- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 29, 2025 02:23

Back to list

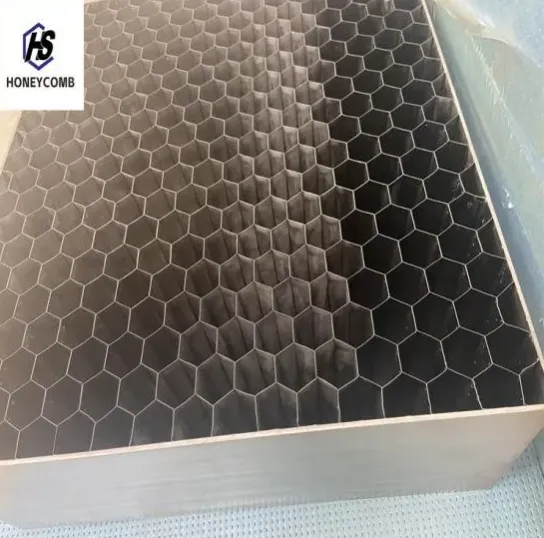

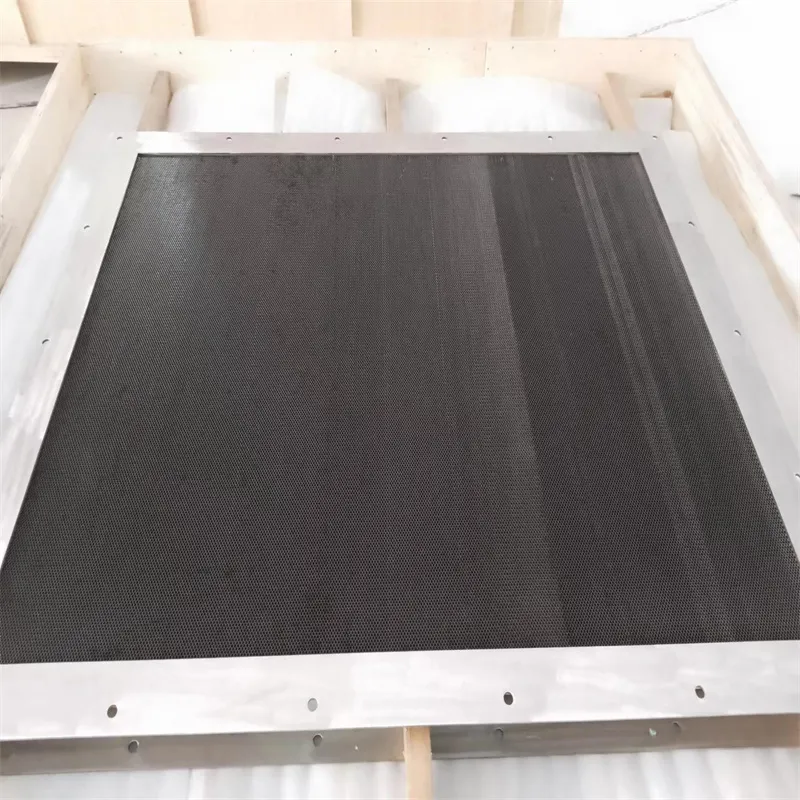

honeycomb seals

The stainless steel honeycomb sandwich panel is an innovative product that has redefined standards in architectural design and construction. Boasting a unique combination of strength, aesthetics, and versatility, these panels are increasingly being chosen for a wide array of applications ranging from aerospace to modern architecture.

The authority of stainless steel honeycomb sandwich panels is evidenced by their widespread adoption in prestigious projects globally. Used in automotive, marine, and rail industries, these panels have been proven to enhance safety and operational efficiency. In architecture, their application ranges from curtain walls and partitions to ceilings and facades. These panels are not only functional but also offer a sleek, modern appearance, contributing to a polished aesthetic in contemporary design. Trust in stainless steel honeycomb sandwich panels stems from rigorous testing and certification processes they undergo before reaching the market. Many of these panels comply with stringent international standards for fire resistance, thermal performance, and acoustic insulation. Such certifications assure architects and engineers of their reliability and effectiveness in even the most challenging conditions. Users can feel confident in their choice, knowing that these panels will maintain structural integrity and meet performance expectations over time. In conclusion, the stainless steel honeycomb sandwich panel is a testament to the advancements in material science and engineering. Its unmatched combination of lightweight strength, durability, and design adaptability makes it a preferred solution for modern construction challenges. By embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, this product stands out in the construction materials market, paving the way for future innovations in smart building solutions.

The authority of stainless steel honeycomb sandwich panels is evidenced by their widespread adoption in prestigious projects globally. Used in automotive, marine, and rail industries, these panels have been proven to enhance safety and operational efficiency. In architecture, their application ranges from curtain walls and partitions to ceilings and facades. These panels are not only functional but also offer a sleek, modern appearance, contributing to a polished aesthetic in contemporary design. Trust in stainless steel honeycomb sandwich panels stems from rigorous testing and certification processes they undergo before reaching the market. Many of these panels comply with stringent international standards for fire resistance, thermal performance, and acoustic insulation. Such certifications assure architects and engineers of their reliability and effectiveness in even the most challenging conditions. Users can feel confident in their choice, knowing that these panels will maintain structural integrity and meet performance expectations over time. In conclusion, the stainless steel honeycomb sandwich panel is a testament to the advancements in material science and engineering. Its unmatched combination of lightweight strength, durability, and design adaptability makes it a preferred solution for modern construction challenges. By embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, this product stands out in the construction materials market, paving the way for future innovations in smart building solutions.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025