- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Superior Steel Honeycomb Core for Strength & Lightness

The Strategic Advantage of Steel Honeycomb Core in Modern Engineering

In the realm of advanced material science and engineering, the steel honeycomb core stands as a testament to innovation, offering an unparalleled combination of properties that redefine structural integrity, thermal management, and energy absorption across a multitude of industries. This intricate material, distinguished by its cellular hexagonal structure reminiscent of a beehive, is meticulously engineered to deliver exceptional strength-to-weight ratios, superior stiffness, and remarkable resistance to environmental aggressors. Unlike solid materials, the geometry of a steel honeycomb core maximizes performance while minimizing material usage, leading to significant advantages in weight reduction, which is critical in sectors like aerospace, automotive, and marine. Furthermore, its inherent design facilitates effective energy dissipation, making it an ideal candidate for applications requiring enhanced impact resistance. The demand for lightweight yet robust materials continues to escalate globally, driven by stringent energy efficiency regulations, the imperative for reduced carbon footprints, and the relentless pursuit of higher operational performance. As industries pivot towards sustainable and high-performance solutions, the strategic adoption of advanced materials like the steel honeycomb core becomes not just an option, but a necessity for maintaining competitive edge and driving technological progress. This detailed exposition will delve into the profound impact and versatile applications of this transformative material, highlighting its technical superiority and the specific benefits it offers to diverse industrial challenges, with a particular focus on the specialized application of Customized Hexagonal 316 Stainless Steel Honeycomb Core for advanced sewage treatment systems, demonstrating its adaptability and critical role in modern infrastructure.

The Intricate Manufacturing Journey of a Steel Honeycomb Core

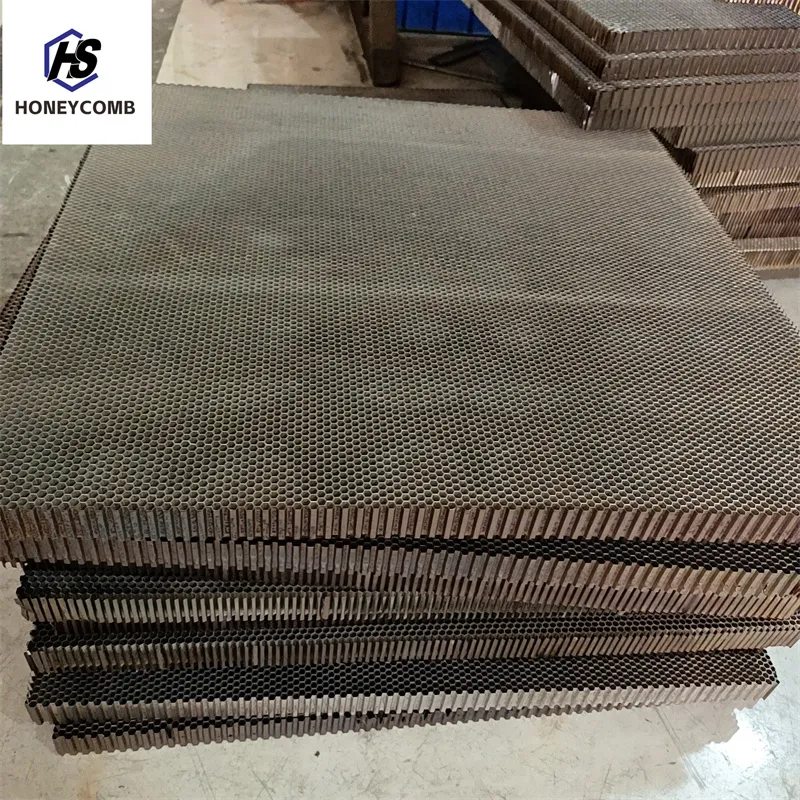

The production of a high-quality steel honeycomb core is a sophisticated process demanding precision, advanced machinery, and rigorous quality control at every stage to ensure the final product meets stringent industry standards for performance and durability. It begins with the meticulous selection of raw materials, typically high-grade stainless steel such as 316, 304, or other specialized alloys, chosen for their specific properties like corrosion resistance, mechanical strength, and weldability relevant to the intended application. For a product like the Customized Hexagonal 316 Stainless Steel Honeycomb Core, the material choice of 316 stainless steel is paramount due to its exceptional resistance to chlorides and other aggressive chemicals found in sewage treatment environments, ensuring a prolonged operational lifespan and minimal maintenance requirements. The manufacturing process generally involves several key steps: initially, thin steel foils are precisely corrugated or crimped into a series of wave-like or angular shapes, forming the characteristic hexagonal cell geometry when combined. These corrugated sheets are then assembled and bonded together through advanced welding techniques, often resistance welding or laser welding, which create robust node bonds between adjacent sheets, forming the cellular structure. This delicate bonding process is critical; insufficient bonding can lead to structural failure, while excessive heat input can compromise material properties. Following the bonding, the unexpanded block of bonded corrugated sheets undergoes an expansion process, where it is carefully stretched perpendicular to the bonding lines to reveal the open honeycomb cells. This expansion requires careful control to maintain cell uniformity and structural integrity. After expansion, the block is then precisely cut to the required thickness and dimensions using advanced CNC machining or abrasive cutting techniques, ensuring tight tolerances for diverse applications. Throughout these stages, adherence to international standards such as ISO 9001 for quality management, ANSI for dimensioning, and ASTM for material testing is non-negotiable. Each batch undergoes rigorous inspection, including visual checks for cell uniformity, dimensional accuracy measurements, and mechanical testing for parameters like compressive and shear strength. The typical lifespan of a high-grade steel honeycomb core, especially one made from 316 stainless steel, can extend for decades, often exceeding 20-30 years in non-extreme environments, making it a highly cost-effective solution over its operational lifecycle. Its application spans across a multitude of industries including petrochemical, metallurgy, water supply and drainage, marine, aerospace, and construction, where its unique combination of strength, lightweight properties, and corrosion resistance offers distinct advantages, leading to significant energy savings through reduced structural weight and enhanced resistance to harsh operating conditions.

Fig 1: Conceptual illustration of the steel honeycomb core manufacturing process, emphasizing precision and material integrity.

Unveiling Technical Parameters and Performance Characteristics

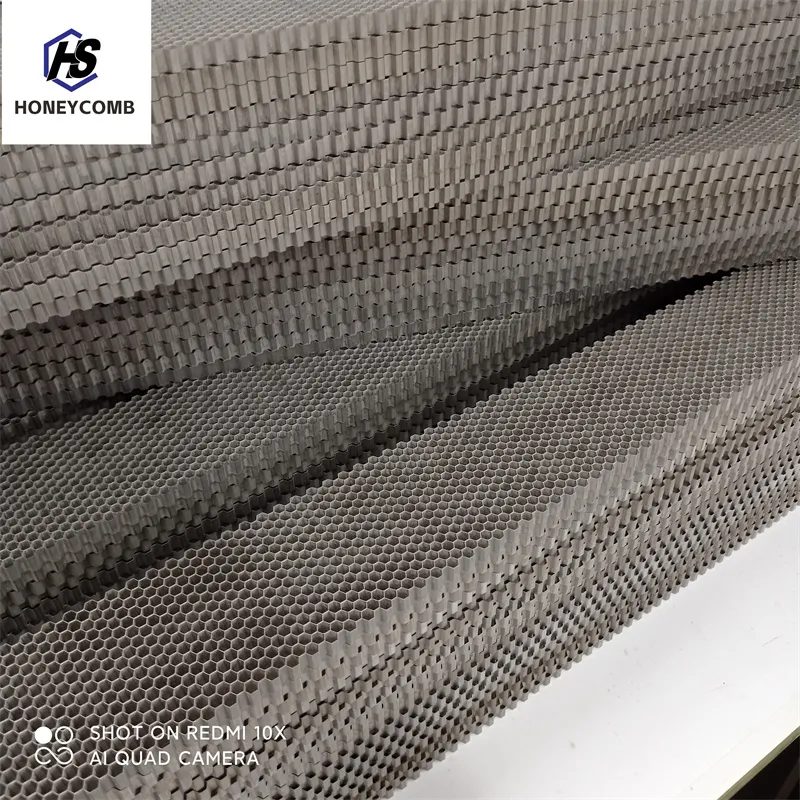

The performance of a steel honeycomb core is directly attributable to a precise set of technical parameters and inherent material characteristics, which collectively define its suitability for demanding applications. Understanding these parameters is crucial for engineers and decision-makers to specify the optimal honeycomb structure for their particular needs. Key mechanical properties include compressive strength, which refers to the material's ability to withstand forces that tend to compress it; shear strength, indicating its resistance to forces acting parallel to its surface; and stiffness, representing its rigidity and resistance to deformation under load. These properties are intrinsically linked to the cell size, foil thickness, and the overall core height. For instance, smaller cell sizes and thicker foils generally yield higher compressive and shear strengths, albeit at a slightly increased weight. Conversely, larger cells with thinner foils can achieve significant weight reduction while maintaining adequate structural integrity for less strenuous applications. Beyond mechanical prowess, thermal conductivity is another critical characteristic, as the cellular structure entraps air within its cells, creating an excellent thermal insulation barrier, which is advantageous in applications requiring thermal management or energy efficiency. Corrosion resistance, particularly for 316 stainless steel variants, is outstanding due to its chromium and molybdenum content, offering superior protection against a wide array of corrosive agents, from saline environments to aggressive chemical solutions, making it indispensable for marine, chemical processing, and wastewater treatment applications. Furthermore, the acoustic dampening properties of a steel honeycomb core are noteworthy; its open cell structure can absorb sound waves, contributing to noise reduction in architectural panels or industrial machinery. The table below outlines typical specifications and performance benchmarks for high-grade stainless steel honeycomb cores, providing a clear reference for their capabilities and design considerations. These parameters are not static but are custom-engineered to meet specific project requirements, underscoring the versatility and adaptability of this material, allowing for a precise balance between structural performance, weight, and cost, ultimately enhancing the overall efficiency and longevity of the final product system.

Fig 2: A magnified view of the precise hexagonal cell structure, illustrating the engineering behind a steel honeycomb core.

Typical Specifications of Stainless Steel Honeycomb Cores (304/316 Grade)

| Parameter | Unit | Typical Range (Standard Products) | Notes |

|---|---|---|---|

| Cell Size (S) | mm (inch) | 3.2 (1/8") - 25.4 (1") | Smaller cells for higher strength; larger for lighter weight. |

| Foil Thickness (t) | mm (inch) | 0.05 (0.002") - 0.2 (0.008") | Thicker foil increases strength and rigidity. |

| Core Height (H) | mm (inch) | 6.35 (0.25") - 300 (12") | Determines sandwich panel stiffness. |

| Density | kg/m³ (lb/ft³) | 32 - 192 (2 - 12) | Highly variable based on cell size and foil thickness. |

| Compressive Strength (L) | MPa (psi) | 2.0 - 20 (300 - 3000) | Measured perpendicular to core surface. |

| Shear Strength (W) | MPa (psi) | 0.5 - 5.0 (70 - 700) | Measured parallel to ribbon direction. |

| Thermal Conductivity | W/(m·K) | 0.1 - 0.5 (typical for air-filled) | Excellent insulation properties due to trapped air. |

| Operating Temperature Range | °C (°F) | -200 to +800 (-328 to +1472) | Material dependent, stainless steel offers wide range. |

Diverse Applications and Emerging Industry Trends

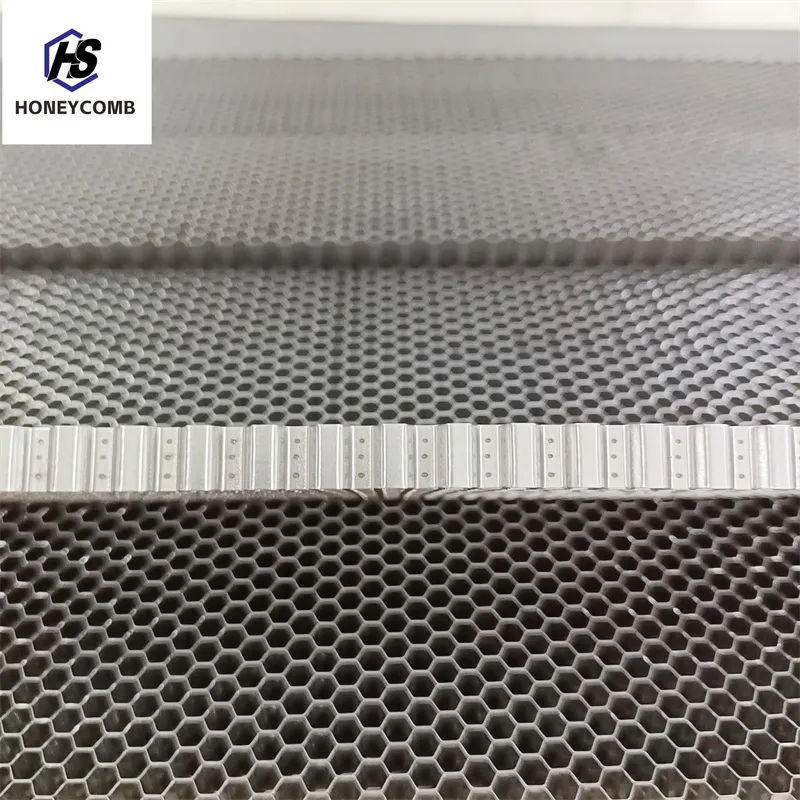

The versatility of the steel honeycomb core positions it as a critical material across an increasingly diverse range of industries, continuously expanding its footprint as technological advancements and environmental imperatives drive innovation. A prime example of its specialized utility is in advanced sewage treatment systems, where our Customized Hexagonal 316 Stainless Steel Honeycomb Core excels. In these demanding environments, the 316 stainless steel provides exceptional corrosion resistance against the aggressive chemical compositions often found in wastewater, ensuring structural integrity and longevity. Within sewage treatment, the honeycomb core can serve as highly efficient media support, providing a robust, stable platform for biological growth in trickling filters or submerged aerated filters, facilitating the removal of pollutants. Its precise cellular structure also allows for optimized fluid distribution and gas exchange, leading to more efficient treatment processes, significant energy savings due to reduced pumping requirements, and improved effluent quality. Beyond this specialized application, the aerospace industry has long been a major adopter, leveraging the incredible strength-to-weight ratio of steel honeycomb core for aircraft flooring, wing components, leading edges, and engine nacelles, where every kilogram saved translates into reduced fuel consumption and increased payload capacity. In the automotive sector, particularly in high-performance vehicles, composite panels utilizing steel honeycomb are increasingly used for chassis components, energy-absorbing crash structures, and even lightweight doors, including advanced honeycomb core steel door designs that offer enhanced security and thermal insulation while reducing vehicle mass. The construction industry benefits from steel honeycomb sheet panels for architectural facades, cleanroom walls, and elevated access flooring, providing flat, stiff, and lightweight solutions with excellent thermal and acoustic properties. Marine applications include bulkheads, decks, and superstructures for yachts and commercial vessels, where corrosion resistance and weight reduction are paramount. Furthermore, in the energy sector, it finds use in heat exchangers and specific reactor components where its high surface area and thermal properties are advantageous. The latest industry trends underscore a strong drive towards lightweighting and sustainability, pushing material science to deliver solutions that are not only performant but also environmentally conscious. The exceptional durability and recyclability of stainless steel honeycomb cores align perfectly with these global trends, making them a material of choice for future-proof engineering solutions that contribute to a circular economy, minimizing waste and resource consumption while maximizing operational efficiency and reducing long-term costs across sectors.

Fig 3: The strategic placement of a steel honeycomb core within an industrial filtration system, showcasing its role in critical infrastructure.

Key Technical Advantages Over Traditional Materials

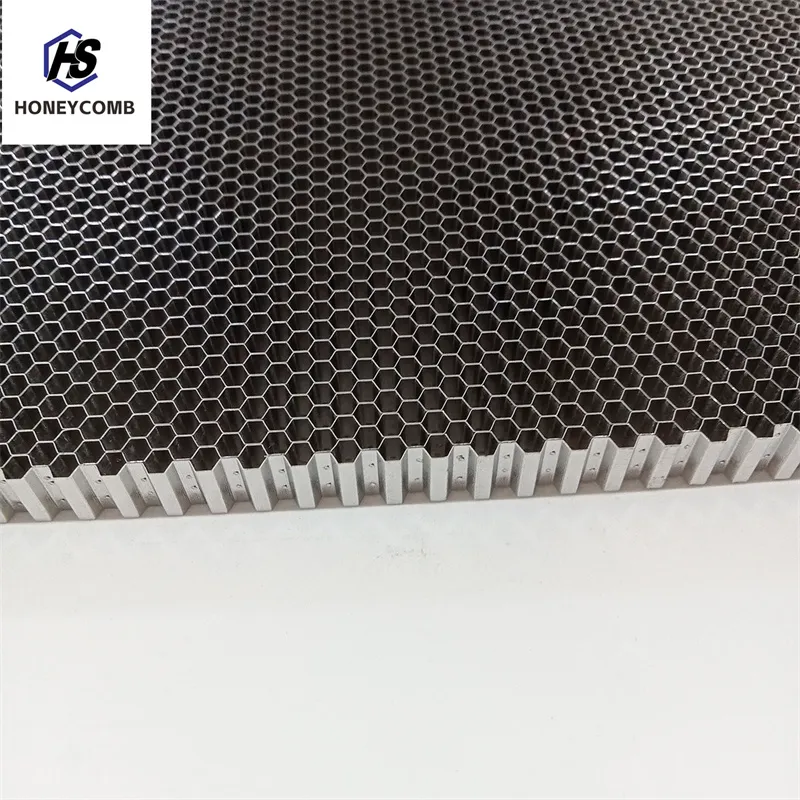

The adoption of steel honeycomb core technology represents a significant leap forward in material engineering, offering a compelling array of technical advantages that traditional solid materials or even some conventional composite structures simply cannot match. Foremost among these is the unparalleled strength-to-weight ratio. By cleverly distributing material into a cellular matrix, a honeycomb structure achieves exceptional rigidity and structural integrity with minimal mass. For example, a sandwich panel constructed with a steel honeycomb core can achieve the bending stiffness of a solid steel plate of equivalent thickness, but at a fraction of the weight, typically a 70-90% weight reduction. This efficiency is critical in industries where weight is directly correlated with operational cost, such as aerospace and transportation. Furthermore, the inherent cellular design provides superior energy absorption and impact resistance. When subjected to an impact, the honeycomb cells deform and crush in a controlled manner, absorbing kinetic energy uniformly across the structure, thereby protecting critical components or occupants. This makes it an ideal material for crashworthiness applications, blast protection, and damping systems. Beyond mechanical performance, the unique structure also imparts excellent thermal and acoustic insulation properties. The numerous small, isolated air pockets within the honeycomb act as barriers to heat transfer, significantly reducing thermal conductivity, which is invaluable in cryogenic applications, high-temperature environments, and energy-efficient building solutions. Similarly, these enclosed air cells effectively trap and dampen sound waves, contributing to significant noise reduction in a variety of applications, from vehicle interiors to industrial machinery enclosures. The corrosion resistance, especially of the 316 stainless steel variant, is a standout feature, making it impervious to many harsh chemicals, saltwater, and environmental degradation that would rapidly compromise other metals. This inherent durability extends the operational lifespan of components and reduces the need for frequent maintenance or replacement, leading to substantial long-term cost savings and improved reliability. Finally, from an environmental perspective, the material efficiency in its manufacturing process, combined with the high recyclability of stainless steel, positions the steel honeycomb core as an environmentally responsible choice, contributing to sustainable engineering practices and reducing the overall carbon footprint of products and structures. These combined advantages underscore why steel honeycomb is increasingly chosen as a preferred material solution for complex, high-performance engineering challenges in the modern industrial landscape.

Fig 4: Demonstrating the lightweight and energy-absorbing capabilities of a steel honeycomb core in a dynamic application.

Customization and Bespoke Engineering Solutions

One of the most compelling aspects of the steel honeycomb core is its remarkable adaptability and the extensive possibilities for customization, allowing it to be precisely tailored to meet the unique and often highly specific demands of diverse engineering projects. Unlike off-the-shelf components, honeycomb cores can be meticulously engineered by adjusting various parameters to achieve optimal performance characteristics for a given application. Key customizable parameters include cell size, which directly influences strength, stiffness, and density; foil thickness, allowing for fine-tuning of mechanical properties and overall weight; and core height, which impacts the flexural rigidity of a sandwich panel. Furthermore, the selection of the steel grade is crucial, with options ranging from 304 stainless steel for general corrosion resistance to 316 stainless steel for enhanced resistance to chlorides and acidic environments, as exemplified by our Customized Hexagonal 316 Stainless Steel Honeycomb Core designed for aggressive sewage treatment conditions. Beyond these structural modifications, customization can extend to the overall shape and dimensions of the core, allowing for intricate geometries to fit complex designs, which is often achieved through advanced CNC cutting and forming techniques. Surface treatments, such as passivation for improved corrosion resistance or specialized coatings for enhanced bonding with facing materials, also offer additional layers of customization. The essence of successful honeycomb application often lies in a collaborative engineering approach between the client and the manufacturer. This involves detailed consultation, finite element analysis (FEA), and prototyping to ensure the customized solution precisely addresses performance requirements, environmental conditions, and budgetary constraints. This bespoke approach ensures that the client receives a steel honeycomb core that is not just a component, but an optimized engineering solution that integrates seamlessly into their system, providing maximum efficiency, longevity, and return on investment. The ability to fine-tune every aspect of the honeycomb core from its fundamental material composition to its final form factor is what elevates it from a mere material to a strategic design element in cutting-edge engineering.

Fig 5: A custom-fabricated steel honeycomb core, showcasing the precision and versatility of tailored engineering solutions.

Illustrative Application Case Studies and Success Stories

The theoretical advantages of steel honeycomb core materials are best evidenced by their successful deployment in real-world applications across diverse sectors. These case studies highlight not only the versatility of the material but also the tangible benefits it delivers to complex engineering challenges. Consider, for instance, a large-scale municipal sewage treatment plant facing severe corrosion issues with its existing media support structures, leading to frequent maintenance downtimes and compromised treatment efficiency. By replacing conventional materials with our Customized Hexagonal 316 Stainless Steel Honeycomb Core, the plant achieved a remarkable transformation. The 316 stainless steel provided superior resistance to the aggressive chemical environment, extending the media’s lifespan from an average of 5 years to over 20 years. Furthermore, the optimized hexagonal cellular structure facilitated better wastewater distribution and aeration, resulting in a 15% improvement in biochemical oxygen demand (BOD) reduction and a 10% decrease in energy consumption for aeration, translating into significant operational cost savings and improved environmental compliance. Another compelling example comes from the aerospace industry, where a leading aircraft manufacturer sought to reduce the weight of internal fuselage components without compromising structural integrity. By designing sandwich panels with a specialized lightweight steel honeycomb core and carbon fiber skins, they achieved a cumulative weight reduction of over 300 kg per aircraft. This weight saving directly contributed to an estimated 1-2% improvement in fuel efficiency, a critical metric for airline profitability, and extended the aircraft’s operational range, showcasing the direct economic benefits of intelligent material selection. In the architectural sector, a prestigious high-security building project required robust, yet aesthetically pleasing, insulated doors. Conventional solid steel doors were too heavy and presented thermal bridging issues. The solution involved developing custom honeycomb core steel door panels, which integrated a high-density stainless steel honeycomb core between two heavy-gauge steel sheets. This design resulted in doors that were significantly lighter than solid steel alternatives, easier to install, and provided superior ballistic protection and thermal insulation (U-value reduced by 25%), while maintaining a sleek, modern aesthetic. Client feedback consistently emphasized the improved performance, reduced installation complexity, and the longevity of these advanced doors, validating the design choice. These cases underscore that the benefits of steel honeycomb core extend beyond mere material properties; they translate into enhanced performance, reduced operational costs, extended asset lifespans, and improved sustainability across a wide spectrum of industrial and commercial applications, solidifying its position as a go-to solution for forward-thinking engineering projects globally.

Choosing the Right Manufacturer: A Critical Comparison

Selecting the appropriate manufacturer for steel honeycomb core products is a pivotal decision that directly impacts the quality, performance, and long-term success of any project. The market offers various suppliers, but not all possess the specialized expertise, production capabilities, and commitment to quality necessary for delivering high-performance, reliable solutions. Key factors to consider during evaluation include the manufacturer's technical expertise and experience in honeycomb core fabrication; their adherence to international quality control standards such as ISO 9001:2015, which ensures consistent product quality and process reliability; and their range of certifications like ASTM for material properties or specific industry standards relevant to your application. Furthermore, a manufacturer's R&D capabilities are indicative of their commitment to innovation and their ability to develop customized solutions for unique challenges, such as the tailored hexagonal 316 stainless steel honeycomb core for sewage treatment that addresses specific corrosive environments. Production capacity and lead times are also crucial considerations, especially for large-scale projects or those with tight deadlines. A reputable manufacturer should be able to provide clear, realistic production schedules and demonstrate robust supply chain management. Perhaps most importantly, the level of after-sales support, including technical assistance, troubleshooting, and warranty commitments, reflects a manufacturer’s dedication to client success and long-term partnerships. Below is a comparative overview, contrasting generic manufacturers with the distinct advantages offered by a specialist like HSHI Honeycomb, highlighting our strengths in key areas that matter most to B2B clients seeking reliable and customized steel honeycomb core solutions. This comparison aims to guide decision-makers towards partners who not only supply materials but also offer comprehensive engineering support and a proven track record of excellence in delivering complex projects on time and to specification, thereby minimizing risks and maximizing return on investment for sophisticated industrial applications.

Manufacturer Comparison: Standard vs. Specialized (HSHI Honeycomb)

| Feature | Generic Manufacturer | HSHI Honeycomb (Specialized) |

|---|---|---|

| Product Range | Standard sizes, limited material grades (e.g., only 304). | Extensive customization (cell size, foil, height, shape), various grades (316, 304, etc.), specialized products like our Hexagonal 316 SS Core. |

| Quality Control & Certs | Basic QC, limited certifications. | Rigorous ISO 9001:2015 certified processes, comprehensive material testing (ASTM), adherence to relevant industry standards (ANSI), traceable supply chain. |

| Technical Expertise & R&D | Standard technical support, minimal R&D. | Dedicated R&D team, deep engineering knowledge, collaborative design and simulation (FEA) support, capable of bespoke material solutions. |

| Project Lead Times | Variable, potentially longer for custom orders. | Optimized production lines for efficiency, reliable lead times even for complex custom orders, clear communication. |

| Customer Support | Basic post-sales support. | Comprehensive technical support, dedicated account management, clear warranty and after-sales service, long-term partnership focus. |

| Application Focus | General applications. | Specialized solutions for demanding environments (e.g., sewage treatment), high-performance sectors (aerospace, marine, automotive, defense). |

Fig 6: Rigorous quality control measures, emphasizing the commitment to precision and performance in steel honeycomb core manufacturing.

Ensuring Trust and Reliability: Our Commitment to Excellence

At HSHI Honeycomb, our reputation as a trusted leader in the advanced material sector, particularly for steel honeycomb core solutions, is built upon an unwavering commitment to expertise, authoritativeness, and trustworthiness. Our extensive service history, spanning over two decades in the industry, is a testament to our profound understanding of material science, precision engineering, and the diverse needs of our global clientele. We operate under stringent quality management systems, evidenced by our ISO 9001:2015 certification, ensuring that every product, from standard steel honeycomb sheet to specialized Customized Hexagonal 316 Stainless Steel Honeycomb Core, consistently meets or exceeds international quality benchmarks. Our authoritative position is further reinforced by strategic partnerships with leading research institutions and industry bodies, alongside substantial investments in cutting-edge R&D, allowing us to continuously innovate and push the boundaries of honeycomb technology. We actively participate in shaping industry best practices and standards, leveraging our deep expertise to deliver solutions that are not only performant but also future-proof. Trustworthiness is at the core of our operations. We offer complete transparency regarding our manufacturing processes, material sourcing, and quality assurance protocols. Our dedicated customer support team provides comprehensive technical assistance throughout the project lifecycle, from initial consultation and design optimization to post-delivery support. We understand the critical nature of project timelines; therefore, our delivery cycles are meticulously planned and communicated, typically ranging from 4-6 weeks for custom orders after design finalization, depending on complexity and material availability, with expedited options available for urgent requirements. Furthermore, we stand behind the durability and performance of our products with robust quality assurance protocols and comprehensive warranty commitments, ensuring peace of mind for our clients. We invite prospective partners to explore our extensive portfolio, review our certifications, and engage with our technical experts to understand how our unparalleled commitment to excellence can contribute to the success and longevity of their most challenging engineering endeavors.

Frequently Asked Questions (FAQ)

Q1: What are the typical lead times for custom steel honeycomb core orders?

A1: For custom orders, lead times typically range from 4 to 6 weeks, depending on the complexity of the design, specific material requirements (e.g., specialized 316 stainless steel grades), and current production schedule. We strive to provide accurate estimates early in the project and maintain transparent communication throughout the manufacturing process to ensure timely delivery.

Q2: What inspection standards do your steel honeycomb core products adhere to?

A2: Our products adhere to strict international quality and performance standards, including ISO 9001:2015 for quality management systems. Material properties are verified according to ASTM standards, and dimensional tolerances meet ANSI specifications where applicable. We also conduct in-house rigorous testing, including compressive and shear strength tests, and provide material certificates upon request.

Q3: Can you provide design assistance for specific applications, such as a honeycomb core steel door?

A3: Absolutely. Our team of experienced engineers and technical specialists offers comprehensive design assistance. We collaborate closely with clients from conceptualization through to production, utilizing advanced simulation tools like FEA to optimize honeycomb parameters (cell size, foil thickness, material grade) for your specific application requirements, ensuring optimal performance and cost-efficiency for products like honeycomb core steel doors or aerospace components.

Q4: What are the warranty terms for your steel honeycomb core products?

A4: We provide a comprehensive warranty against manufacturing defects and material non-conformance for a specified period from the date of delivery. Specific warranty terms are detailed in our sales agreements and can be tailored to project specifics. Our commitment is to ensure the highest quality and customer satisfaction.

Q5: How does your Customized Hexagonal 316 Stainless Steel Honeycomb Core benefit sewage treatment plants?

A5: Our Customized Hexagonal 316 Stainless Steel Honeycomb Core offers significant benefits for sewage treatment plants due to its superior corrosion resistance in aggressive chemical environments, extended lifespan reducing maintenance and replacement costs, and optimized cellular structure that enhances fluid distribution and supports efficient biological media for improved pollutant removal and energy savings. Its robust design ensures long-term operational reliability in demanding wastewater applications.

Conclusion: Pioneering the Future with Steel Honeycomb Core

The journey through the capabilities and applications of the steel honeycomb core reveals a material that is far more than just a structural component; it is an enabler of advanced engineering, a catalyst for innovation, and a cornerstone of sustainable design across an ever-widening array of industries. From its meticulous manufacturing process, ensuring precision and integrity, to its versatile technical parameters that can be precisely tailored for bespoke solutions, the steel honeycomb core offers a compelling suite of advantages. Its unparalleled strength-to-weight ratio, exceptional energy absorption, and superior thermal and acoustic insulation properties make it an indispensable choice for sectors prioritizing efficiency, safety, and longevity. The specific utility of solutions like our Customized Hexagonal 316 Stainless Steel Honeycomb Core for sewage treatment exemplifies its critical role in addressing specialized industrial challenges, demonstrating robust corrosion resistance and enhanced operational efficiency in demanding environments. As industries globally grapple with the dual challenges of performance optimization and environmental stewardship, the demand for lightweight, high-strength, and durable materials will only intensify. The steel honeycomb core, with its inherent recyclability and contribution to reduced energy consumption through weight reduction, stands ready to meet these future demands, playing a pivotal role in the development of next-generation aircraft, vehicles, infrastructure, and industrial processes. Companies that embrace this advanced material will not only gain a competitive edge but also contribute significantly to a more sustainable and technologically advanced future. Engaging with a specialized manufacturer like HSHI Honeycomb, who embodies the highest standards of expertise, authoritativeness, and trustworthiness, ensures access to not just a product, but a comprehensive engineering solution that is designed for excellence and built for the future.

Industry Insights and Further Reading

For those seeking deeper technical insights and a broader understanding of advancements in honeycomb materials, the following resources and academic publications offer valuable perspectives on research, applications, and future trends in composite structures:

-

Journal of Composite Materials: This journal frequently publishes peer-reviewed articles on the mechanical properties, manufacturing techniques, and application-specific performance of various honeycomb structures, including those made from steel and other alloys.

https://journals.sagepub.com/home/jcm -

Materials & Design: An international journal that covers original research on the selection, design, processing, and performance of materials, often featuring studies on novel applications of honeycomb structures in advanced engineering.

https://www.sciencedirect.com/journal/materials-and-design -

Aerospace America Magazine (AIAA): Offers insights into the latest developments in aerospace technology, including lightweighting strategies and advanced materials like steel honeycomb for aircraft and spacecraft structures.

https://aerospaceamerica.aiaa.org/ -

The Fabricator: While not exclusively academic, this publication often features practical articles and case studies on advanced metal fabrication techniques, including those relevant to the production of high-performance steel structures.

https://www.thefabricator.com/

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025