- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 05, 2025 05:04

Back to list

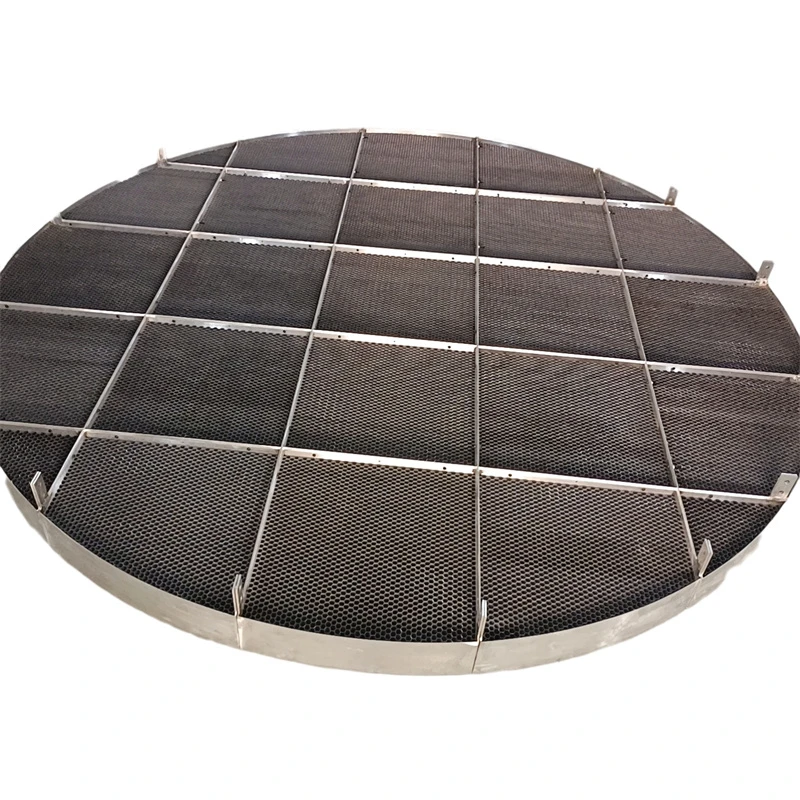

20mm Core Size Stainless Steel Honeycomb Core Panel - Customized for Wind Tunnel Applications

Waveguide honeycomb air vents represent a technological innovation that has gained substantial traction within the technology and engineering sectors. Known for their advanced design and astonishing efficiencies, these components have become pivotal in elevating the performance and functional stability of various high-frequency applications.

Establishing Authoritativeness Industry standards and rigorous testing protocols underscore the efficacy of waveguide honeycomb air vents. Their design has been crafted in accordance with MIL-STD-461 and other electromagnetic compliance standards, assuring stakeholders of their undeniable reliability. These components have earned a stalwart reputation amongst high-frequency design engineers, who vouch for their role in safeguarding sensitive equipment from external electromagnetic interference, which could otherwise compromise data integrity and device performance. Ensuring Trustworthiness The trust in waveguide honeycomb air vents is further amplified through continuous innovation and feedback loops with end-users. Manufacturers routinely engage with clients to integrate industry feedback, enabling iterative improvements that enhance product life cycle and adaptability to different operational environments. Certifications from independent testing bodies add an additional layer of assurance, providing users with confidence that every vent performs to the specification it was designed to meet. In the realm of product applications, waveguide honeycomb air vents are not just passive components but active contributors to the technological ecosystem. They fortify the integrity of high-frequency systems, delivering unbeatable performance that is critical in areas where precision and reliability are non-negotiable. From space missions to secure data centers, the deployment of these advanced air vents ensures peak performance and operational resilience.

Establishing Authoritativeness Industry standards and rigorous testing protocols underscore the efficacy of waveguide honeycomb air vents. Their design has been crafted in accordance with MIL-STD-461 and other electromagnetic compliance standards, assuring stakeholders of their undeniable reliability. These components have earned a stalwart reputation amongst high-frequency design engineers, who vouch for their role in safeguarding sensitive equipment from external electromagnetic interference, which could otherwise compromise data integrity and device performance. Ensuring Trustworthiness The trust in waveguide honeycomb air vents is further amplified through continuous innovation and feedback loops with end-users. Manufacturers routinely engage with clients to integrate industry feedback, enabling iterative improvements that enhance product life cycle and adaptability to different operational environments. Certifications from independent testing bodies add an additional layer of assurance, providing users with confidence that every vent performs to the specification it was designed to meet. In the realm of product applications, waveguide honeycomb air vents are not just passive components but active contributors to the technological ecosystem. They fortify the integrity of high-frequency systems, delivering unbeatable performance that is critical in areas where precision and reliability are non-negotiable. From space missions to secure data centers, the deployment of these advanced air vents ensures peak performance and operational resilience.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025