- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 29, 2025 02:45

Back to list

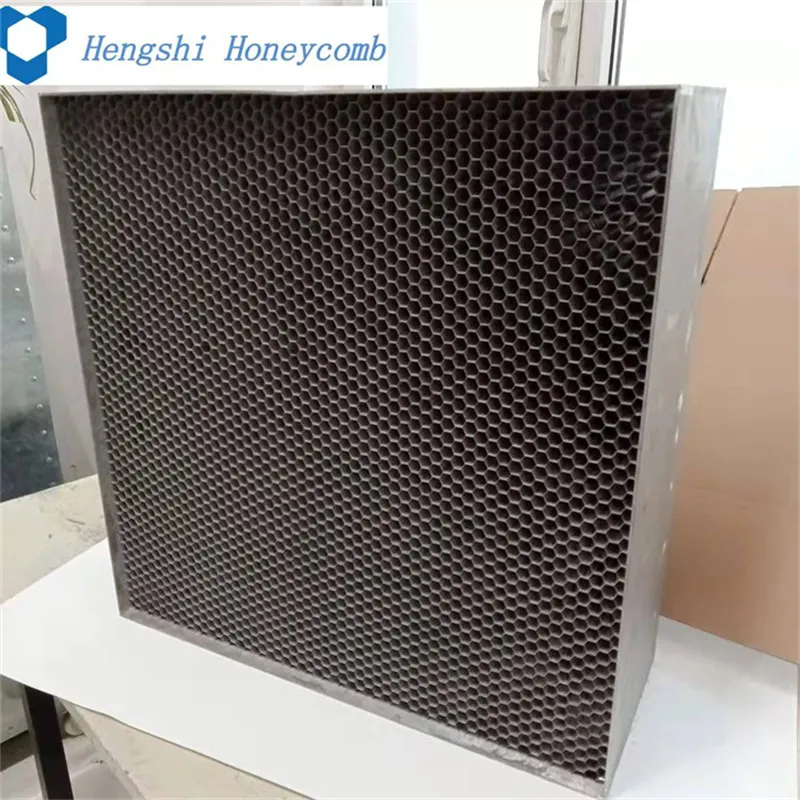

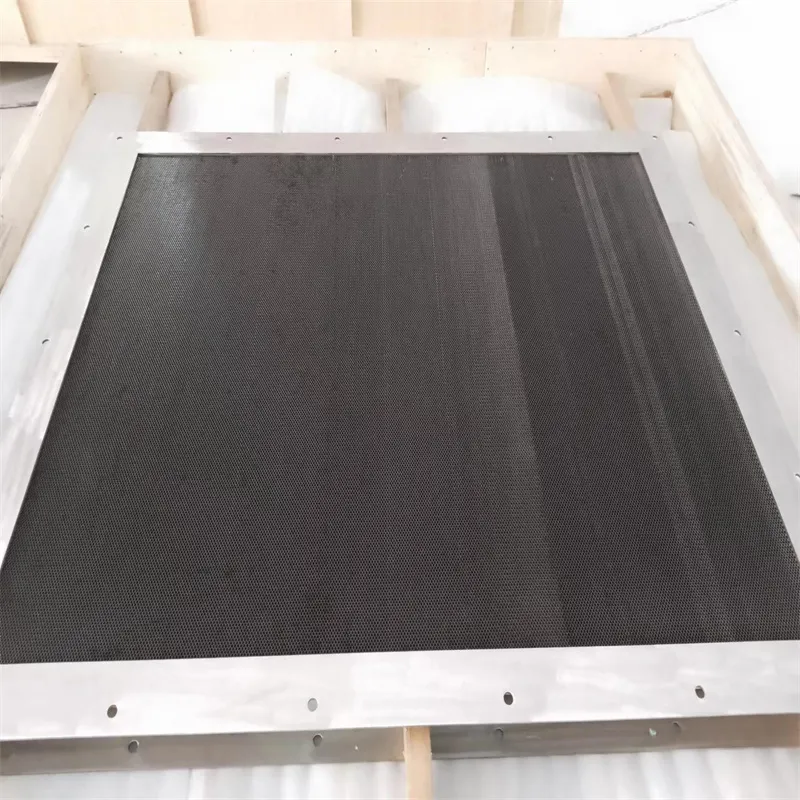

intake air straightener

Stainless steel honeycomb supports have emerged as an innovative solution within various industries, offering unparalleled advantages in terms of strength, durability, and versatility. Engineered with precision, these supports are designed to withstand the most demanding conditions, offering superior performance that meets the rigorous requirements of diverse applications.

Automotive developers continuously seek materials that enhance performance while ensuring safety. Stainless steel honeycomb supports play an integral role in this pursuit. They contribute significantly to the development of safer, more efficient vehicles. Their ability to absorb energy during collisions has been cited in several safety studies, underscoring their effectiveness in reducing vehicular damage and passenger injury. Manufacturers who have adopted stainless steel honeycomb supports in their product lines have reported a notable increase in product longevity and reliability. The enduring nature of stainless steel means reduced maintenance costs and longer service life, drawing the attention of companies focused on sustainable practices. This aligns with the global shift towards eco-friendly product development, reinforcing the authoritative stance of stainless steel honeycomb supports on both resilience and sustainability. The trustworthiness of companies specializing in these advanced materials can be gauged by their adherence to industry standards and certifications. Companies that invest in comprehensive testing procedures and maintain transparency in their sourcing and production processes solidify their reputation as leaders in the industry. Customers and partners repeatedly stress the importance of these factors, as it reassures them of the product’s quality and the company’s commitment to excellence. In conclusion, stainless steel honeycomb supports represent a leap forward in material science and engineering. Through expert knowledge and proven experience, these supports provide unparalleled benefits across various industries. Professionals worldwide acknowledge their authority in enhancing design possibilities and improving product performance, remaining a steadfast choice for those seeking reliability and innovation. As industries continue to evolve, the application of stainless steel honeycomb supports is expected to expand, driving further advancements in technology and design.

Automotive developers continuously seek materials that enhance performance while ensuring safety. Stainless steel honeycomb supports play an integral role in this pursuit. They contribute significantly to the development of safer, more efficient vehicles. Their ability to absorb energy during collisions has been cited in several safety studies, underscoring their effectiveness in reducing vehicular damage and passenger injury. Manufacturers who have adopted stainless steel honeycomb supports in their product lines have reported a notable increase in product longevity and reliability. The enduring nature of stainless steel means reduced maintenance costs and longer service life, drawing the attention of companies focused on sustainable practices. This aligns with the global shift towards eco-friendly product development, reinforcing the authoritative stance of stainless steel honeycomb supports on both resilience and sustainability. The trustworthiness of companies specializing in these advanced materials can be gauged by their adherence to industry standards and certifications. Companies that invest in comprehensive testing procedures and maintain transparency in their sourcing and production processes solidify their reputation as leaders in the industry. Customers and partners repeatedly stress the importance of these factors, as it reassures them of the product’s quality and the company’s commitment to excellence. In conclusion, stainless steel honeycomb supports represent a leap forward in material science and engineering. Through expert knowledge and proven experience, these supports provide unparalleled benefits across various industries. Professionals worldwide acknowledge their authority in enhancing design possibilities and improving product performance, remaining a steadfast choice for those seeking reliability and innovation. As industries continue to evolve, the application of stainless steel honeycomb supports is expected to expand, driving further advancements in technology and design.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025