- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 08, 2025 03:00

Back to list

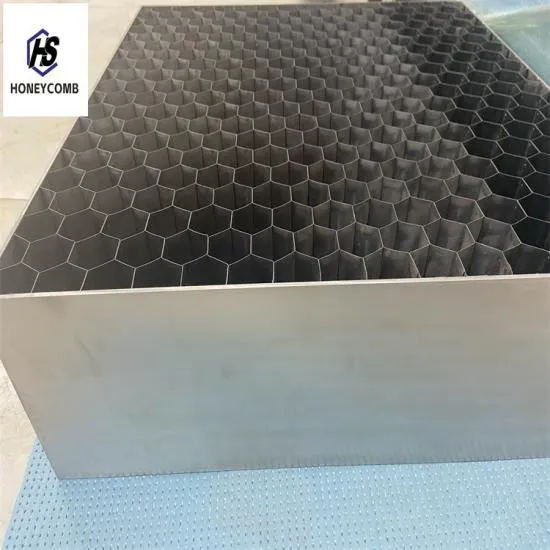

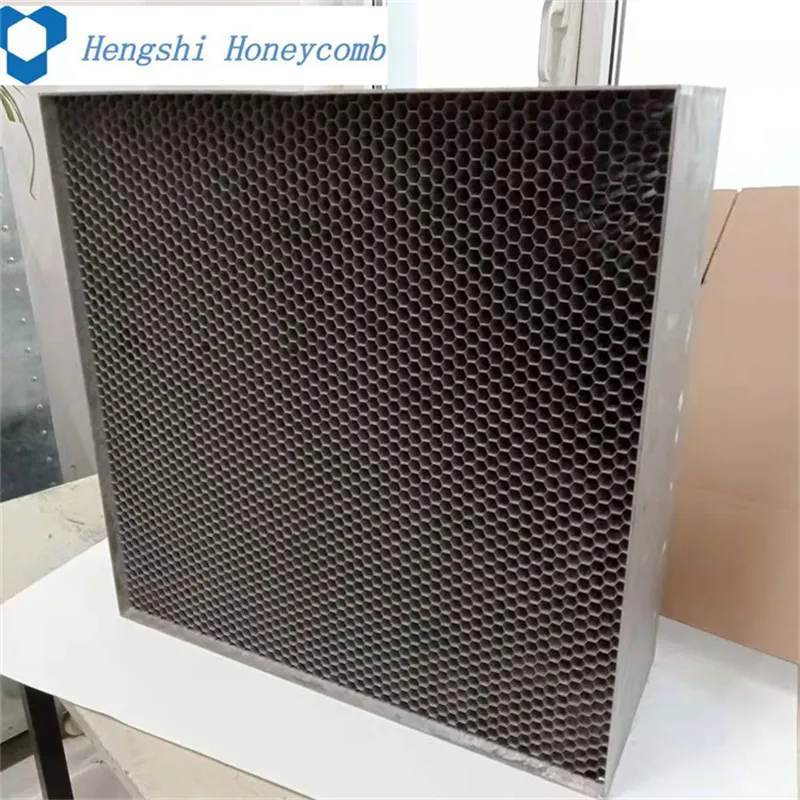

steel honeycomb laser bed

The steel honeycomb laser bed has become a cornerstone in the realm of manufacturing, offering unparalleled benefits that make it an indispensable component for various industries. The intricate design of the honeycomb framework, combined with the robust nature of steel, provides a perfect synergy that enhances precision and efficiency in laser cutting applications.

When considering the authoritativeness of using a steel honeycomb laser bed, it’s important to note that renowned laser cutting machine manufacturers highly recommend these types of beds for professional-grade machines. They recognize the high-performance outcomes and cost-effectiveness in terms of reduced material wastage and enhanced cutting speed and accuracy. Many leading industry professionals endorse these beds in trade publications and industry seminars, further establishing their credibility. Trust in these steel honeycomb structures stems from their proven track record in various industry applications. They have undergone extensive testing in real-world settings, consistently demonstrating their reliability under different operational conditions. Industry regulations and quality standards also back their usage, adding an extra layer of trust for companies that prioritize compliance and safety. In conclusion, embracing the innovative characteristics of the steel honeycomb laser bed can significantly optimize efficiency and precision in laser cutting processes. This component is not just a bed; it serves as a strategic investment that delivers enhanced operational outcomes, providing businesses with the competitive edge necessary in today’s precision-driven markets. As technology advances, these laser beds will remain vital in supporting cutting technologies, ensuring companies meet and exceed market demands efficiently.

When considering the authoritativeness of using a steel honeycomb laser bed, it’s important to note that renowned laser cutting machine manufacturers highly recommend these types of beds for professional-grade machines. They recognize the high-performance outcomes and cost-effectiveness in terms of reduced material wastage and enhanced cutting speed and accuracy. Many leading industry professionals endorse these beds in trade publications and industry seminars, further establishing their credibility. Trust in these steel honeycomb structures stems from their proven track record in various industry applications. They have undergone extensive testing in real-world settings, consistently demonstrating their reliability under different operational conditions. Industry regulations and quality standards also back their usage, adding an extra layer of trust for companies that prioritize compliance and safety. In conclusion, embracing the innovative characteristics of the steel honeycomb laser bed can significantly optimize efficiency and precision in laser cutting processes. This component is not just a bed; it serves as a strategic investment that delivers enhanced operational outcomes, providing businesses with the competitive edge necessary in today’s precision-driven markets. As technology advances, these laser beds will remain vital in supporting cutting technologies, ensuring companies meet and exceed market demands efficiently.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025