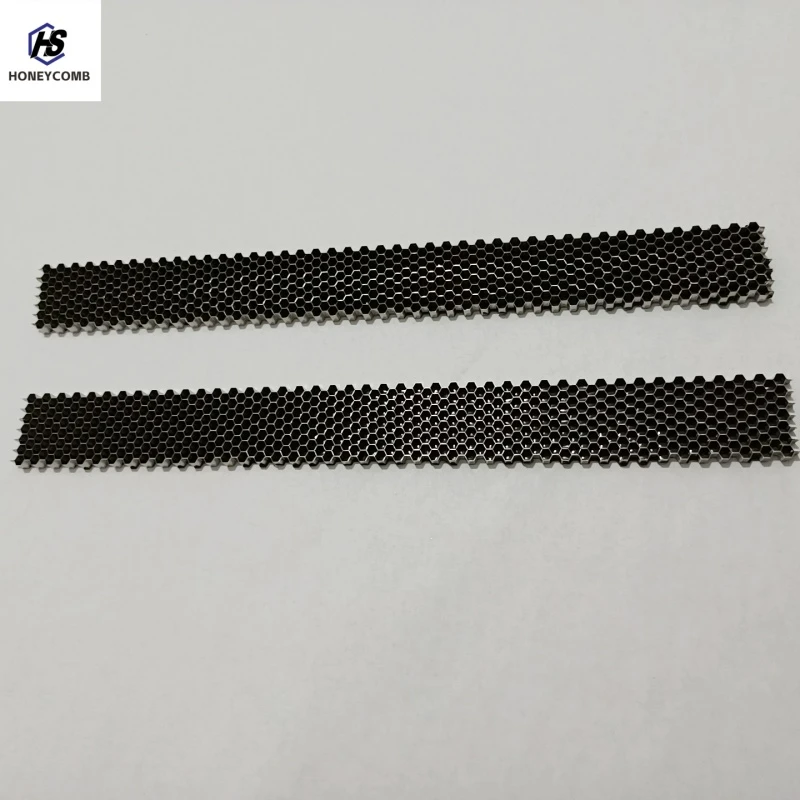

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent

The world of industrial manufacturing and digital fabrication constantly advances, pushing the boundaries of what is possible with traditional machinery. Among these innovations, the stalen honingraatlaserbed—a steel honeycomb laser bed—stands out as a crucial component in laser cutting and engraving technology. This article delves into the various aspects of the stalen honingraatlaserbed, offering insights into its application, advantages, and what users can expect when incorporating this technology into their processes.

Trustworthiness of a product is often established through user testimonials and consistent performance. Users of steel honeycomb laser beds frequently express satisfaction in terms of safety and reliability. The ability of these beds to handle high-intensity laser operations without degradation over time has made them a trustworthy addition to workshops and factories alike. Safety is further ensured as the design minimizes the risks of laser deflection—a crucial factor in maintaining a secure working environment. To truly leverage the benefits of a stalen honingraatlaserbed, understanding its capabilities within specific industrial contexts is essential. As global manufacturing trends tilt towards sustainability and resource efficiency, this technology offers an important advantage by maximizing material utilization and minimizing waste. Companies focused on green manufacturing processes find these laser beds align well with their goals, supporting clean cuts that require less post-processing, thus saving energy and reducing carbon footprints. In conclusion, the stalen honingraatlaserbed is more than just a component of laser cutting machinery; it is an integral part of achieving high efficiency and precision in modern manufacturing processes. Its design inherently supports sustainability, safety, and productivity, making it an invaluable asset across various industrial applications. Embracing this innovative technology can provide a competitive edge, offering opportunities to push the boundaries of design and production capabilities while ensuring the highest standards of quality and reliability.

Trustworthiness of a product is often established through user testimonials and consistent performance. Users of steel honeycomb laser beds frequently express satisfaction in terms of safety and reliability. The ability of these beds to handle high-intensity laser operations without degradation over time has made them a trustworthy addition to workshops and factories alike. Safety is further ensured as the design minimizes the risks of laser deflection—a crucial factor in maintaining a secure working environment. To truly leverage the benefits of a stalen honingraatlaserbed, understanding its capabilities within specific industrial contexts is essential. As global manufacturing trends tilt towards sustainability and resource efficiency, this technology offers an important advantage by maximizing material utilization and minimizing waste. Companies focused on green manufacturing processes find these laser beds align well with their goals, supporting clean cuts that require less post-processing, thus saving energy and reducing carbon footprints. In conclusion, the stalen honingraatlaserbed is more than just a component of laser cutting machinery; it is an integral part of achieving high efficiency and precision in modern manufacturing processes. Its design inherently supports sustainability, safety, and productivity, making it an invaluable asset across various industrial applications. Embracing this innovative technology can provide a competitive edge, offering opportunities to push the boundaries of design and production capabilities while ensuring the highest standards of quality and reliability.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025