- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 08:23

Back to list

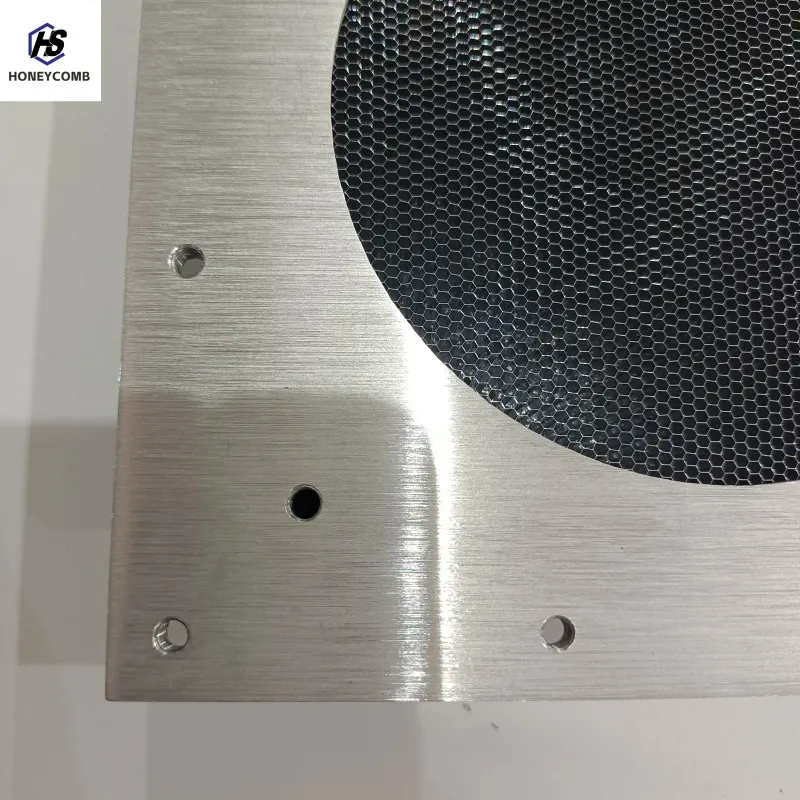

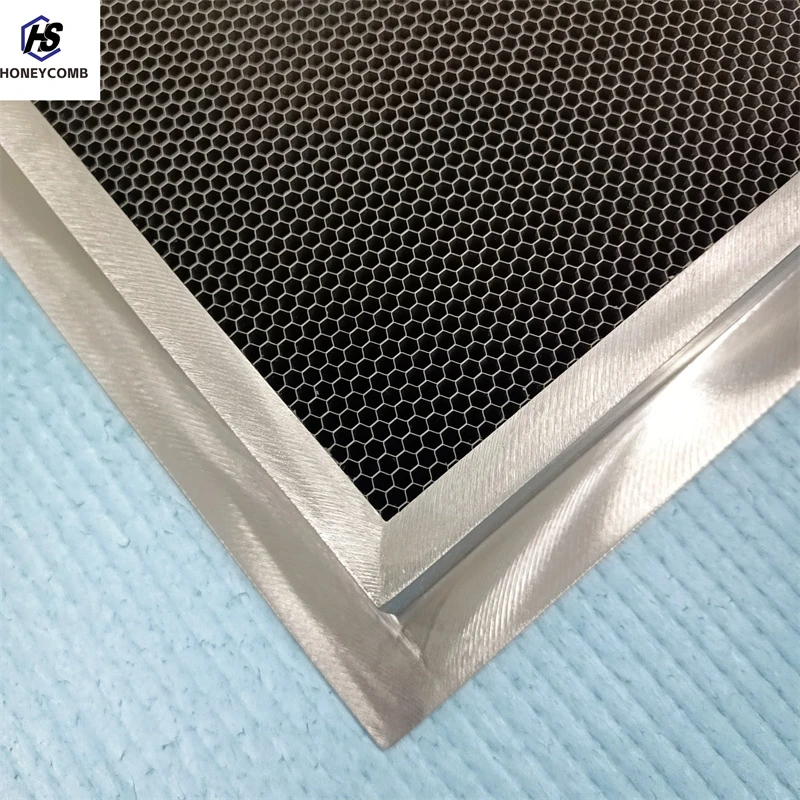

Honeycomb Stainless Steel Air Flow Straightener / Steel Honeycomb Wind Tunnel

Honeycomb panels have revolutionized the way industries approach materials for construction, transportation, and design. Derived from natural sources, honeycomb core panels boast impressive strength-to-weight ratios, making them ideal for applications where reducing weight without compromising structural integrity is vital. This article delves into the unique benefits and uses of honeycomb panels, outlining why they are an unparalleled choice in various sectors.

Building trust with honeycomb panel technology involves acknowledging both its proven track record and its potential for future innovations. Users across industries report a consistent reliability of honeycomb panels due to their inherent structural benefits, resistance to corrosion, and thermal insulation properties. This trust is further reinforced by stringent testing and quality assurance standards that honeycomb panels undergo, ensuring they meet international safety and performance measures. From a practical standpoint, the application of honeycomb panels extends beyond industrial uses. In renewable energy, specifically solar panel installations, these panels serve as robust backings that support and protect cells, optimizing performance and lifespan. The architectural industry also appreciates the aesthetic flexibility of honeycomb panels, using them in creative ways to achieve modern, sustainable designs without sacrificing strength. In conclusion, honeycomb panels represent more than just an alternative to traditional materials—they symbolize an evolution in material science that prioritizes performance, sustainability, and cost-effectiveness. Their widespread application and growing popularity across multiple sectors are a testament to their effectiveness. For businesses looking to enhance product offerings or improve existing processes, investing in honeycomb panels is not merely a consideration but a step toward innovation in material use. As industries continue to seek new ways to optimize productivity and sustainability, the reliance on the exceptional characteristics of honeycomb panel technology is expected to surge, paving the way for new developments and applications in the years to come.

Building trust with honeycomb panel technology involves acknowledging both its proven track record and its potential for future innovations. Users across industries report a consistent reliability of honeycomb panels due to their inherent structural benefits, resistance to corrosion, and thermal insulation properties. This trust is further reinforced by stringent testing and quality assurance standards that honeycomb panels undergo, ensuring they meet international safety and performance measures. From a practical standpoint, the application of honeycomb panels extends beyond industrial uses. In renewable energy, specifically solar panel installations, these panels serve as robust backings that support and protect cells, optimizing performance and lifespan. The architectural industry also appreciates the aesthetic flexibility of honeycomb panels, using them in creative ways to achieve modern, sustainable designs without sacrificing strength. In conclusion, honeycomb panels represent more than just an alternative to traditional materials—they symbolize an evolution in material science that prioritizes performance, sustainability, and cost-effectiveness. Their widespread application and growing popularity across multiple sectors are a testament to their effectiveness. For businesses looking to enhance product offerings or improve existing processes, investing in honeycomb panels is not merely a consideration but a step toward innovation in material use. As industries continue to seek new ways to optimize productivity and sustainability, the reliance on the exceptional characteristics of honeycomb panel technology is expected to surge, paving the way for new developments and applications in the years to come.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025