- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

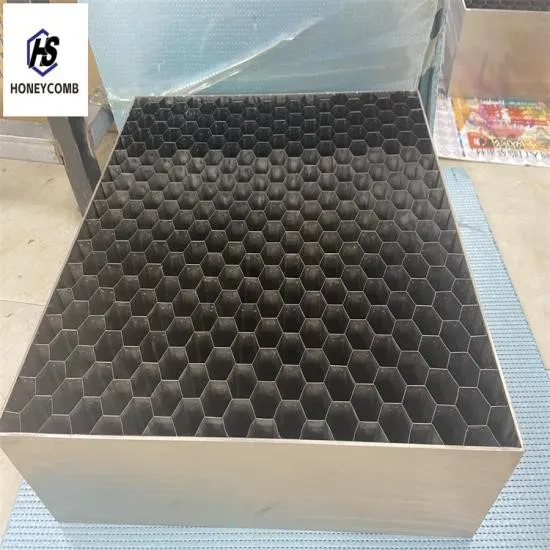

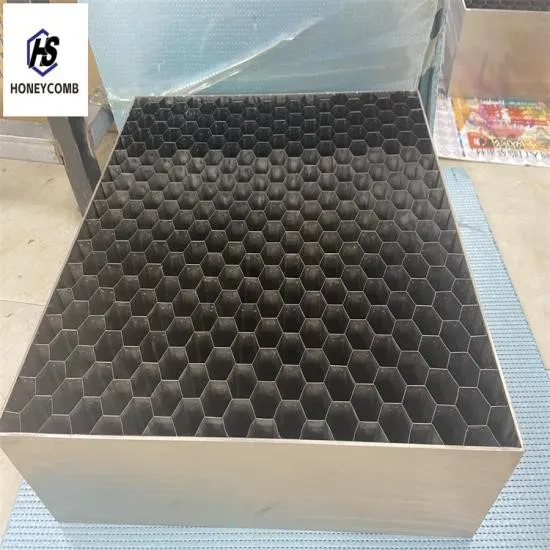

Honeycomb Stainless Steel Air Flow Straightener - Hengshi | Aerodynamic Testing, EMI Shielding

The air flow straightener has emerged as a critical component in modern aerodynamic research, enabling accurate airflow measurement and turbulence control. This article delves into the technical specifications, applications, and industry significance of the wind tunnel honeycomb, produced by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. As a leader in high-quality shielding products, Hengshi's offerings play a pivotal role in advancing aerospace, automotive, and industrial testing standards.

Product Introduction

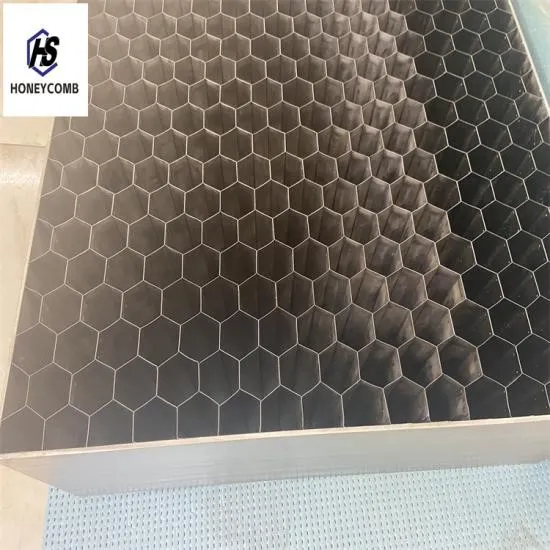

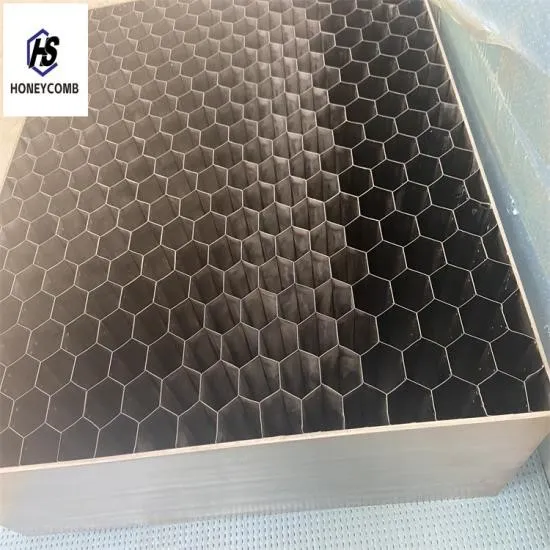

The Honeycomb Stainless Steel Air Flow Straightener is engineered to transform turbulent airflow into laminar flow, ensuring precision in aerodynamic testing. This technology, widely adopted in aerospace, automotive, and industrial sectors, stabilizes air velocity and minimizes turbulence, making it indispensable for accurate data collection in wind tunnels. The product's design incorporates a matrix of thin-walled cells, allowing up to 95-99% open area while maintaining structural integrity. This balance of efficiency and durability positions it as a preferred solution for demanding applications.

Key Features and Technical Specifications

The Steel Honeycomb Wind Tunnel is available in a variety of materials, including 304 stainless steel, 316L, and Hastelloy X, catering to diverse environmental and performance requirements. Its specifications are tailored to meet rigorous industry standards, ensuring compatibility with both high-speed and precision testing environments.

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30 mm (as required) |

| Thickness | Customized |

| Shape | Customized (as required) |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defence, gas seals, communications, medical, and other industries. |

Applications in Aerodynamic Testing

The Honeycomb Air Flow Straightener is a cornerstone of wind tunnel technology, which is essential for studying aerodynamic effects. Wind tunnels simulate real-world airflow conditions, enabling engineers to test the performance of vehicles, aircraft, and structures. According to the National Institute of Standards and Technology (NIST), wind tunnel testing adheres to stringent protocols to ensure data accuracy and repeatability [1].

These straighteners are particularly critical in the aerospace industry, where they are used to test the aerodynamics of aircraft, missiles, and spacecraft. By reducing turbulence, they allow for precise measurement of lift, drag, and pressure distribution. In the automotive sector, the wind tunnel honeycomb ensures accurate data collection for optimizing vehicle design and fuel efficiency. Additionally, it is employed in the testing of high-speed trains, ships, and buildings to evaluate their resistance to wind and environmental stresses.

Advantages of Hengshi's Honeycomb Technology

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a trusted provider of high-performance air flow straightener solutions. The company's products offer several advantages:

- High Shielding Effectiveness: The honeycomb structure provides robust electromagnetic interference (EMI) shielding, protecting sensitive equipment from external noise.

- Corrosion Resistance: Constructed from stainless steel and other durable materials, the straighteners withstand harsh environments without degradation.

- Low Pressure Drop: The 95-99% open area minimizes airflow resistance, ensuring efficient operation in high-speed testing scenarios.

- Customization: Hengshi offers tailored solutions to meet specific project requirements, including unique dimensions, surface treatments, and materials.

Industry Applications and Case Studies

The versatility of the Honeycomb Stainless Steel Air Flow Straightener extends across multiple industries. In the defense sector, it is used for testing missile aerodynamics and structural integrity. For example, cruise missiles and air-to-air missiles rely on precise airflow control to ensure accurate trajectory and performance. In the renewable energy field, the straightener is employed in wind turbine testing to optimize blade efficiency and reduce mechanical stress.

In the medical industry, the wind tunnel honeycomb is utilized in the development of advanced ventilation systems, ensuring sterile environments in operating rooms and laboratories. Its sound insulation properties also make it suitable for noise-sensitive applications, such as data centers and research facilities.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Founded as a leader in precision engineering, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. specializes in producing high-quality shielding products, including ventilation panels, steel honeycomb cores, and honeycomb air flow straighteners. With a commitment to innovation and customer satisfaction, the company has become a preferred partner for industries requiring reliable and durable solutions.

Hengshi's products are certified under ISO9001 and RoHS standards, ensuring compliance with global quality and environmental regulations. The company's state-of-the-art manufacturing facilities and skilled workforce enable it to deliver customized solutions that meet the evolving demands of the market. By integrating advanced welding technologies such as spot welding and vacuum brazing, Hengshi ensures the structural integrity and longevity of its products.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener represents a significant advancement in aerodynamic testing and industrial applications. Its ability to stabilize airflow, reduce turbulence, and withstand harsh conditions makes it an essential tool for engineers and researchers. As the demand for precision in aerospace, automotive, and energy sectors continues to grow, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. remains at the forefront of innovation, delivering solutions that meet the highest standards of performance and reliability.

References

[1] National Institute of Standards and Technology (NIST) – Standards and Testing Protocols for Aerodynamic Research.

Product Images

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025