- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 10:25

Back to list

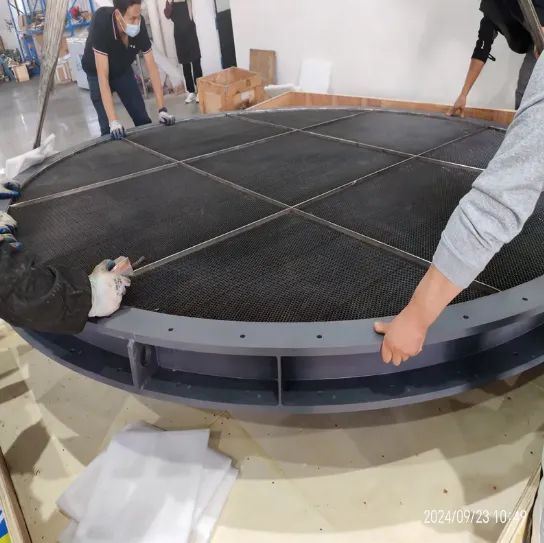

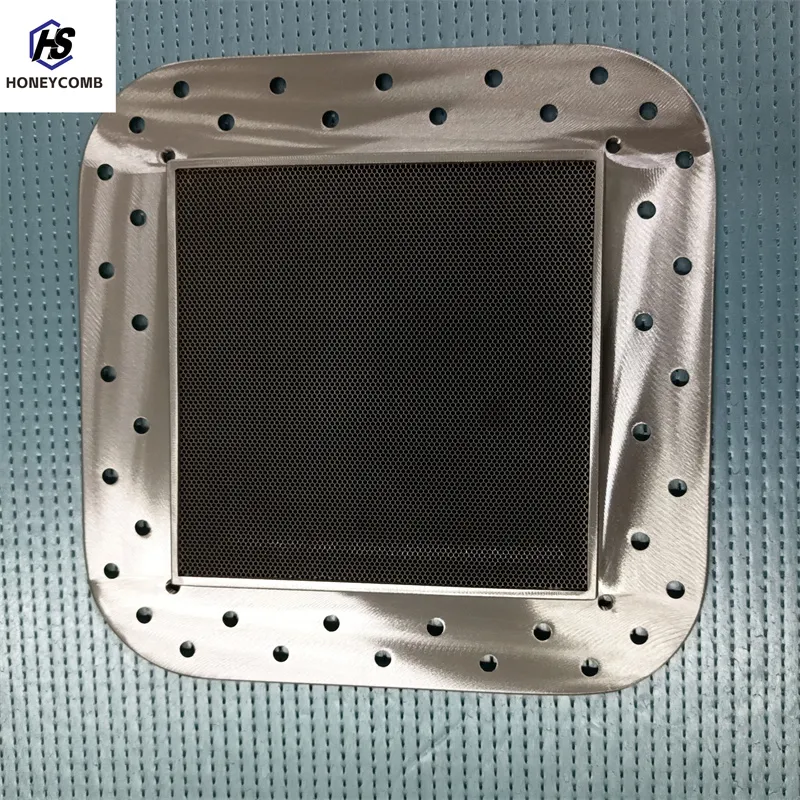

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

Vetro rivestito ito, a term that might perplex many, holds significant importance for industries relying on advanced glass products. This term typically refers to a specific type of coated glass material known for its enhanced durability, aesthetic appeal, and versatile applications. With an increasingly globalized industry focusing on sustainability and design, the adoption of premium glass products such as vetro rivestito ito positions companies at the forefront of innovation.

Trustworthiness in products labeled as vetro rivestito ito is paramount. Manufacturers need to provide transparency in sourcing materials and production methodologies to establish consumer confidence. Certifications and adherence to international quality standards like ISO further solidify trust with stakeholders and end-users. Businesses integrating vetro rivestito ito into their product lines often share success stories that emphasize a seamless blend of design and functionality. Architectural firms, for example, laud the use of this glass for creating façades that boast both energy efficiency and modern aesthetics. Interior designers also recognize this material's potential in contributing to ambient lighting solutions due to its reflective properties, which add to an environment's ambiance without significant energy costs. The future for vetro rivestito ito appears promising as research continues to expand its applications. Developments are being made toward making ito coatings more environmentally friendly, such as reducing the dependency on rare and expensive materials like indium. Industries are committed to sustainability, seeking innovative approaches that align with eco-friendly norms. In conclusion, vetro rivestito ito stands out as a high-value material combining aesthetic versatility with technological sophistication. Companies and researchers committed to its advancement fortify their position in a rapidly evolving market landscape. As this material adapts to emerging needs, ranging from energy solutions to digital technology interfaces, its role as a pivotal component in industry innovation is undeniable. The expertise developed around its production and application not only demonstrates profound technical capabilities but also assures a trusted pathway to future advancements.

Trustworthiness in products labeled as vetro rivestito ito is paramount. Manufacturers need to provide transparency in sourcing materials and production methodologies to establish consumer confidence. Certifications and adherence to international quality standards like ISO further solidify trust with stakeholders and end-users. Businesses integrating vetro rivestito ito into their product lines often share success stories that emphasize a seamless blend of design and functionality. Architectural firms, for example, laud the use of this glass for creating façades that boast both energy efficiency and modern aesthetics. Interior designers also recognize this material's potential in contributing to ambient lighting solutions due to its reflective properties, which add to an environment's ambiance without significant energy costs. The future for vetro rivestito ito appears promising as research continues to expand its applications. Developments are being made toward making ito coatings more environmentally friendly, such as reducing the dependency on rare and expensive materials like indium. Industries are committed to sustainability, seeking innovative approaches that align with eco-friendly norms. In conclusion, vetro rivestito ito stands out as a high-value material combining aesthetic versatility with technological sophistication. Companies and researchers committed to its advancement fortify their position in a rapidly evolving market landscape. As this material adapts to emerging needs, ranging from energy solutions to digital technology interfaces, its role as a pivotal component in industry innovation is undeniable. The expertise developed around its production and application not only demonstrates profound technical capabilities but also assures a trusted pathway to future advancements.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025