- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 07:55

Back to list

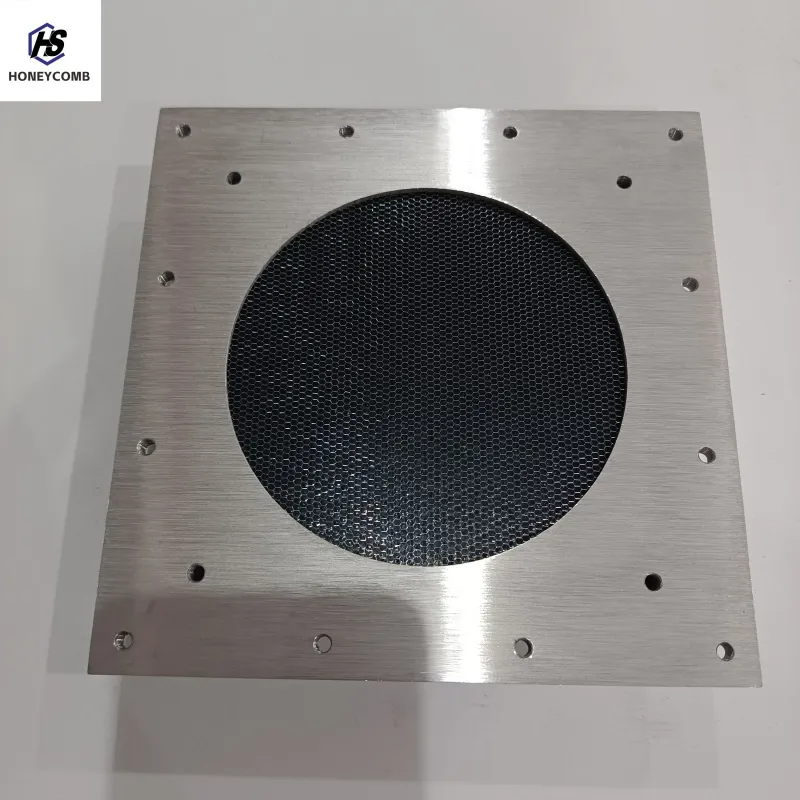

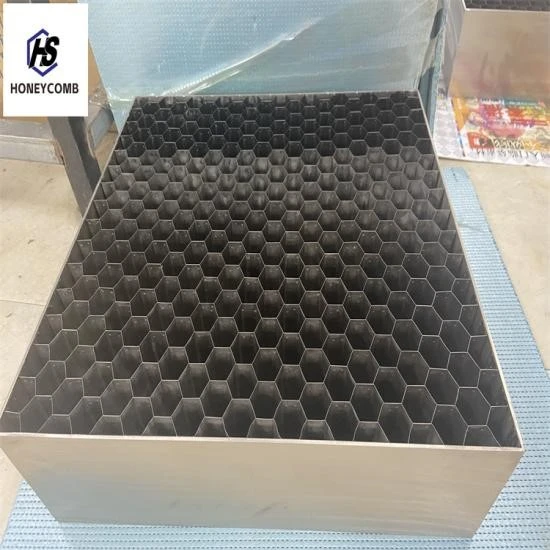

Hengshi Honeycomb Customized Honeycomb Air Straightenerflow Straightener

Navigating the market of construction and design materials can often be a daunting task. One such material gaining traction for its unique properties and versatile applications is the stalen honingraat plaat, or steel honeycomb panel. This innovative material blends modern technology with engineering precision, setting a new benchmark for future construction endeavors.

Additionally, the aesthetic potential of stalen honingraat platen should not be underestimated. The sleek, modern finish they offer can be customized to fit varying design prerequisites, catering to a broad spectrum of architectural visions. Whether it’s a contemporary office space or a revamped industrial abode, these panels adapt to diverse design languages with ease. Professionals who have adopted this material universally answer queries with high regard. Their expertise suggests that this material not only fulfills current needs but also prepares the industry for future trends by allowing innovative performance under varying conditions. Research confirms the durability and safety of such panels in earthquake-prone areas and during fire incidents, offering an additional layer of trust and assurance. However, like all engineering solutions, maximizing the utility of steel honeycomb panels requires precise planning and skilled installation. Experts urge consultation with experienced engineers to ensure the best outcomes, harnessing the material’s properties to the fullest while avoiding potential pitfalls associated with improper use. The stalen honingraat plaat’s array of attributes is culminating in expanded usage across industries. Companies specializing in civil, architectural, and aerospace applications continually push the boundaries of its capabilities, expanding its influence. From car manufacturers seeking lightweight yet reliable materials to tech firms designing cooler, aesthetically superior office interiors, the potential seems limitless. To wrap up, the stalen honingraat plaat represents a convergence of technology, efficiency, and aesthetic flexibility. Its presence in present-day design and construction is a testament to its potential, underscoring an emergence into a new era of building materials. By engaging with trusted suppliers and valuing expert advice during application, stakeholders can unlock its full potential, paving the way for a sustainable and innovative future.

Additionally, the aesthetic potential of stalen honingraat platen should not be underestimated. The sleek, modern finish they offer can be customized to fit varying design prerequisites, catering to a broad spectrum of architectural visions. Whether it’s a contemporary office space or a revamped industrial abode, these panels adapt to diverse design languages with ease. Professionals who have adopted this material universally answer queries with high regard. Their expertise suggests that this material not only fulfills current needs but also prepares the industry for future trends by allowing innovative performance under varying conditions. Research confirms the durability and safety of such panels in earthquake-prone areas and during fire incidents, offering an additional layer of trust and assurance. However, like all engineering solutions, maximizing the utility of steel honeycomb panels requires precise planning and skilled installation. Experts urge consultation with experienced engineers to ensure the best outcomes, harnessing the material’s properties to the fullest while avoiding potential pitfalls associated with improper use. The stalen honingraat plaat’s array of attributes is culminating in expanded usage across industries. Companies specializing in civil, architectural, and aerospace applications continually push the boundaries of its capabilities, expanding its influence. From car manufacturers seeking lightweight yet reliable materials to tech firms designing cooler, aesthetically superior office interiors, the potential seems limitless. To wrap up, the stalen honingraat plaat represents a convergence of technology, efficiency, and aesthetic flexibility. Its presence in present-day design and construction is a testament to its potential, underscoring an emergence into a new era of building materials. By engaging with trusted suppliers and valuing expert advice during application, stakeholders can unlock its full potential, paving the way for a sustainable and innovative future.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025