- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

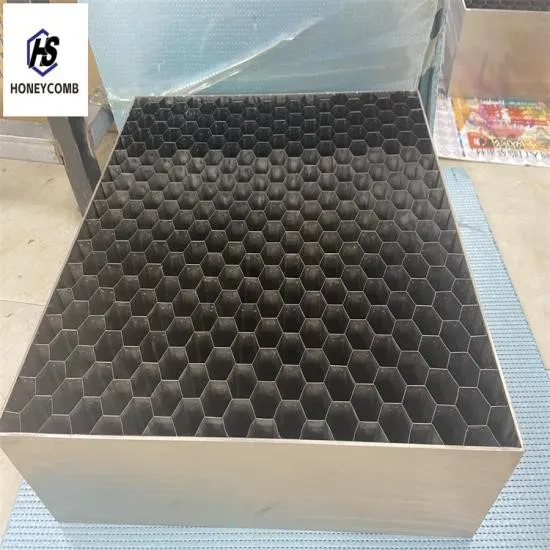

Honeycomb Stainless Steel Air Flow Straightener - Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Product Introduction

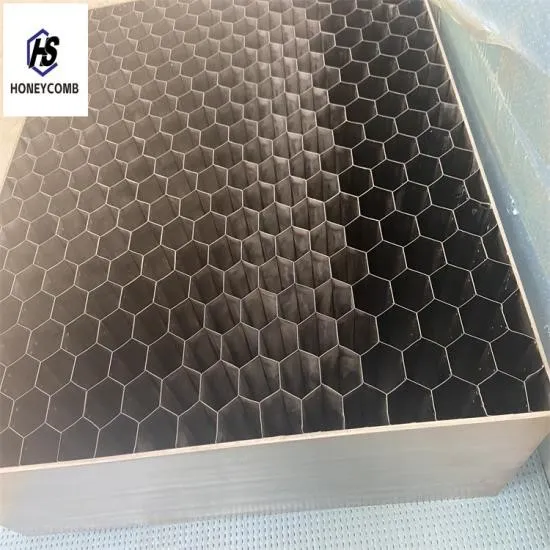

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in modern aerodynamic testing, designed to stabilize airflow and ensure precise measurements. This innovative product has been widely used in various industries, including automotive, aerospace, and marine engineering, to transform turbulent airflow into laminar flow. By achieving a maximum open area of 95-99%, the honeycomb structure minimizes pressure drop and turbulence, making it ideal for high-accuracy applications.

The Steel Honeycomb Wind Tunnel complements this technology by providing a controlled environment for studying aerodynamic effects. Wind tunnels are essential tools for testing the performance of vehicles, aircraft, and structures under simulated airflow conditions. The integration of honeycomb air flow straighteners within these tunnels ensures consistent and reliable data collection, which is vital for research and development in engineering fields.

Key Features and Technical Specifications

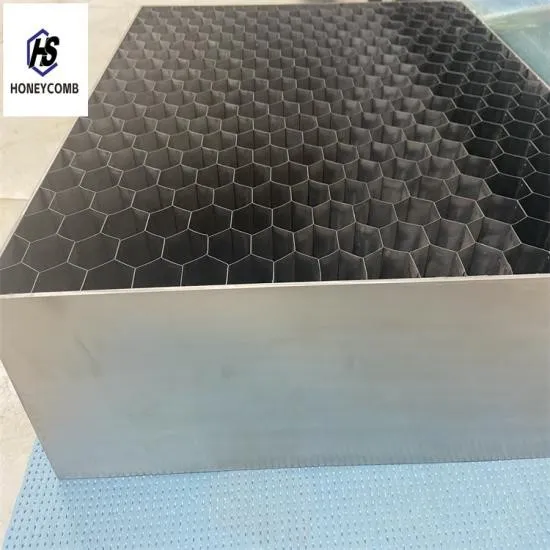

The Honeycomb Stainless Steel Air Flow Straightener is engineered with advanced materials and manufacturing techniques to deliver exceptional performance. Here are the key specifications:

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30 mm (as required) |

| Thickness | Customized |

| Shape | Customized (as required) |

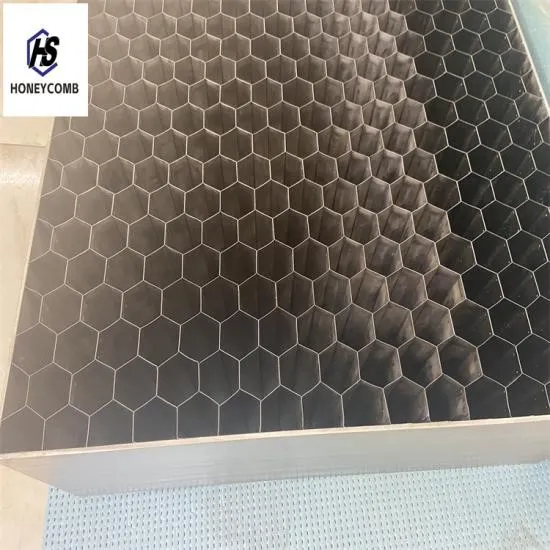

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defense, gas seals, communications, medical, and other industries |

Applications in Diverse Industries

The versatility of the Honeycomb Air Flow Straightener makes it indispensable in various sectors. In the automotive industry, it is used to test aerodynamic effects, air resistance, and pressure resistance of vehicles. For aerospace applications, the product plays a crucial role in evaluating the performance of aircraft, missiles, and other airborne vehicles. The honeycomb structure ensures that airflow is stabilized, allowing engineers to gather accurate data for design improvements.

In the maritime sector, the Steel Honeycomb Wind Tunnel is employed to test the aerodynamic properties of ships and high-speed trains. Additionally, the product is utilized in the construction industry to assess the structural integrity of buildings under various airflow conditions. Its ability to reduce turbulence and maintain laminar flow makes it a preferred choice for researchers and engineers working on complex projects.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Founded as a leader in the production of high-quality shielding products, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a trusted name in the industry. The company specializes in manufacturing ventilation panels, steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals. With a commitment to innovation and quality, Hengshi ensures that its products meet stringent industry standards, including ISO9001 and RoHS certifications.

As a manufacturer with a global presence, Hengshi caters to a wide range of industries, from aerospace to medical equipment. The company's state-of-the-art facilities and experienced team enable it to deliver customized solutions that address the unique needs of its clients. By leveraging advanced technologies and sustainable practices, Hengshi continues to set benchmarks in the precision machinery manufacturing sector.

Why Choose Hengshi's Honeycomb Products?

Choosing Hengshi's Honeycomb Stainless Steel Air Flow Straightener and Steel Honeycomb Wind Tunnel offers numerous advantages. The products are designed to provide high shielding effectiveness, excellent anti-corrosion properties, and superior sound insulation. Their high ventilation efficiency ensures optimal airflow, making them ideal for applications that require precise control over environmental conditions.

Moreover, Hengshi's commitment to quality is evident in its rigorous testing and certification processes. The company's products are manufactured using advanced welding technologies, such as spot welding and vacuum brazing, ensuring durability and reliability. With a focus on customer satisfaction, Hengshi offers customized solutions tailored to meet specific requirements, making it a preferred partner for businesses worldwide.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener and Steel Honeycomb Wind Tunnel represent the pinnacle of engineering excellence in aerodynamic testing. With their ability to stabilize airflow and enhance measurement accuracy, these products are essential for research and development in various industries. Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. continues to lead the way in providing innovative solutions that meet the evolving needs of the market.

References

According to the National Institute of Standards and Technology (NIST), precise measurements are crucial in engineering applications. For more information, visit NIST's official website.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025