- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 11:01

Back to list

struttura a nido d'ape in alluminio

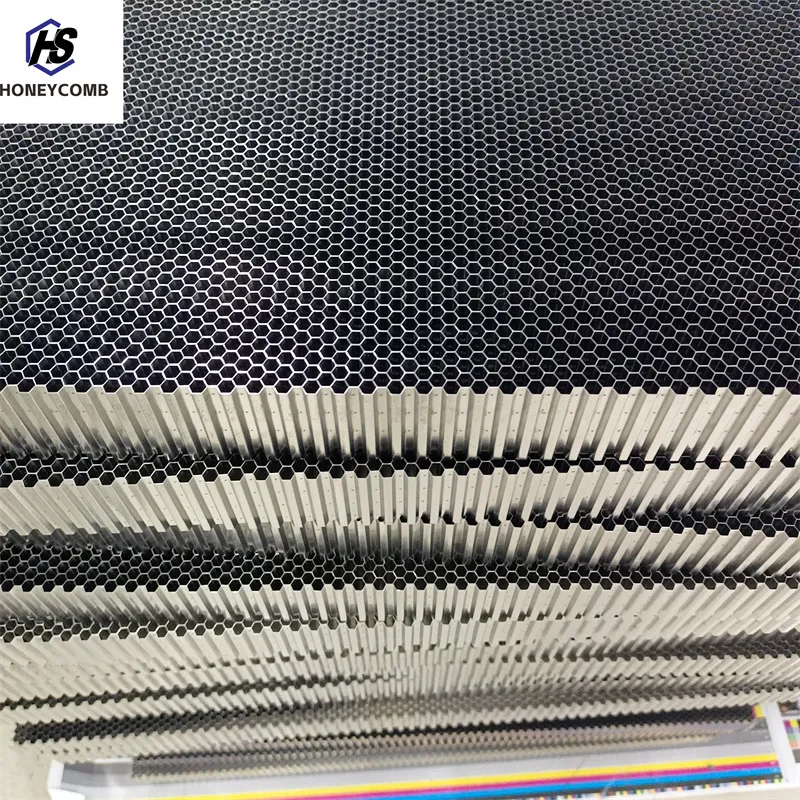

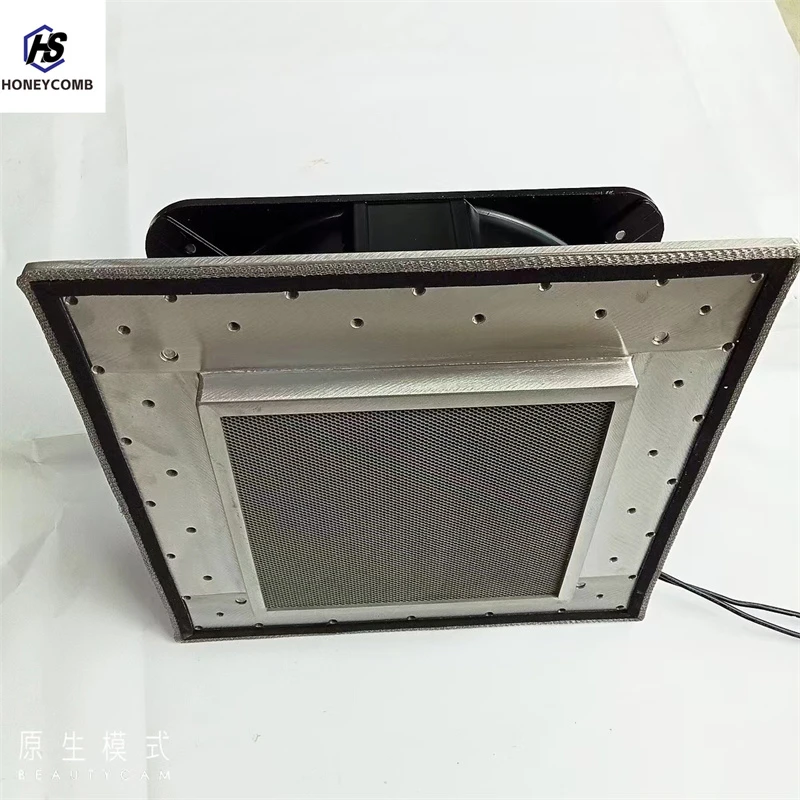

Aluminum honeycomb structures are revolutionizing various industries with their unique combination of light weight, high strength, and versatility. As experts in the field of material engineering can attest, this innovative design is increasingly becoming crucial in applications ranging from aerospace to construction, owing to its advanced technological properties.

For those venturing into industries where material innovation is key, understanding the potential of aluminum honeycomb structures can provide a competitive edge. Engineers and designers have lauded the ease with which these panels can be customized to specific requirements, whether that entails altering the cell size, the thickness of the cell walls, or the overall dimension of the panels. This adaptability allows for creation of tailored solutions that meet precise performance criteria and aesthetic demands. In terms of installation, the feedback from construction experts reinforces the value of aluminum honeycomb structures in streamlining project workflows. The panels are easy to handle and can be prefabricated to exact specifications, minimizing on-site adjustments. This reduction in complexity and time spent on installation not only accelerates project timelines but also decreases overall construction costs, which is a critical consideration in large-scale developments. The versatility of aluminum honeycomb structures extends to their applications in the transportation sector as well. Leading automotive companies are increasingly incorporating these panels into vehicle designs to enhance safety while boosting fuel efficiency. The panels' high energy absorption capacity is particularly beneficial in improving vehicle crashworthiness, protecting passengers effectively in the event of a collision. As technological advancements continue to push the boundaries of engineering, the use of aluminum honeycomb structures is expected to grow exponentially. Industry experts anticipate further innovations in customization and performance enhancements, driven by advancements in manufacturing technologies. As we move towards an era where efficiency and sustainability are paramount, the role of advanced materials like aluminum honeycomb will continue to expand, defining the future of efficient design and construction. The reliability and resilience of aluminum honeycomb structures ensure their position at the forefront of modern material solutions. With an unwavering commitment to quality and innovation, manufacturers are setting new standards in product performance, offering clients unmatched expertise and authority in engineering excellence. This unwavering trust in aluminum honeycomb structures will undoubtedly continue to shape the landscape of global industries.

For those venturing into industries where material innovation is key, understanding the potential of aluminum honeycomb structures can provide a competitive edge. Engineers and designers have lauded the ease with which these panels can be customized to specific requirements, whether that entails altering the cell size, the thickness of the cell walls, or the overall dimension of the panels. This adaptability allows for creation of tailored solutions that meet precise performance criteria and aesthetic demands. In terms of installation, the feedback from construction experts reinforces the value of aluminum honeycomb structures in streamlining project workflows. The panels are easy to handle and can be prefabricated to exact specifications, minimizing on-site adjustments. This reduction in complexity and time spent on installation not only accelerates project timelines but also decreases overall construction costs, which is a critical consideration in large-scale developments. The versatility of aluminum honeycomb structures extends to their applications in the transportation sector as well. Leading automotive companies are increasingly incorporating these panels into vehicle designs to enhance safety while boosting fuel efficiency. The panels' high energy absorption capacity is particularly beneficial in improving vehicle crashworthiness, protecting passengers effectively in the event of a collision. As technological advancements continue to push the boundaries of engineering, the use of aluminum honeycomb structures is expected to grow exponentially. Industry experts anticipate further innovations in customization and performance enhancements, driven by advancements in manufacturing technologies. As we move towards an era where efficiency and sustainability are paramount, the role of advanced materials like aluminum honeycomb will continue to expand, defining the future of efficient design and construction. The reliability and resilience of aluminum honeycomb structures ensure their position at the forefront of modern material solutions. With an unwavering commitment to quality and innovation, manufacturers are setting new standards in product performance, offering clients unmatched expertise and authority in engineering excellence. This unwavering trust in aluminum honeycomb structures will undoubtedly continue to shape the landscape of global industries.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025