- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 25, 2025 05:38

Back to list

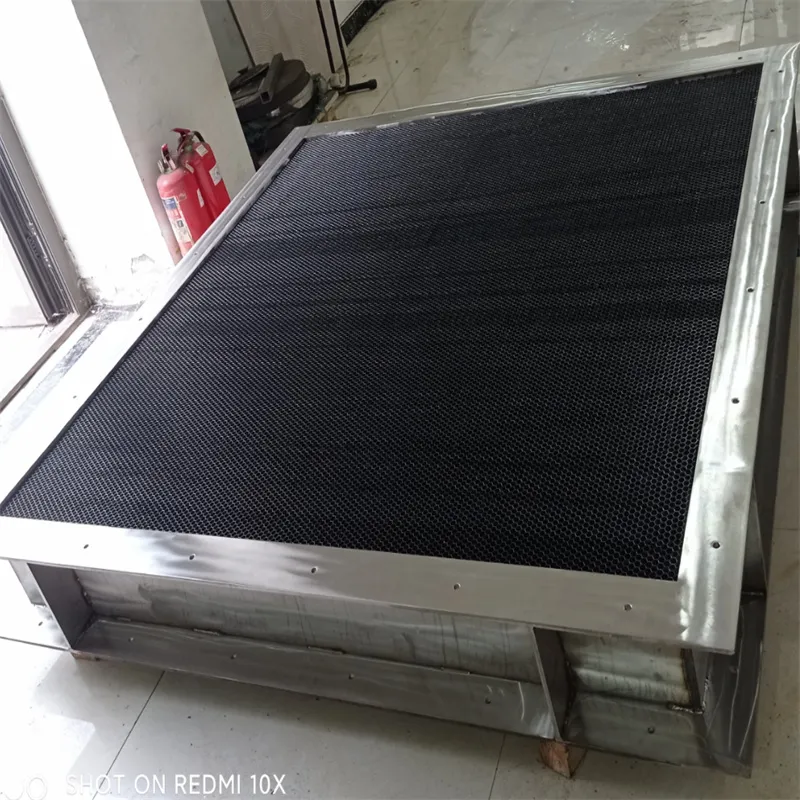

EMIEMC/RF Shielding Honeycomb Vent

The realm of electromagnetic interference (EMI) and radio frequency interference (RFI) shielding is critical for maintaining the integrity of electronic systems. One technology that has stood out in this field is the shielded waveguide ventilation systems. These systems are increasingly pivotal, serving as silent guardians in protecting sensitive electronic equipment from disruptive external and internal electromagnetic disturbances.

The trustworthiness of shielded waveguide solutions is further evidenced by documented performance in rigorous environments. Whether within a shielded room of a testing facility or integrated into the fuselage of an aircraft, these systems are proven to withstand complex operational challenges while maintaining performance, ensuring peace of mind for end-users. Case studies showcase their deployment in battlefield communication settings, where failure is not an option, underlining the real-world effectiveness of these vents. These examples reveal not only the technical prowess involved in creating and implementing shielded waveguide systems but also their crucial role in augmenting the performance and longevity of critical electronic infrastructure. In evaluating the shielded waveguide vents for EMI/RFI protection, potential buyers should consider the breadth of expertise and experience evident in product offerings. It's crucial to engage with manufacturers who demonstrate a clear understanding of shielding requirements, and who offer products verified by technical standards and validated through extensive field use. Trust in these products is built on a foundation of proven expertise, detailed research, and a consistent record of success in diverse and demanding applications. Professionals seeking optimal EMI/RFI protection will find that shielded waveguide ventilation systems provide unparalleled integration of functionality and shielding capability. With ongoing advances, these systems are setting new benchmarks in how sensitive environments manage electromagnetic challenges, confirming their essential role in today's technology-driven world.

The trustworthiness of shielded waveguide solutions is further evidenced by documented performance in rigorous environments. Whether within a shielded room of a testing facility or integrated into the fuselage of an aircraft, these systems are proven to withstand complex operational challenges while maintaining performance, ensuring peace of mind for end-users. Case studies showcase their deployment in battlefield communication settings, where failure is not an option, underlining the real-world effectiveness of these vents. These examples reveal not only the technical prowess involved in creating and implementing shielded waveguide systems but also their crucial role in augmenting the performance and longevity of critical electronic infrastructure. In evaluating the shielded waveguide vents for EMI/RFI protection, potential buyers should consider the breadth of expertise and experience evident in product offerings. It's crucial to engage with manufacturers who demonstrate a clear understanding of shielding requirements, and who offer products verified by technical standards and validated through extensive field use. Trust in these products is built on a foundation of proven expertise, detailed research, and a consistent record of success in diverse and demanding applications. Professionals seeking optimal EMI/RFI protection will find that shielded waveguide ventilation systems provide unparalleled integration of functionality and shielding capability. With ongoing advances, these systems are setting new benchmarks in how sensitive environments manage electromagnetic challenges, confirming their essential role in today's technology-driven world.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025