- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 07, 2025 02:02

Back to list

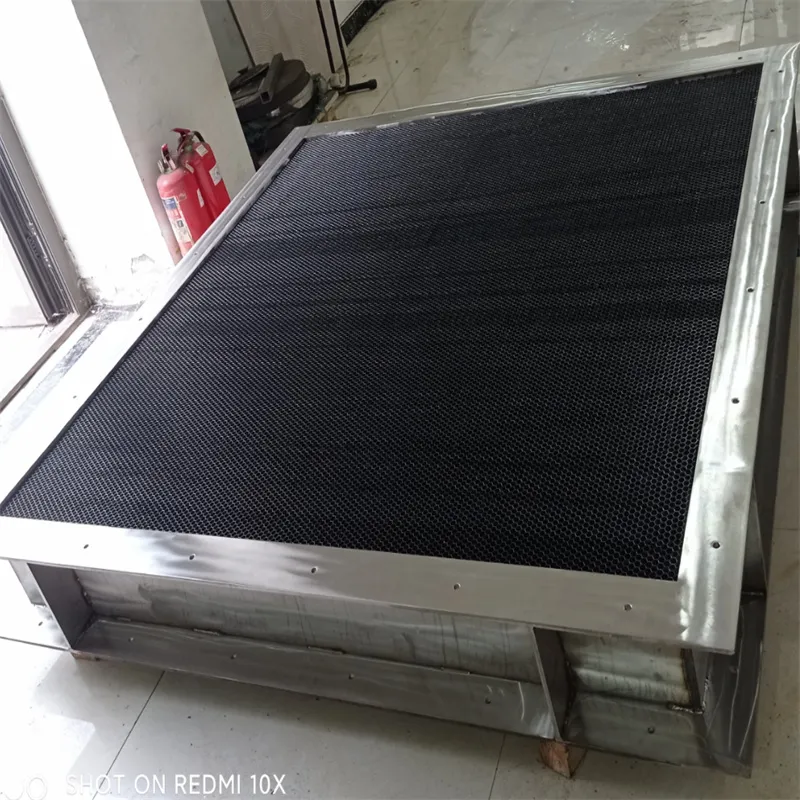

steel honeycomb core

When exploring the cutting-edge technology of material engineering, the steel honeycomb core stands out as a quintessential example of innovation and versatility. This unique structure is characterized by its hexagonal pattern, mimicking the natural design of a honeycomb, which translates into unparalleled strength and efficiency. As industries worldwide progress toward more sustainable and efficient materials, the steel honeycomb core emerges as a superior option.

In terms of manufacturing expertise, producing a steel honeycomb core demands a high degree of precision and technical know-how. The process involves the expansion or corrugation of metal sheets, followed by bonding layers to form the patented honeycomb structure. Manufacturers specialized in this technique ensure that the structural properties of the honeycomb are preserved, resulting in high-quality materials suitable for demanding applications. The authority and trustworthiness associated with steel honeycomb cores are underscored by their adoption in notable projects worldwide. Leading brands across various sectors have successfully implemented these cores, attesting to their reliability and effectiveness. Additionally, certifications from industry standards such as ISO further validate their credibility, ensuring that end-users receive products that meet or exceed expectations. Transparency in sourcing and sustainability are additional factors contributing to the steel honeycomb core's trustworthiness. Manufacturers often source high-grade steel compliant with environmental regulations, ensuring that the final products contribute to broader sustainability goals. This transparency builds consumer trust, as stakeholders can be assured of an environmentally-responsible product lifecycle. In conclusion, the steel honeycomb core represents a cornerstone of modern material innovation, distinguished by its robust performance and adaptability across industries. As technology continues to advance, the adoption of such highly engineered solutions is set to expand, driven by the constant pursuit of efficiency and sustainability. This evolution signifies a promising future where products are not only lighter and stronger but also more attuned to the environmental and economic demands of our age.

In terms of manufacturing expertise, producing a steel honeycomb core demands a high degree of precision and technical know-how. The process involves the expansion or corrugation of metal sheets, followed by bonding layers to form the patented honeycomb structure. Manufacturers specialized in this technique ensure that the structural properties of the honeycomb are preserved, resulting in high-quality materials suitable for demanding applications. The authority and trustworthiness associated with steel honeycomb cores are underscored by their adoption in notable projects worldwide. Leading brands across various sectors have successfully implemented these cores, attesting to their reliability and effectiveness. Additionally, certifications from industry standards such as ISO further validate their credibility, ensuring that end-users receive products that meet or exceed expectations. Transparency in sourcing and sustainability are additional factors contributing to the steel honeycomb core's trustworthiness. Manufacturers often source high-grade steel compliant with environmental regulations, ensuring that the final products contribute to broader sustainability goals. This transparency builds consumer trust, as stakeholders can be assured of an environmentally-responsible product lifecycle. In conclusion, the steel honeycomb core represents a cornerstone of modern material innovation, distinguished by its robust performance and adaptability across industries. As technology continues to advance, the adoption of such highly engineered solutions is set to expand, driven by the constant pursuit of efficiency and sustainability. This evolution signifies a promising future where products are not only lighter and stronger but also more attuned to the environmental and economic demands of our age.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025