- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 25, 2025 20:18

Back to list

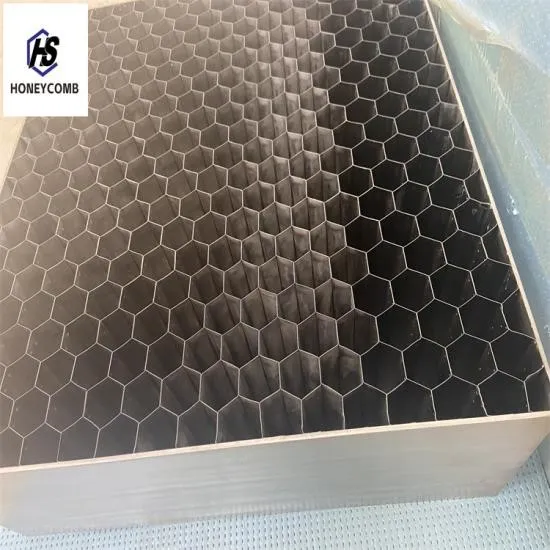

vents en nid d'abeille

Vents in hexagonal structures, commonly referred to as honeycomb vents, have taken significant strides in modern engineering and industrial applications. These uniquely structured vents excel in multiple domains owing to their distinctive characteristics derived from the quintessential honeycomb design. This particular architecture offers an exemplary blend of structural integrity, lightweight efficiency, and superior airflow management, making it a preferred choice in fields like aerospace, automotive, architecture, and more.

The trustworthiness of honeycomb vents is further reinforced by their performance in extreme conditions. In industries such as chemical processing and defense, where safety and reliability are paramount, these vents provide robust solutions. Their inherent design allows for efficient dissipation of heat, effective containment of hazardous fumes, and robustness against physical stresses. This reliability has been documented through rigorous testing and real-world deployments, proving indispensable in preventing accidents and maintaining safety standards. In addition to their practical benefits, honeycomb vents are increasingly being spotlighted for their contributions to innovation in product development. Manufacturers adopting advanced materials like aluminum and carbon composites in honeycomb vent production find that the combination results in a superior product capable of outperforming conventional vent systems. This integration of material sciences and design innovation marks a new era in industrial applications, where honeycomb structures are paving the way for future-ready solutions. To maintain a competitive edge in product manufacturing, businesses are investing heavily in Research and Development specific to honeycomb technology. As experts in material science and design engineering continue to expand the boundaries of what these structures can achieve, companies employing honeycomb vents are witnessing unprecedented advances in their product offerings. This relentless pursuit of innovation not only enhances product capabilities but also strengthens the market position of companies that are early adopters of this transformative technology. In conclusion, the adoption and integration of honeycomb vents represent a paradigm shift across multiple industries. Their multifaceted advantages, supported by robust expert testimonials and backed by empirical data, make them a worthy investment for organizations aiming to enhance their product offerings through reliable, efficient, and innovative solutions. The future of industrial design and engineering is destined to be reshaped by the continued evolution of honeycomb technologies, promising a future replete with possibilities yet to be imagined. By embracing honeycomb vents, industries not only solve immediate challenges but also position themselves at the forefront of the next wave of industrial evolution.

The trustworthiness of honeycomb vents is further reinforced by their performance in extreme conditions. In industries such as chemical processing and defense, where safety and reliability are paramount, these vents provide robust solutions. Their inherent design allows for efficient dissipation of heat, effective containment of hazardous fumes, and robustness against physical stresses. This reliability has been documented through rigorous testing and real-world deployments, proving indispensable in preventing accidents and maintaining safety standards. In addition to their practical benefits, honeycomb vents are increasingly being spotlighted for their contributions to innovation in product development. Manufacturers adopting advanced materials like aluminum and carbon composites in honeycomb vent production find that the combination results in a superior product capable of outperforming conventional vent systems. This integration of material sciences and design innovation marks a new era in industrial applications, where honeycomb structures are paving the way for future-ready solutions. To maintain a competitive edge in product manufacturing, businesses are investing heavily in Research and Development specific to honeycomb technology. As experts in material science and design engineering continue to expand the boundaries of what these structures can achieve, companies employing honeycomb vents are witnessing unprecedented advances in their product offerings. This relentless pursuit of innovation not only enhances product capabilities but also strengthens the market position of companies that are early adopters of this transformative technology. In conclusion, the adoption and integration of honeycomb vents represent a paradigm shift across multiple industries. Their multifaceted advantages, supported by robust expert testimonials and backed by empirical data, make them a worthy investment for organizations aiming to enhance their product offerings through reliable, efficient, and innovative solutions. The future of industrial design and engineering is destined to be reshaped by the continued evolution of honeycomb technologies, promising a future replete with possibilities yet to be imagined. By embracing honeycomb vents, industries not only solve immediate challenges but also position themselves at the forefront of the next wave of industrial evolution.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025